Plunger friction pair of high-pressure seawater axial plunger pump with bionic non-smooth surface

A non-smooth surface, axial piston pump technology, applied in the field of piston friction pair, can solve the problems of easy corrosion, wear, affecting the normal use and service life of the piston pump, failure and other problems, and achieves low cost, high cost performance, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

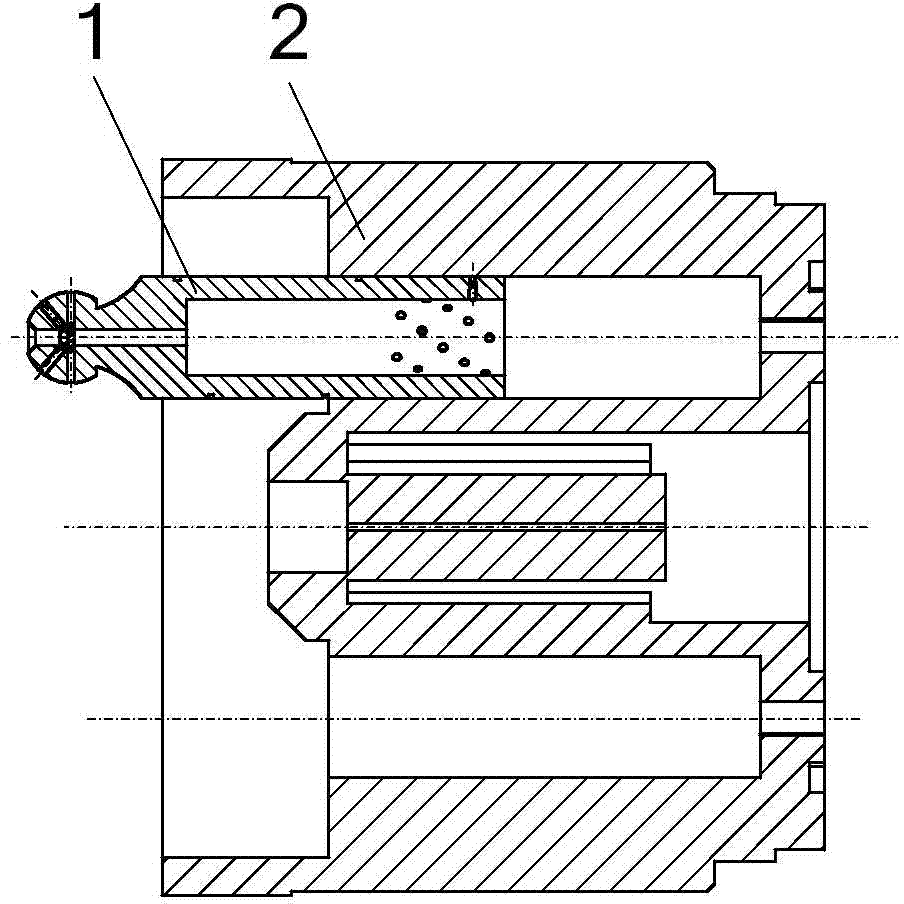

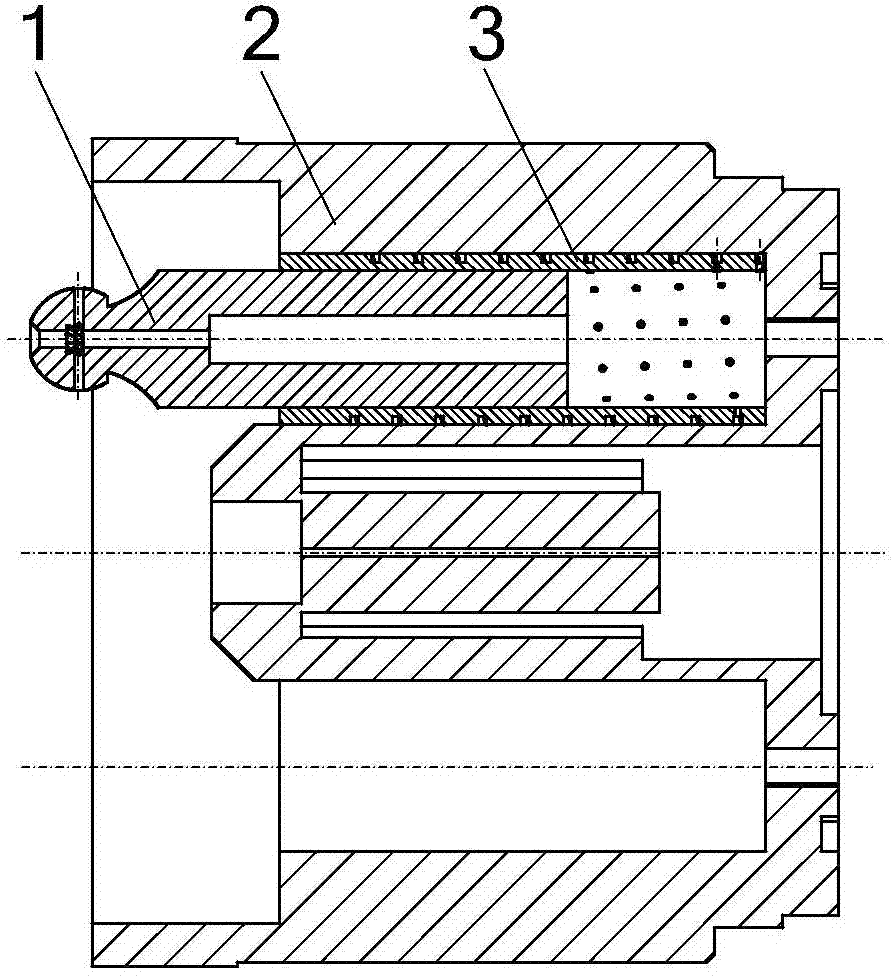

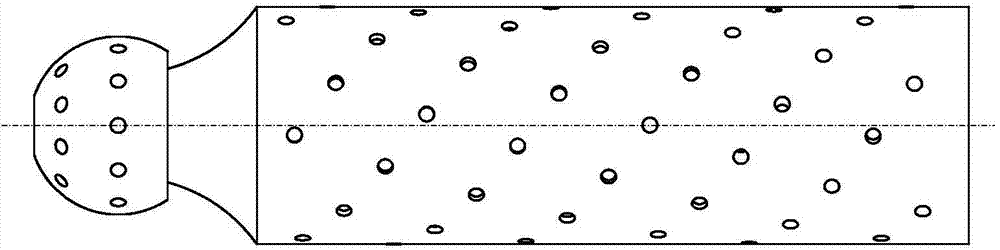

[0025] exist figure 1 , image 3 and Figure 4 In the schematic diagram of the plunger friction pair of the high-pressure seawater axial plunger pump with the bionic non-smooth surface shown, the present invention includes the plunger friction pair composed of the cylinder body and the plunger, and the plunger friction surface of the friction pair is in operation. There are a number of through-hole units connected to the inner cavity of the plunger on the friction surface inside the cylinder, with a diameter of 1.2mm; the rest of the friction surface of the plunger is provided with a number of pit units with a depth of 0.6mm. The opening area on the plunger surface is 1.13mm 2 . The above-mentioned through-hole unit body and the pit unit body are distributed in a helical shape, and the helical pitch is 10 mm. The above-mentioned through-hole unit body and the pit unit body together form a bionic non-smooth surface morphology. There are many kinds of cross-sectional shapes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com