Cross-shaft type universal coupling with spline pair

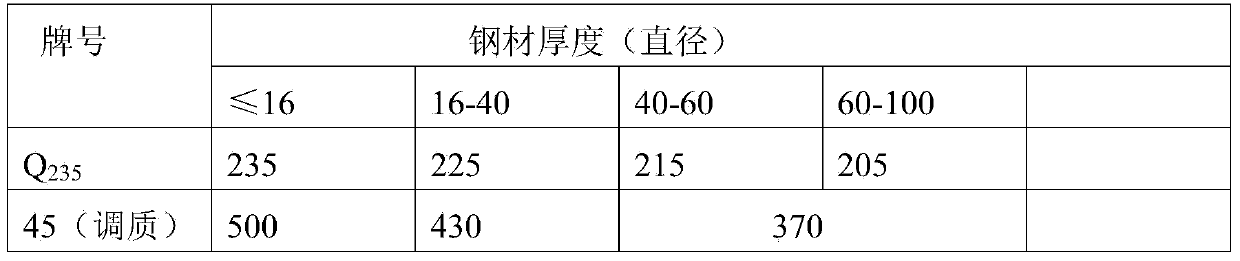

A universal coupling and cross shaft technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of long heating and heat preservation time of steel pipes, low mechanical properties, and low hardness, so as to save materials and improve Performance of heat treatment, effect of improving hardness and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention;

