Carbon fiber reinforced polymer-based self-lubricating material and preparation method thereof

A lubricating material and polymer technology, which is applied in the field of carbon fiber reinforced polymer-based self-lubricating materials and its preparation, can solve the problems of low friction reduction and wear resistance, short service life, poor lubrication performance, etc., and achieve improved friction reduction and wear resistance ability, low wear rate, and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process is as follows:

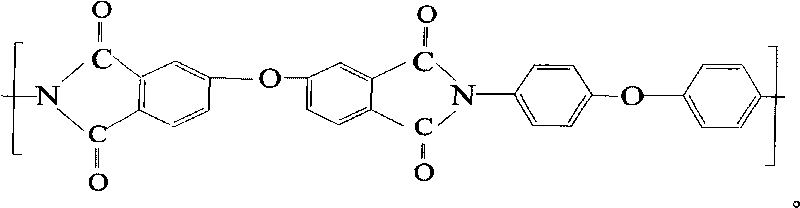

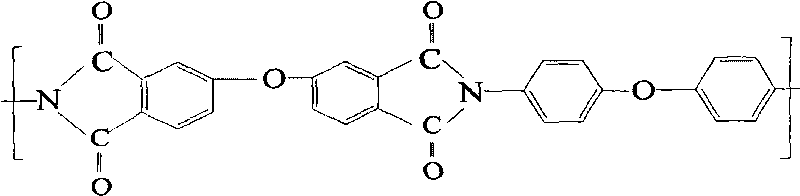

[0025] (1) Select polyimide as the resin matrix, mass fraction: 30%;

[0026] (2) Use chopped carbon fiber as reinforcement, mass fraction: 10%;

[0027] (3) Molybdenum disulfide and antimony trioxide are selected as lubricating additives, and the mass fractions are: 40% and 20% respectively.

[0028] (4) First mix polyimide, molybdenum disulfide and antimony trioxide uniformly, then add chopped carbon fiber, and fully mix uniformly;

[0029] (5) Pour the mixed molding materials into the mold and hot press molding, the molding temperature is 360°C, the pressure is 35MPa, heat preservation and pressure holding for 40 minutes, and natural cooling.

Embodiment 2

[0031] The preparation process is as follows:

[0032] (1) Select polyimide as the resin matrix, mass fraction: 40%;

[0033] (2) Use chopped carbon fiber as reinforcement, mass fraction: 20%;

[0034] (3) Molybdenum disulfide and antimony trioxide are selected as lubricating additives, and the mass fractions are respectively: 30%, 10%;

[0035] (4) First mix polyimide, molybdenum disulfide and antimony trioxide uniformly, then add chopped carbon fiber, and fully mix uniformly;

[0036] (5) Pour the mixed molding material into the mold and hot press molding, the molding temperature is 380°C, the pressure is 38MPa, heat preservation and pressure holding for 50 minutes, and natural cooling.

Embodiment 3

[0038] The preparation process is as follows:

[0039] (1) Select polyimide as the resin matrix, mass fraction: 50%;

[0040] (2) Use chopped carbon fiber as reinforcement, mass fraction: 10%;

[0041] (3) Molybdenum disulfide and antimony trioxide are selected as lubricating additives, and the mass fractions are respectively: 30%, 10%;

[0042] (4) First mix polyimide, molybdenum disulfide and antimony trioxide uniformly, then add chopped carbon fiber, and fully mix uniformly;

[0043] (5) Pour the mixed mold material into the mold for hot press molding, the molding temperature is 370°C, the pressure is 40MPa, heat preservation and pressure holding for 40 minutes, and natural cooling;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com