Integrated photoelectrocatalysis-membrane separation fluidized bed reaction device

A technology of fluidized bed reaction and photoelectric catalysis, applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve the problems of difficult separation of powder, high probability of electron-hole recombination, and complex structure of reaction devices and other problems, to achieve the effects of avoiding current damage, high photoelectric catalytic oxidation reaction efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

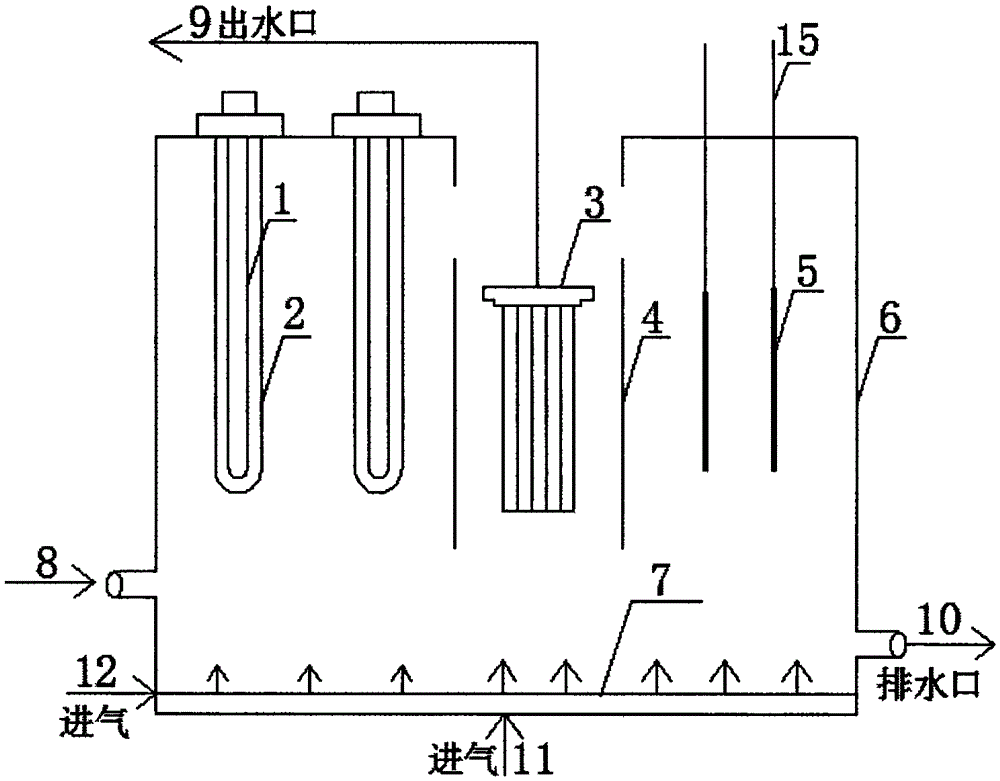

[0037] Such as figure 1 As shown, an integrated photoelectric catalysis-membrane separation fluidized bed reaction device, the bottom of the housing 6 is provided with a water inlet 8, a water outlet 10, air inlets 11, 12, the middle part is provided with an inner housing 4, and the top is provided with a Water outlet 9, an aeration device 7 is installed at the bottom of the housing 6, and a bracket is provided on the top of the housing 6 for installing the ultraviolet light source, the membrane module outlet pipeline and the electrode plate wire 15 to fix the ultraviolet light source, the electrode plate 5 and the membrane module 3 At the position of the reaction device, wherein the ultraviolet light source is arranged on the left (right) part of the housing 6, it is a single light source ultraviolet lamp 1 or a quartz sleeve or a quartz cold trap cover 2 that the single light source ultraviolet lamp 1 and its outer cover have; Plate 5 is arranged on housing 6 right (left) pa...