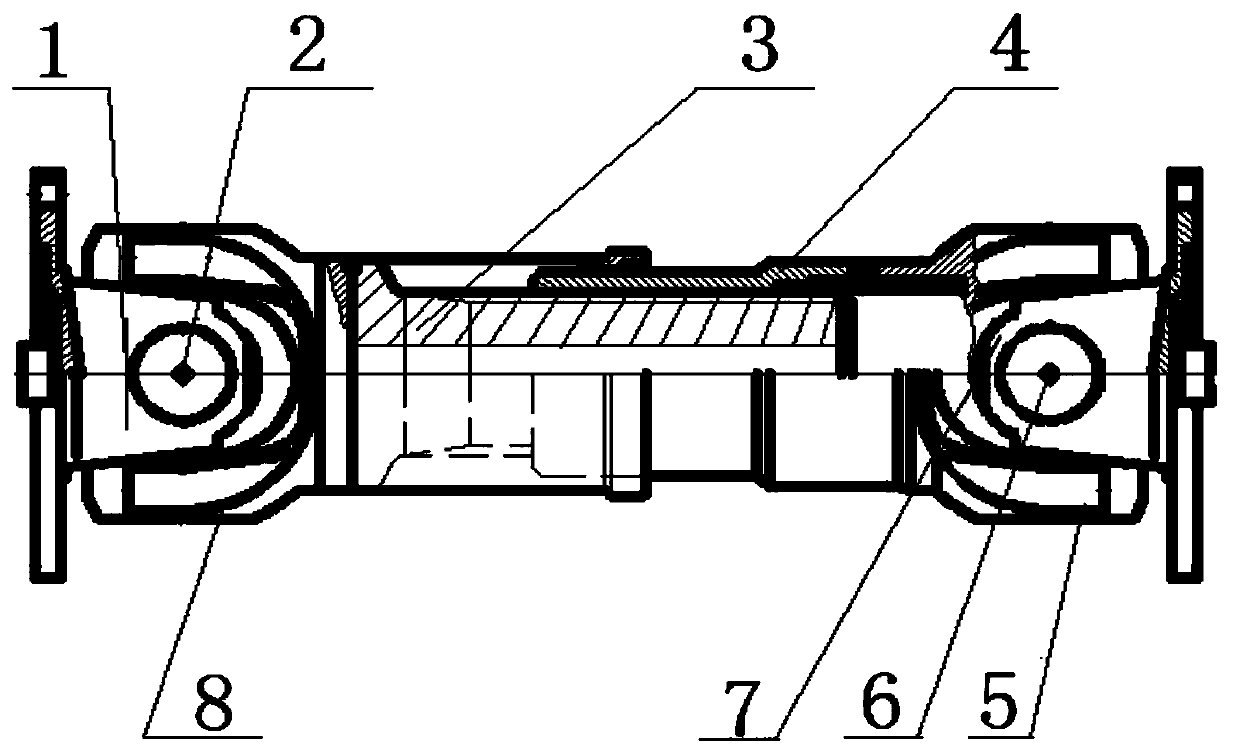

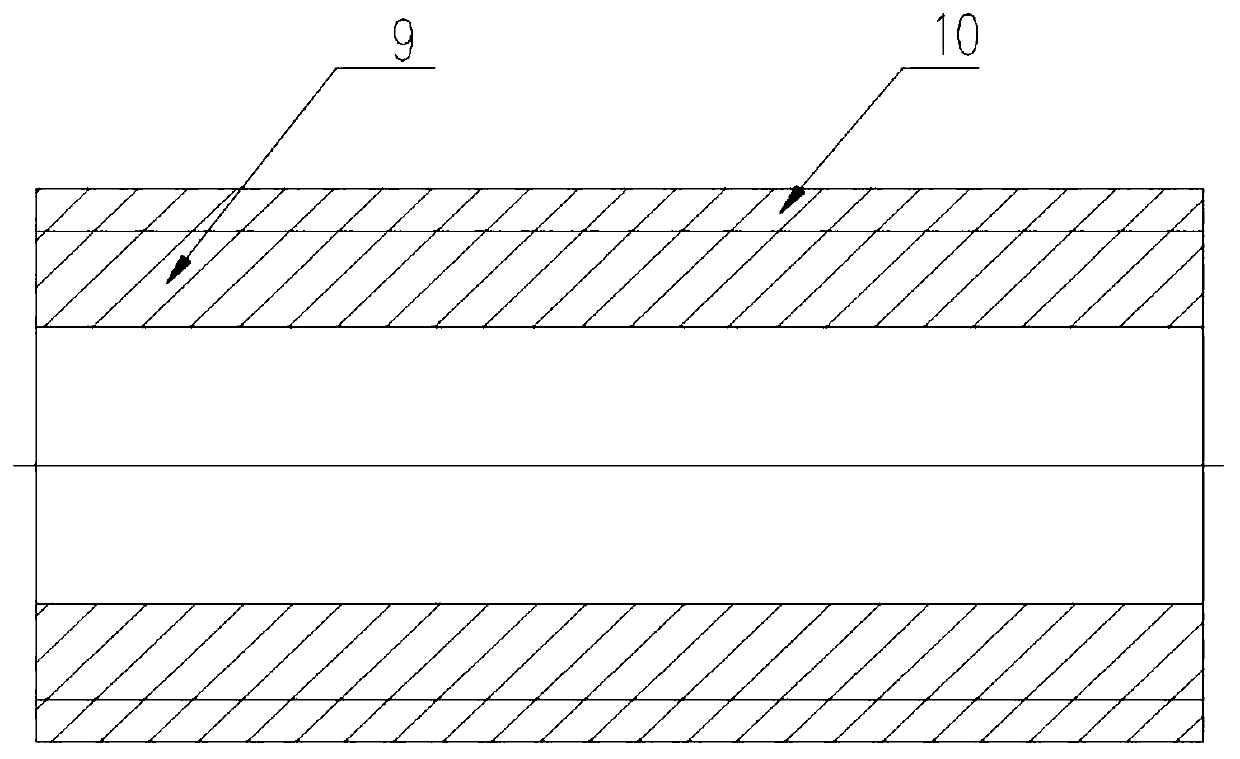

[0039] Such as figure 1 As shown, the preferred embodiment of the present invention, the cross shaft universal coupling with spline pair includes: flange yoke 1, cross shaft assembly 2, splines made of thick-walled seamless metal tubes Shaft 3, spline sleeve 4, welding yoke 5, cross shaft assembly 6, flange yoke 7 and welding yoke 8; one end of flange yoke 1 is fixedly connected to the transmission shaft, and one end is movably connected to the cross shaft assembly 2; One end of the cross shaft assembly 2 is movably connected to the flange fork 1, and one end is fixedly connected to the welding fork 8; one end of the welding fork 8 is movably connected to the cross shaft assembly 2, and one end is fixedly connected to the spline shaft 3; one end of the spline shaft 3 One end of the spline sleeve 4 is fixedly connected to the welding fork 5, one end is mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com