Graphite-like carbon nitride/polyvinylidene fluoride composite material and preparation method thereof

A graphite-type carbon nitride and polyvinylidene fluoride technology, applied in the fields of polyvinylidene fluoride composite materials and their preparation, high-performance polymer composite materials and their preparation fields, can solve the problem of low friction coefficient wear resistance, low density, low energy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

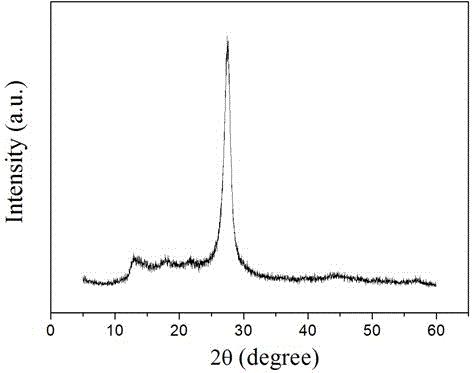

[0039] Weigh 5g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1 .

[0040] Weigh the yellow g-C prepared above 3 N 4 Powder 2g, added volume is g-C 3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was dispersed in an ultrasonic vibrator for 30 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent γ-aminopropyltriethoxysilane with 2% powder mass, then place the mixed solution with coupling agent in an oven and dry for 20 hours at a temperature of 80°C, and dry the alcohol to obtain a dispersion And surface treated g-C 3 N 4 powder raw material.

[0041] The polyvin...

Embodiment 2

[0045] Weigh 3g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1 .

[0046] Weigh the yellow g-C prepared above 3 N 4 Powder 1g, added volume is g-C 3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was placed in an ultrasonic vibrator to disperse for 40 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent γ-aminopropyltriethoxysilane with 2% powder mass, then put the mixed solution with coupling agent in an oven and dry for 10 hours at a temperature of 80°C, and dry the alcohol to obtain a dispersion And surface treated g-C 3 N 4 powder raw material.

[0047] The ...

Embodiment 3

[0051] Weigh 2g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1

[0052] Weigh the yellow g-C prepared above 3 N 4 Powder 0.5g, added volume is g-C 3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was placed in an ultrasonic vibrator to disperse for 40 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent γ-aminopropyltriethoxysilane with 2% powder mass, then put the mixed solution with coupling agent in an oven and dry for 10 hours at a temperature of 80°C, and dry the alcohol to obtain a dispersion And surface treated g-C 3 N 4 powder raw material.

[0053] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com