High-silicon aluminum alloy cylinder sleeve material and fabrication method thereof

A technology of high-silicon aluminum alloy and manufacturing method, which is applied in the field of high-silicon aluminum alloy cylinder liner materials and its preparation, and can solve problems such as poor product performance uniformity, high brittleness of high-silicon aluminum alloy, and influence on material and product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

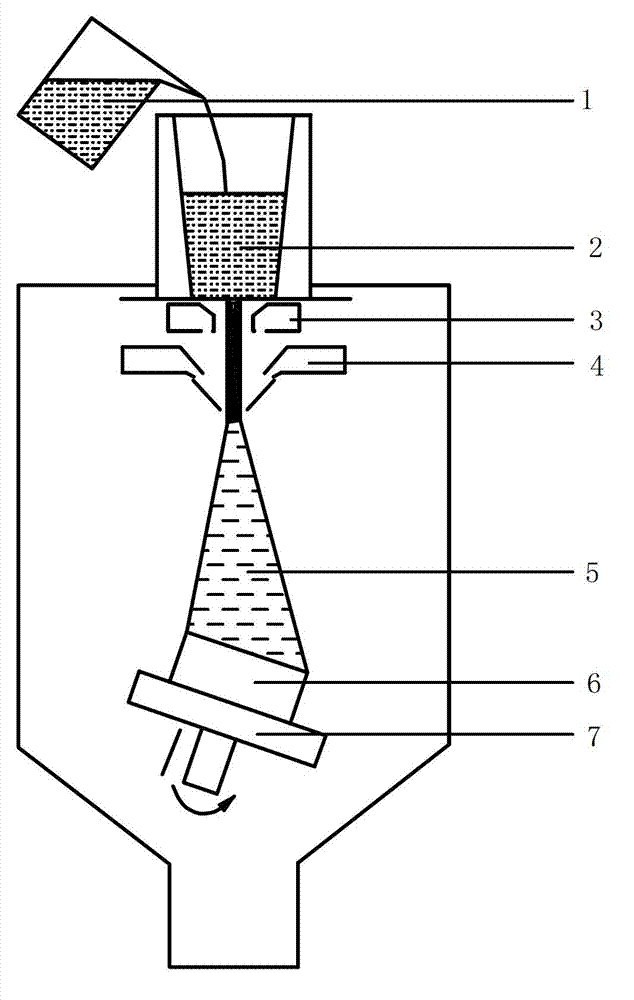

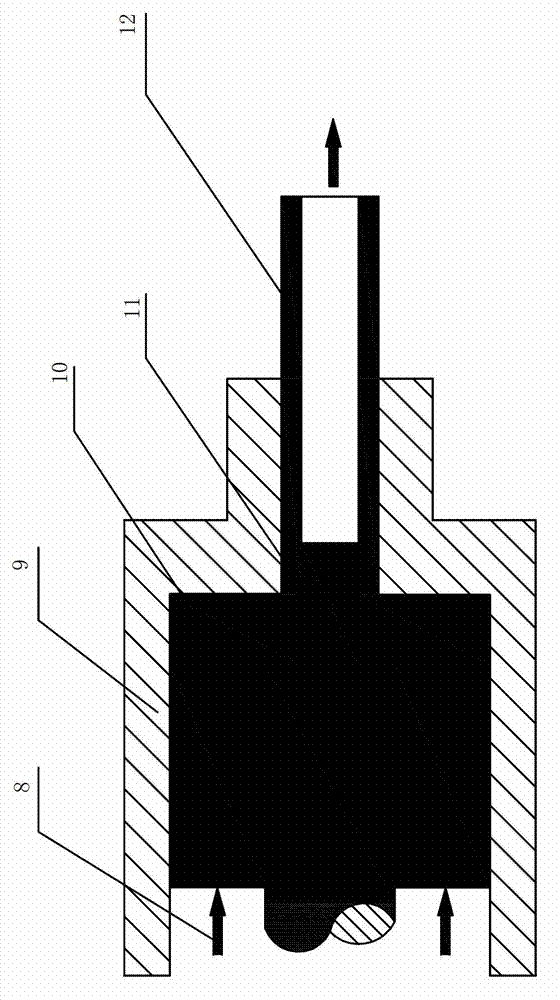

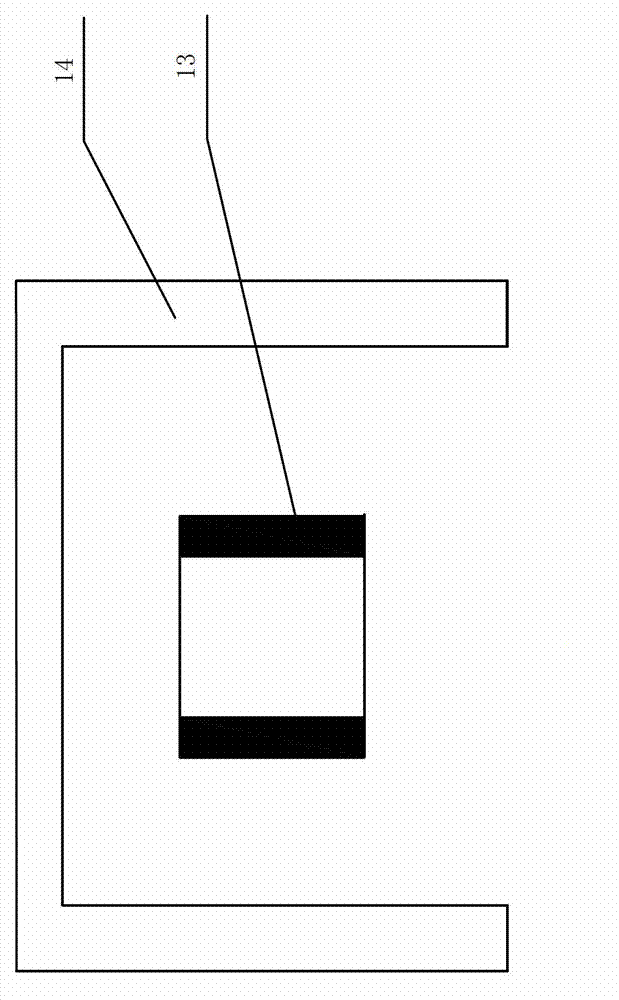

[0136] Preparation method of high silicon aluminum alloy cylinder liner:

[0137] ① Composition design and precise batching: carry out precise batching according to the composition formula of the alloy of the present invention. In the batching method, the high melting point alloy elements such as silicon, iron, nickel, manganese, copper, vanadium, etc., are prepared by the method of master alloy, so that these high melting point alloy elements can be added to the low melting point aluminum, namely The batching is carried out in the form of furnace charge of Al-40%Si, Al-30%Fe, Al-20%Ni, Al-50%Cu, Al-15%Mn, Al-15%V master alloy. The melting point of magnesium is close to the melting point of aluminum, and the batching is carried out in the form of pure metal charge. After batching with the charge of master alloy, if the amount of aluminum is insufficient, it will be supplemented with the charge of pure aluminum.

[0138] ②Smelting, covering and refining:

[0139] It is smelt...

Embodiment 1、 Embodiment 2 and Embodiment 3

[0201] The formulations of the three examples are shown in Table 1.

[0202] Table 1 each embodiment chemical composition (wt%)

[0203]

[0204] Take Example 2 as an example to do batching calculation:

[0205] 1) The chemical composition of embodiment 2 is as follows by weight ratio:

[0206] Si: 21.0%; Fe: 4.0%; Ni: 3.0%; Cu: 2.5%; Mg: 0.6%; Mn: 0.8%; V: 0.2%;

[0207] 2) Calculate the ingredients according to the burden weight of 120 kg:

[0208]Then the weight of each alloying element needs to be:

[0209] Si: 25.2 kg; Fe: 4.8 kg; Ni: 3.6 kg; Cu: 3.0 kg; Mg: 0.72 kg; Mn: 0.96 kg; V: 0.24 kg;

[0210] The weight of Al is: 120 kg - the sum of the weights of the above alloy elements (38.52 kg), which is 81.48 kg.

[0211] 3) Because silicon, iron, nickel, manganese, copper, vanadium and other alloy elements are added in the form of intermediate alloy charge. Therefore, it must be converted into the added weight of the master alloy. but:

[0212] ① To add 25.2 kg o...

Embodiment 2

[0240] Table 4 Example 2 Tribological performance characteristics

[0241]

[0242] Note: The tribological performance test is tested on the RFT-Ⅲ reciprocating friction and wear testing machine.

[0243] 1) The loading pressure is 800N, the loading time is 2.5 hours, the reciprocating speed is 0.5mm / s, the stroke is 50mm, and the lubricating oil is RP4652D oil;

[0244] 2) 38CrMoAl steel bar is the current engine cylinder liner material, the thickness of the nitrided layer is 0.3-0.5mm, and the hardness is greater than or equal to 76HRA; the chrome-plated cast iron bolt is the current engine piston ring material, the coating thickness is 0.08-0.12mm, and the hardness is HRC63-65; The hardness of the silicon-aluminum alloy strip matrix is HBW185-200, the hardness of silicon particles is HV1050, and the hardness of the iron-nickel compound phase is HV680-980.

[0245] Table 5 Example 2 mechanical performance characteristics

[0246]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com