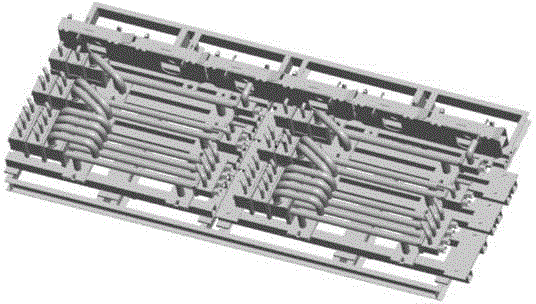

Multifunctional bar graded temperature control rolling and controlled cooling equipment

A temperature-controlled rolling, multi-functional technology, used in metal rolling, temperature control, metal rolling, etc., can solve the problems of small coverage, disappearance of steel grades and specifications, and large temperature difference between sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

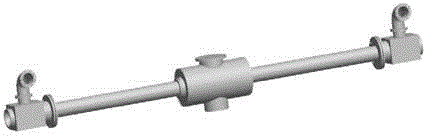

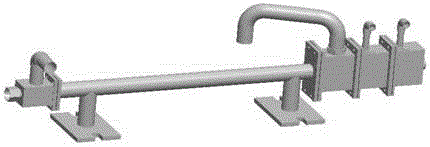

[0041] According to the steel type and specification, the electric push rod is used to move the trolley assembly, and the cooling line of the corresponding specification is aligned with the rolling center line; Set the nozzle water pressure and water flow according to the material specifications and the application of the cooler. Control the overall cooling water temperature to 25-32°C and water pressure to 1.5-2.0MPa.

[0042] A Cooling section choose A 1 、A 3 , the type of cooler is ZFX1, the flow rate is 150m 3 / h, pressure 1.8MPa;

[0043] C Cooling section choose C 1 、C 6 , the type of cooler is DX1, the flow rate is 200m 3 / h, pressure 1.5MPa.

[0044] The temperature curve of the graded controlled rolling process is as follows: Figure 7 As shown, the temperature curve of the staged and controlled cooling process after rolling is as follows Figure 8 shown. Example 2:

Embodiment 2

[0045] According to the steel type and specification, the electric push rod is used to move the trolley assembly, and the cooling line of the corresponding specification is aligned with the rolling center line; Set the nozzle water pressure and water flow according to the material specifications and the application of the cooler. Control the overall cooling water temperature to 25-32°C and water pressure to 1.5-2.0MPa.

[0046] A Cooling section choose A 1 、A 3 , the type of cooler is ZFX2, the flow rate is 200m 3 / h, pressure 1.5MPa;

[0047] B Cooling section choose B 3 , B 4 , flow 250m 3 / h, pressure 1.5MPa;

[0048] C Cooling section choose C 3 、C 8 , the type of cooler is DX3, the flow rate is 300m 3 / h, pressure 1.5MPa.

Embodiment 3

[0050] According to the steel type and specification, the electric push rod is used to move the trolley assembly, and the cooling line of the corresponding specification is aligned with the rolling center line; Set the nozzle water pressure and water flow according to the material specifications and the application of the cooler. Control the overall cooling water temperature to 25-32°C and water pressure to 1.5-2.0MPa.

[0051] A Cooling section choose A 1 、A 2 、A 3 , the type of cooler is ZFX2, the flow rate is 300m 3 / h, pressure 1.5MPa;

[0052] B Cooling section choose B 3 , B 4 , flow 300m 3 / h, pressure 1.5MP a ;

[0053] C Cooling section choose C 4 、C 5 , the type of cooler is DX5, the flow rate is 350m 3 / h, pressure 1.4MPa.

[0054] D Cooling section choose D 1 、D 2 , flow 600m 3 / h, pressure 1.4MP a .

[0055] Table 5 Combination table of controlled rolling and controlled cooling equipment in Examples 1, 2, and 3

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com