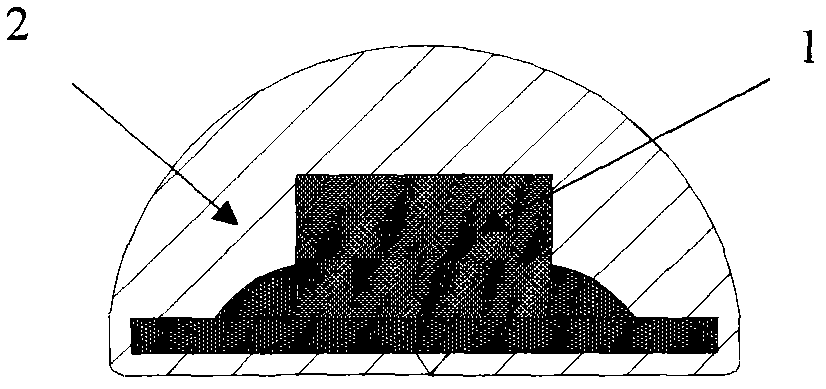

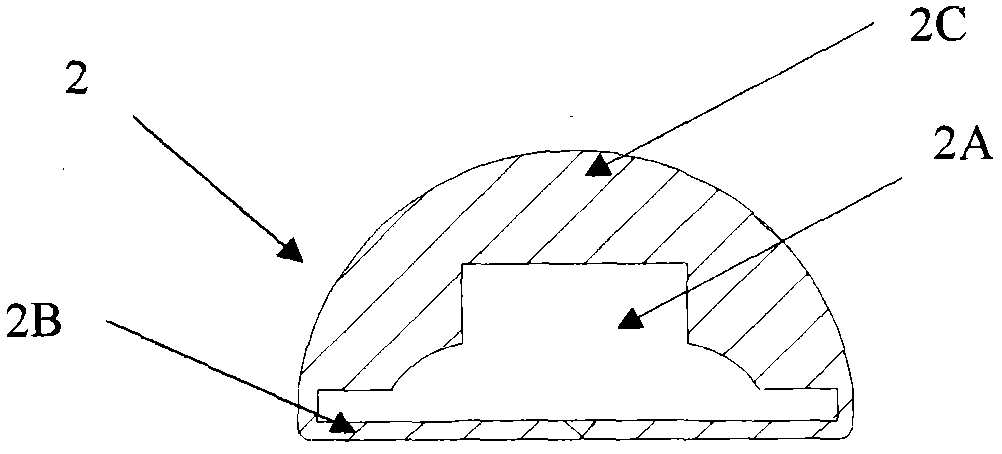

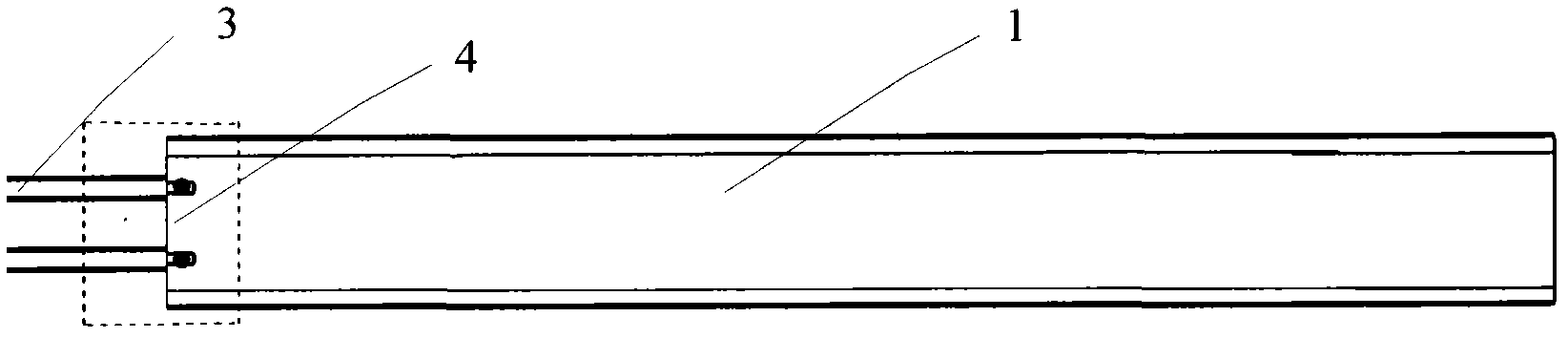

Light-emitting diode lamp bar with fully waterproof glue pouring structure and manufacturing method thereof

A technology for LED light strips and glue filling, which is used in gas/waterproof devices, parts of lighting devices, semiconductor devices of light-emitting components, etc. It can solve the problems of large production space, low waterproof level, cracking, etc. The effect of improved life and reliability, good waterproof sealing performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of a method for sealing an LED light bar according to the present invention will be described in more detail below.

[0025] However, those skilled in the art should understand that the following are only examples and descriptions of some preferred implementations, and other similar or equivalent implementations can also be used to implement the present invention.

[0026] In the present invention, "LED light strip" should be understood in a broad sense, including not only LED flexible light strips, that is, LED light strips installed on flexible circuit boards (FPC), but also LED hard light strips, that is, on LED light strips mounted on PCB circuit boards (also known as "rigid boards" or "rigid circuit boards" in the industry); not only light strips with LEDs mounted on single-sided circuit boards, but also double-sided circuit boards or multi-layer circuit boards LED strips, etc. These all belong to the scope of the present invention.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com