Automatic punching machine for bar products

A punching machine and product technology, applied in the direction of driving device, boring/drilling, drilling/drilling equipment, etc., can solve problems such as damage to polygonal bar products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

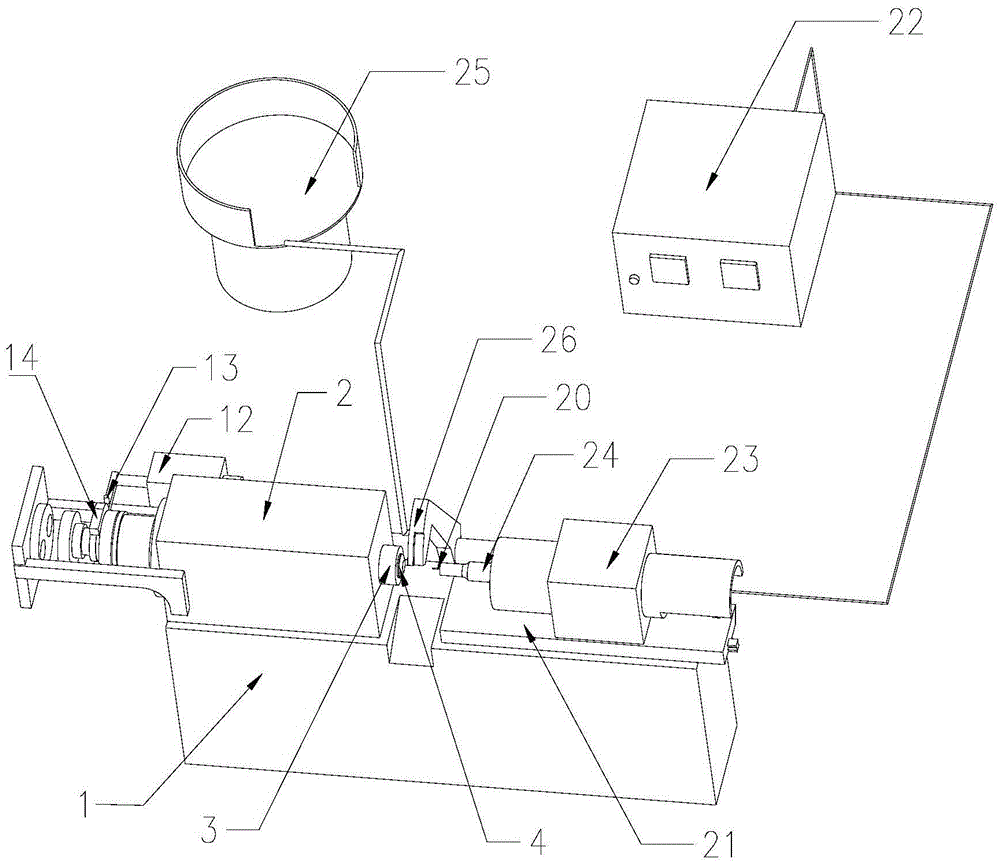

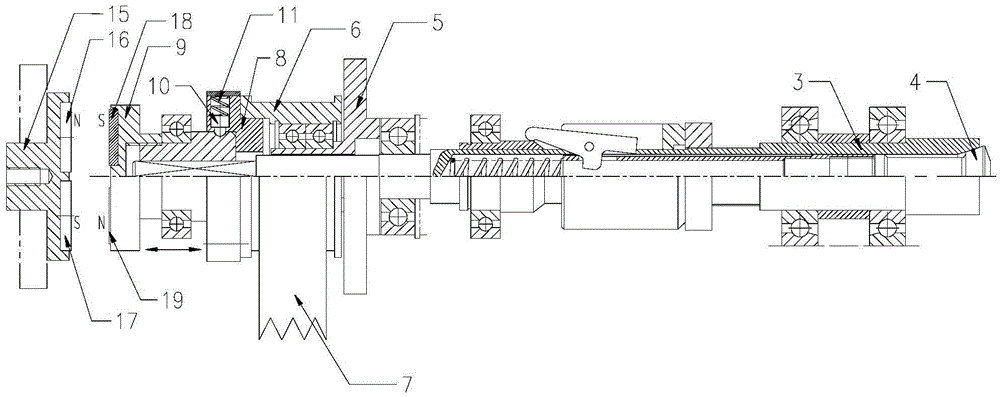

[0017] Embodiment 1: As shown in the figure, an automatic punching machine for bar products includes a frame 1, a controller, a feeding device, a main shaft 3 boxes and a punching device, and the main shaft 3 boxes include a box fixedly arranged on the frame 1 on the box body 2, the main shaft 3, the rotary drive device, the collet 4 and the telescopic drive mechanism, the main shaft 3 is located in the box body 2 and its front end extends out of the box body 2, and the collet chuck 4 is installed in the front end of the main shaft 3 The telescopic drive mechanism is used to drive the collet 4 to extend out of the main shaft 3 or retract into the main shaft 3. The controller is connected with the feeding device, the telescopic drive mechanism and the punching device respectively. The rotary drive device includes a mounting seat 5, a pulley 6, The pulley driving mechanism 7, the first clutch 8, the second clutch 9, the toggle mechanism and the positioning limit mechanism, the to...

Embodiment 2

[0023] Embodiment 2: As shown in the figure, an automatic punching machine for bar products includes a frame 1, a controller, a feeding device, a main shaft 3 boxes and a punching device, and the main shaft 3 boxes include a frame fixed on the frame 1 on the box body 2, the main shaft 3, the rotary drive device, the collet 4 and the telescopic drive mechanism, the main shaft 3 is located in the box body 2 and its front end extends out of the box body 2, and the collet chuck 4 is installed in the front end of the main shaft 3 The telescopic drive mechanism is used to drive the collet 4 to extend out of the main shaft 3 or retract into the main shaft 3. The controller is connected with the feeding device, the telescopic drive mechanism and the punching device respectively. The rotary drive device includes a mounting seat 5, a pulley 6, The pulley driving mechanism 7, the first clutch 8, the second clutch 9, the toggle mechanism and the positioning limit mechanism, the toggle mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com