High-temperature plasma waste gasification and cracking furnace

A technology of gasification cracking furnace and high-temperature plasma, which is applied in the direction of gasification process, manufacture of combustible gas, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

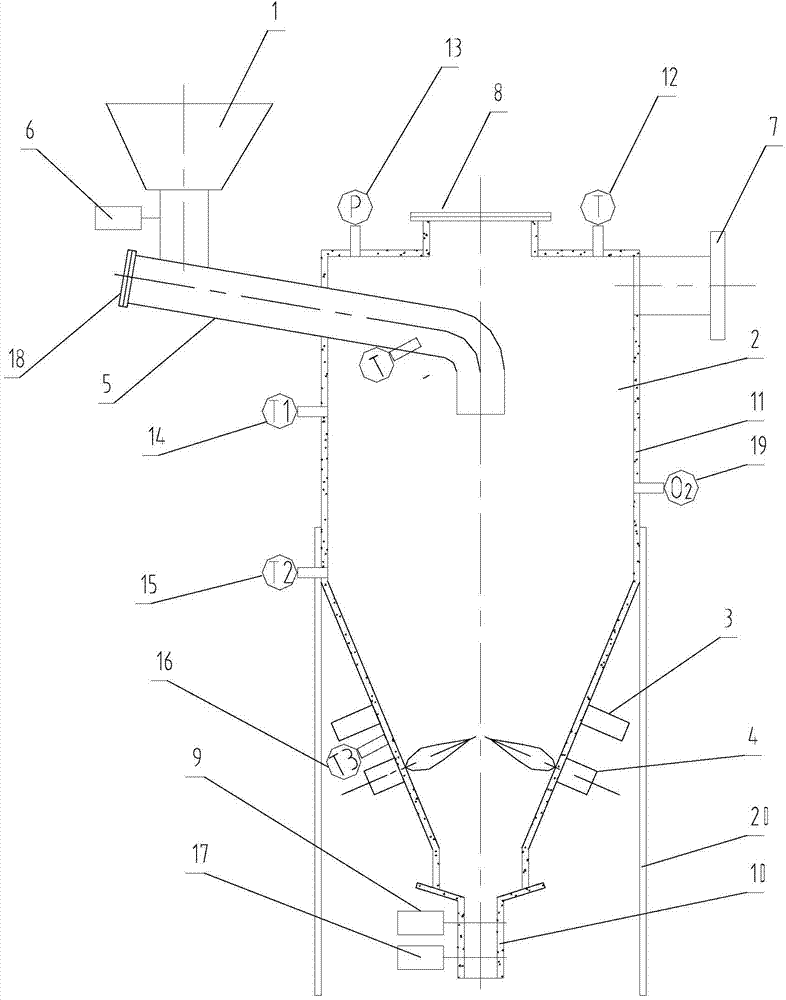

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

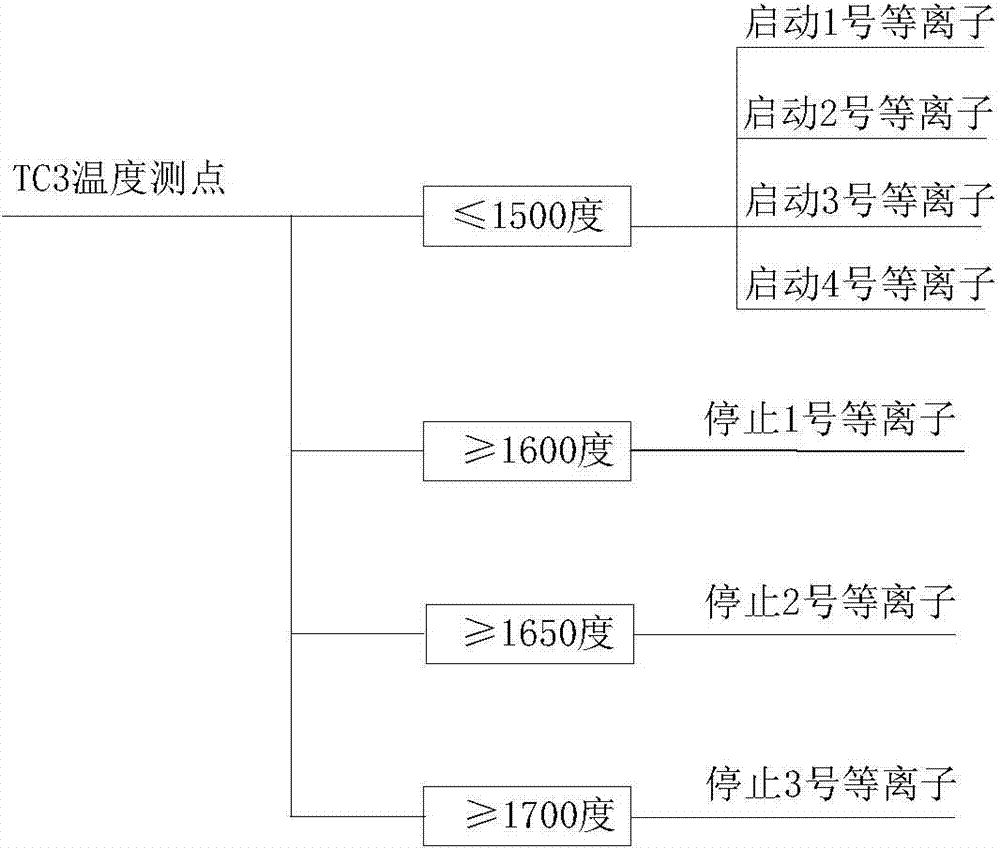

[0027] like figure 1 As shown, a high-temperature plasma garbage gasification cracking furnace includes a control cabinet, a furnace body 2, a feeding system arranged on one side of the furnace body 2, a blanking system arranged at the bottom of the furnace body, and a Gas outlet 7; the lower end of the furnace body is provided with a group of plasma generators 4, and a group of rotating nozzles 3 are arranged at the upper end of the ion generator 4 and form a certain angle with the vertical line of the furnace body center. Temperature thermocouple and oxygen detector 19. The control cabinet is respectively connected with the temperature thermocouple, the oxygen detector 19, the plasma generator 4, the blanking system and the rotary nozzle 3, and the control cabinet controls the rotary nozzle 3 and the plasma generator 4 through an internal program.

[0028] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com