Standard one-sided knife edge structure of belt conveyer

A belt conveyor, a standard technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as loss, safety hazards, and reduce the working efficiency of the conveyor to achieve the effect of reducing losses and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

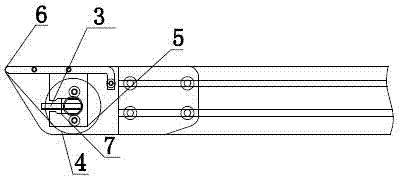

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

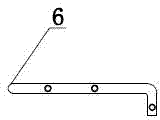

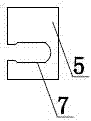

[0015] The standard one-sided blade structure of a belt conveyor according to the present invention includes a roller central axis mounting plate 5, a roller 4, a frame end mounting plate 1, and the two ends of the roller central axis 2 pass through the U-shaped roller central axis mounting plate 5. The card slot 7 is fixed, and the roller central axis mounting plate 5 is fixedly connected to the frame end mounting plate 1. A standard one-sided blade 6 is arranged above the roller central axis mounting plate 5, and the one-sided blade 6 is fixed to the frame end mounting plate 1 at both ends. , The two ends of the drum center shaft 2 are provided with through threaded holes, which are threadedly matched with the adjusting rod 3 .

[0016] When installing, put the two ends of the drum center shaft 2 into the U-shaped slot 7 on the drum cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com