Low-pressure core filling preparation technology of copper-clad aluminum composite material

A composite material and preparation technology, applied to heat exchange equipment, rotors, cylinders, etc., can solve problems such as complex procedures, high production costs, and low product quality, and achieve simple process, low production costs, and utilization of molten aluminum high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

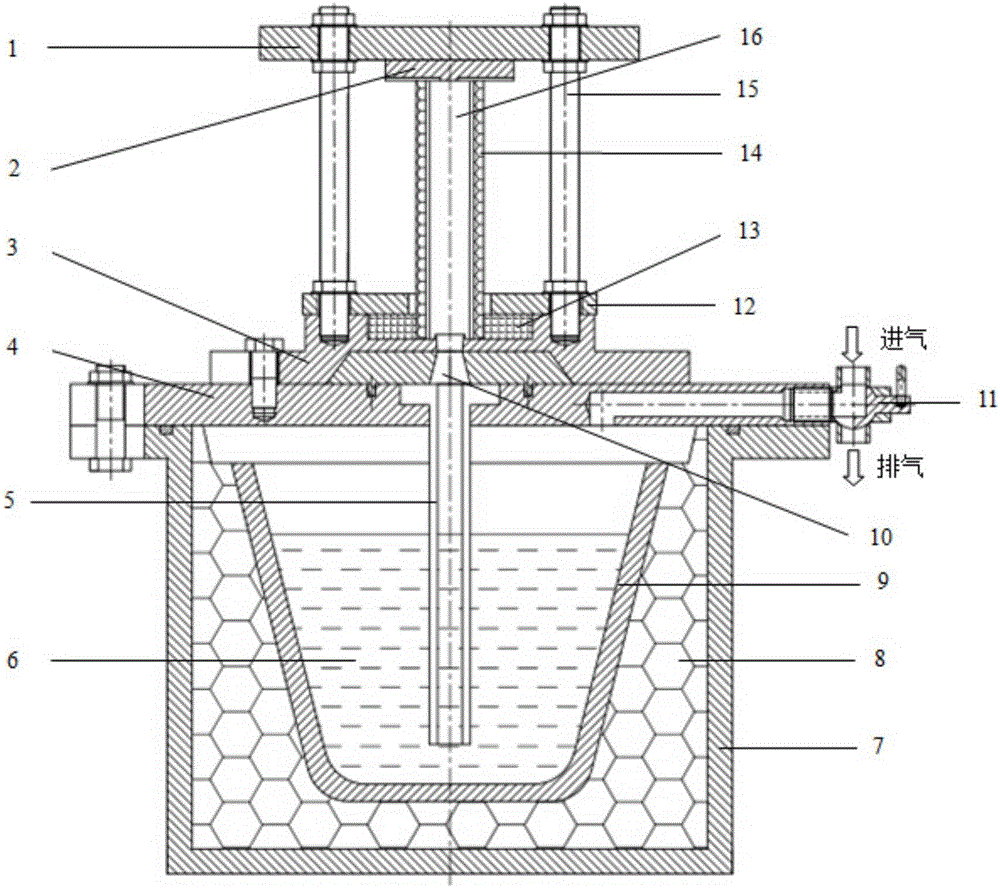

Image

Examples

Embodiment 1

[0027] Step 1. Degrease and descale the inner wall of the copper tube, prepare a supersaturated potassium fluorozirconate solution and heat it to 95°C, pour it into the copper tube and let it cool for 6 minutes before pouring it out, and then put the copper tube into the drying in a drying oven;

[0028] In this process, it is necessary to control the standing time. If the standing time is too short, the deposited potassium fluorozirconate film will be uneven and incomplete, and the anti-oxidation effect will be poor; if the standing time is too long, the potassium fluorozirconate film will be too thick. Entering the copper tube, potassium fluorozirconate generates a large amount of gas when it is thermally decomposed, which may cause pore defects.

[0029] Step 2: put industrial pure aluminum into a crucible resistance furnace and melt it, the melting temperature is 740°C; put the copper tube into the resistance furnace for preheating, and the preheating temperature is 450°C....

Embodiment 2

[0038] Step 1. Degrease and descale the inner wall of the copper tube, prepare a supersaturated potassium fluorozirconate solution and heat it to 95°C, pour it into the copper tube and let it cool for 3 minutes before pouring it out, and then put the copper tube into the drying in a drying oven;

[0039] Step 2: Put industrial pure aluminum into a crucible resistance furnace and melt it, the melting temperature is 780°C; put the copper tube into the resistance furnace for preheating, and the preheating temperature is 300°C.

[0040] Step 3: Put the crucible into the low-pressure core filling machine, and connect the preheated copper tube with the low-pressure core filling machine through the asbestos sleeve insulation, and seal it.

[0041] Step 4: Open the three-way valve to fill the core with air at a rate of 300ml / min.

[0042] Step 5. Pressurize to 0.8MPa and hold the pressure until the aluminum liquid in the copper tube is completely solidified, and the holding time is 2...

Embodiment 3

[0045] Step 1. Degrease and descale the inner wall of the copper tube, prepare a supersaturated potassium fluorozirconate solution and heat it to 95°C, pour it into the copper tube and let it cool for 4 minutes before pouring it out, and then put the copper tube into the drying in a drying oven;

[0046] Step 2: put industrial pure aluminum into a crucible resistance furnace and melt it, the melting temperature is 720°C; put the copper tube into the resistance furnace for preheating, and the preheating temperature is 200°C.

[0047] Step 3: Put the crucible into the low-pressure core filling machine, and connect the preheated copper tube with the low-pressure core filling machine through the asbestos sleeve insulation, and seal it.

[0048] Step 4: Open the three-way valve to fill the core with argon gas at a rate of 450ml / min.

[0049] Step 5. Pressurize to 0.5MPa and hold the pressure until the aluminum liquid in the copper tube is completely solidified, and the holding tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com