Embodiment 2

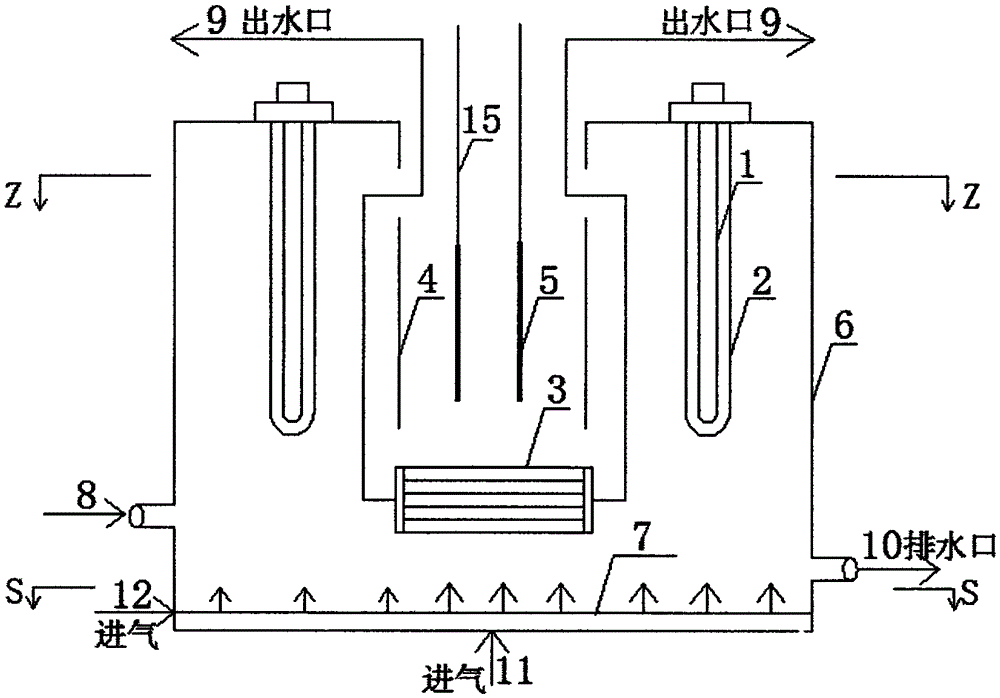

[0042] Such as figure 2 , 4 , shown in 5, a kind of integral photocatalysis-membrane separation fluidized bed reaction device, the bottom of shell 6 is provided with water inlet 8, drain 10, air inlet 11,12, middle part is provided with inner shell 4, top A water outlet 9 is provided, an aeration device 7 is installed at the bottom of the housing 6, and a bracket is provided on the top of the housing 6 for installing the ultraviolet light source, the outlet pipeline of the membrane module and the electrode plate wire 15 to fix the ultraviolet light source, the electrode plate 5 and the membrane The position of the module 3 in the reaction device, the membrane module 3 is installed on the ultraviolet light source, the lower part of the electrode plate 5, and the upper part of the aeration device 7, and the membrane module 3 is a submerged membrane module, preferably a curtain membrane module; the ultraviolet light source is arranged on the housing 6. On the left, right, upper...

Embodiment 3

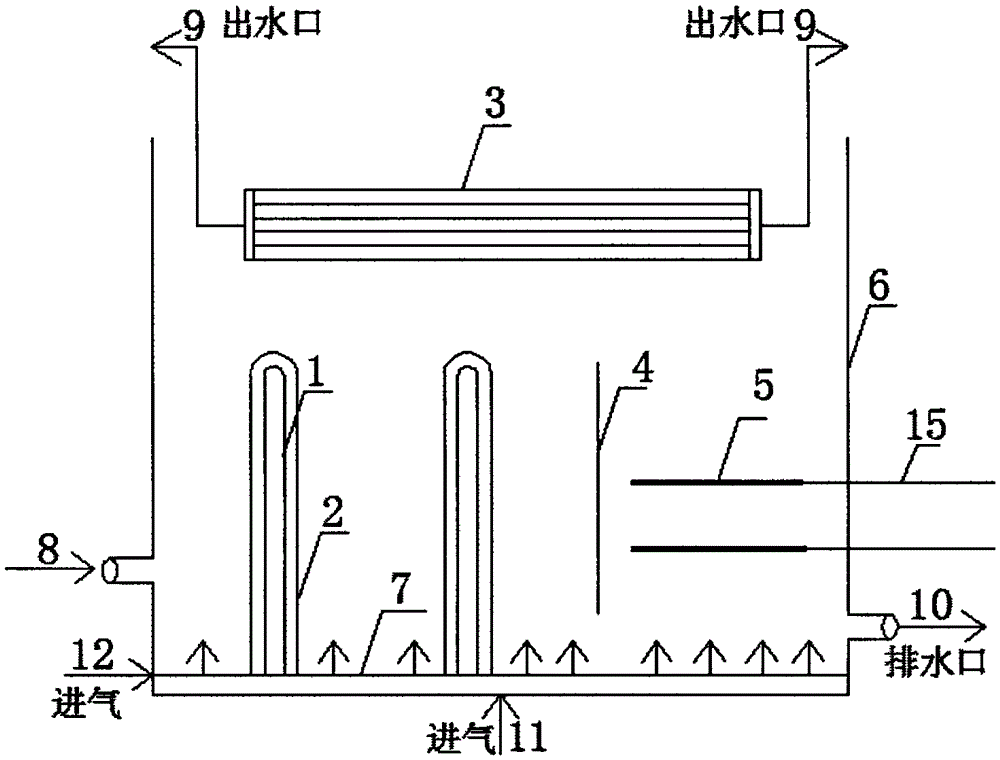

[0046] Such as image 3 As shown, an integrated photoelectric catalysis-membrane separation fluidized bed reaction device, the bottom of the housing 6 is provided with a water inlet 8, a water outlet 10, the top is provided with a water outlet 9, and the bottom of the housing 6 is also equipped with an aeration device 7 , the ultraviolet light source and the electrode plate 5 are respectively arranged on both sides of the housing 6 and located at the lower part thereof, that is, the ultraviolet light source and the electrode plate 5 are distributed left and right or right and left inside the housing 6, and the membrane assembly 3 is arranged between the ultraviolet light source and the electrode plate 5; the membrane module 3 is a submerged membrane module, preferably, a U-shaped membrane module or a curtain membrane module; the ultraviolet light source is an ultraviolet lamp 1 or a quartz sleeve or a quartz cold trap cover 2 for an ultraviolet lamp 1 and its outer cover Elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com