Straightness detection method of cylindrical bar and application system of straightness detection method

A detection method, a cylindrical technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low accuracy, low efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is used for detecting cylindrical cemented carbide rods, especially rods with a diameter ranging from 2.0 to 20.0 mm and a length ranging from 200 to 400 mm. For the convenience of description, the "cylindrical cemented carbide rod" is simply referred to as "rod" hereinafter.

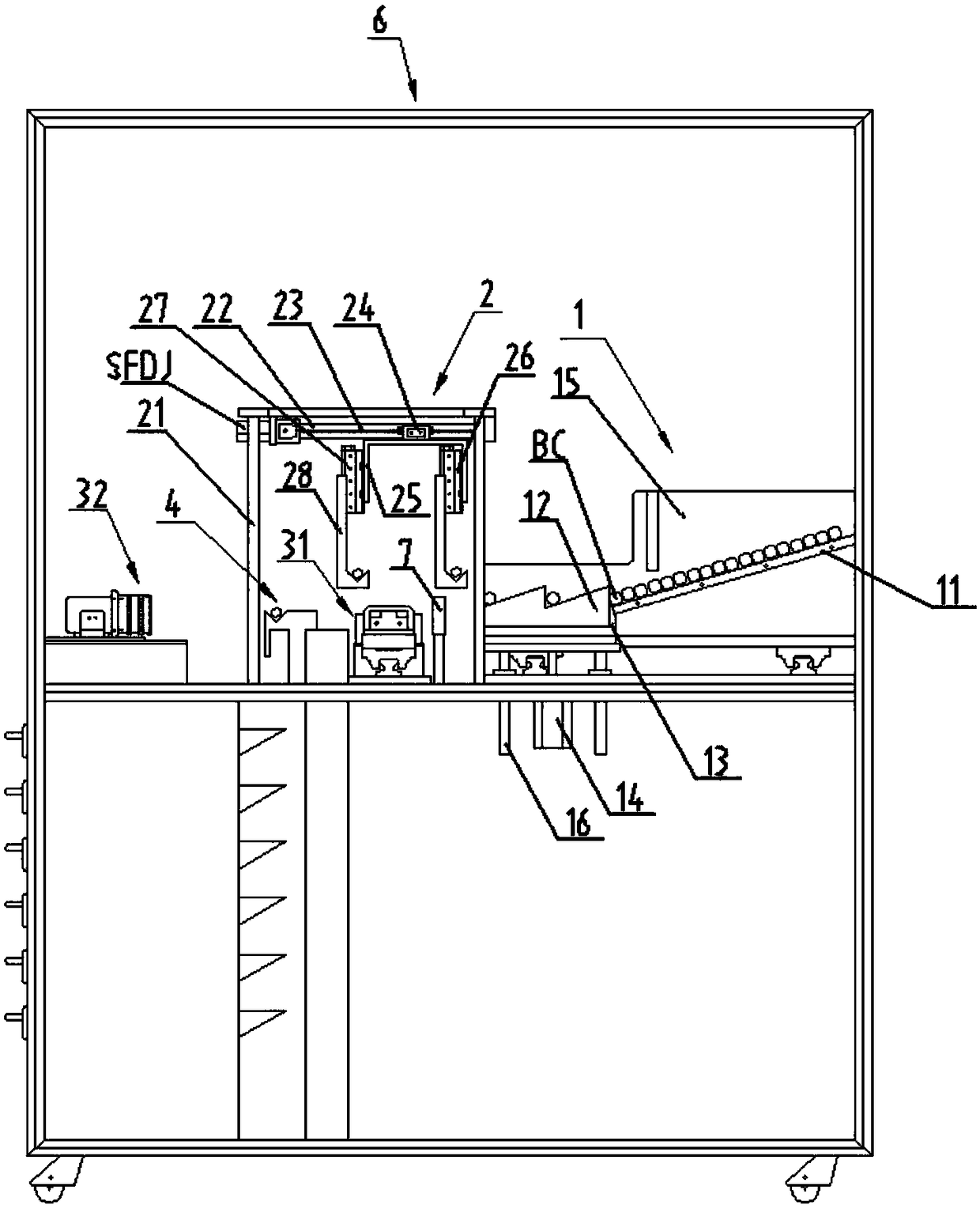

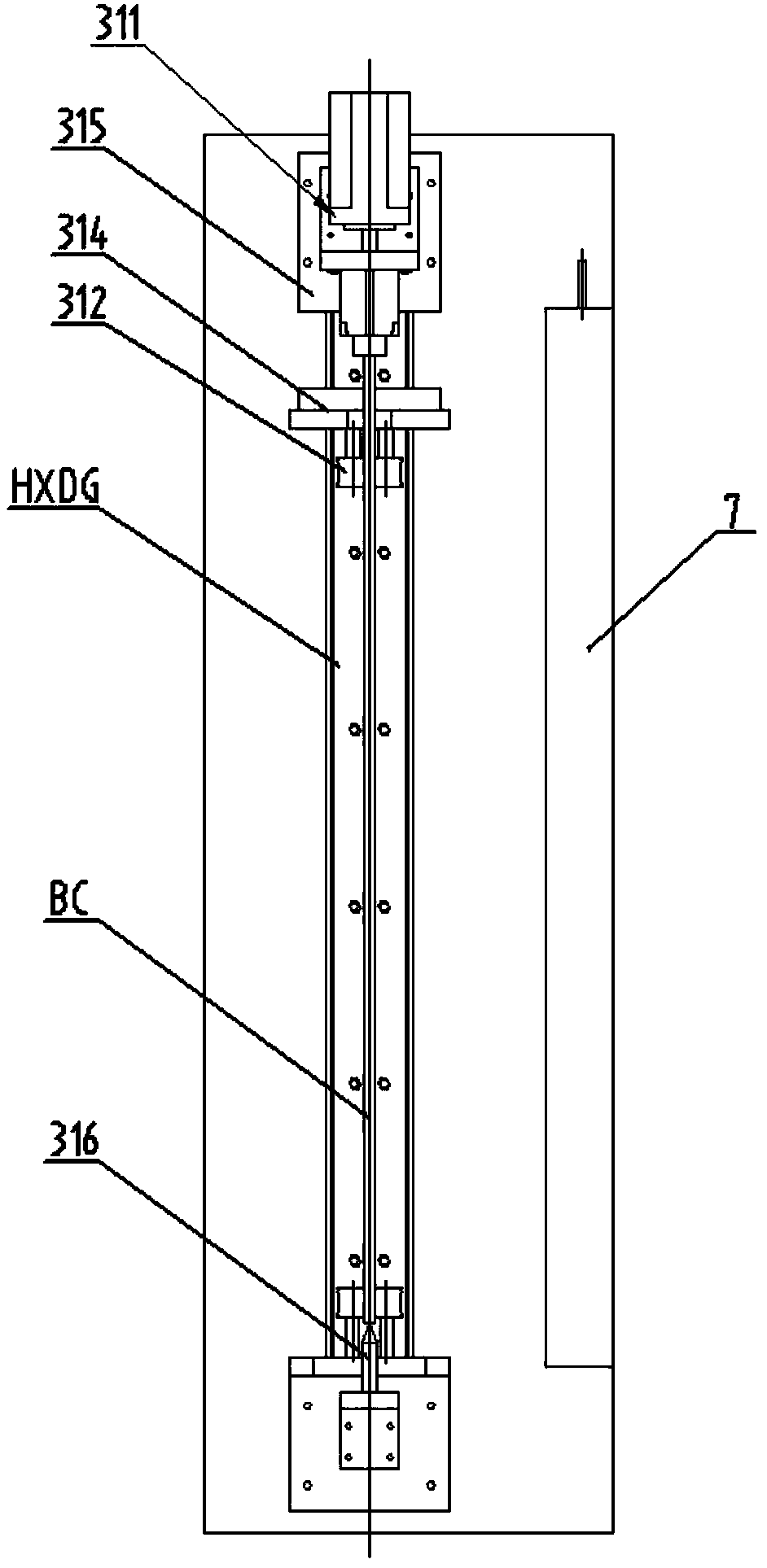

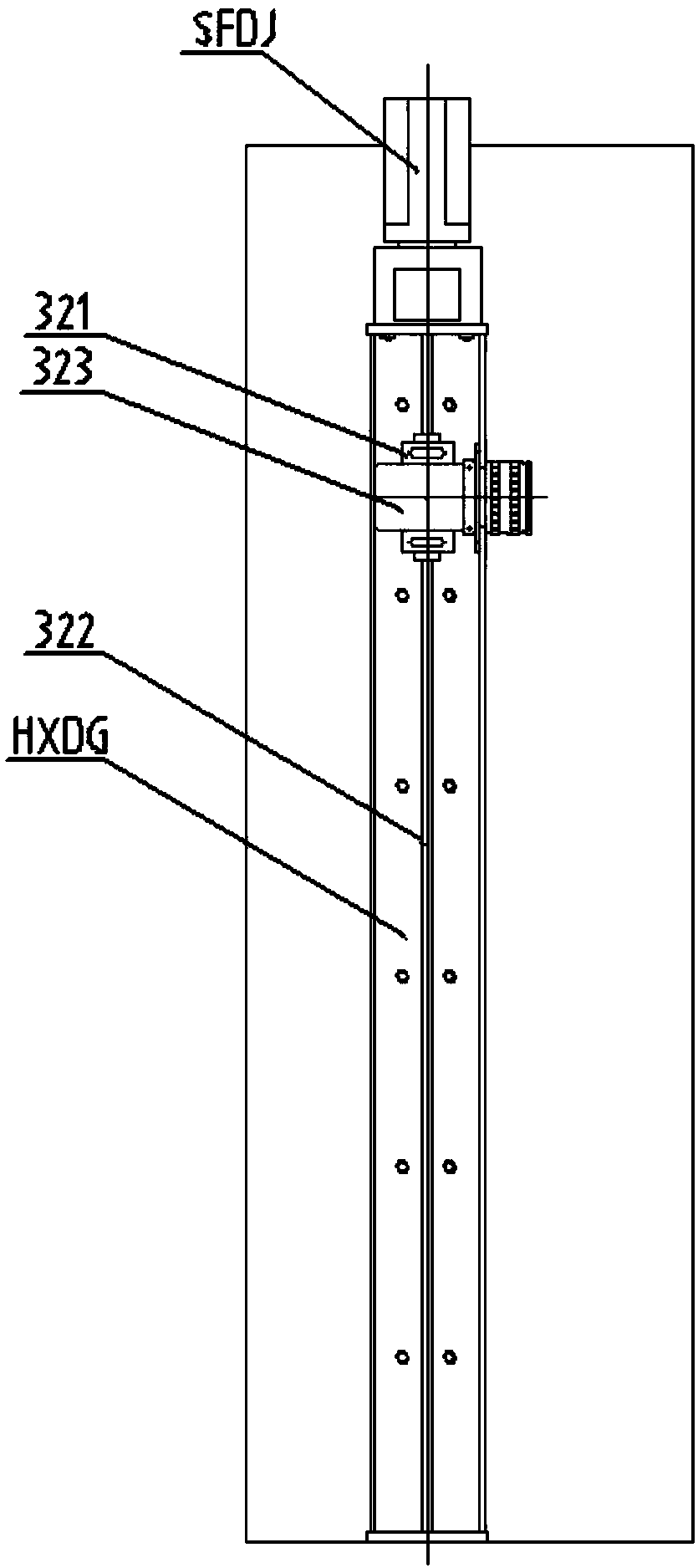

[0027] Such as figure 1 As shown, the whole system includes a fuselage 6 with a frame structure and a feeding device 1 , a transfer device 2 , a detection device, and a sorting device 4 installed on the fuselage. The detection device includes two sub-sections, the first sub-section is a bar supporting and rotating device 31 , and the second sub-section is a bar straightness scanning device 32 . The feeding device, the detection device and the sorting device are arranged on the longitudinal center plane.

[0028] Such as figure 1 As shown, the feeding device 1 includes a slideway 11 , a fixed stepped plate 12 , a lifting stepped plate 13 , a jacking device 14 , and a side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com