Sewing machine with adjustable needle rod and take-up stroke

A sewing machine and needle bar technology, applied in the field of sewing machines with adjustable needle bars and thread take-up strokes, can solve problems such as increased plant cost, increased equipment or machine purchase cost, etc., and achieves reduced purchase cost, rapid adjustment and transformation and stable combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

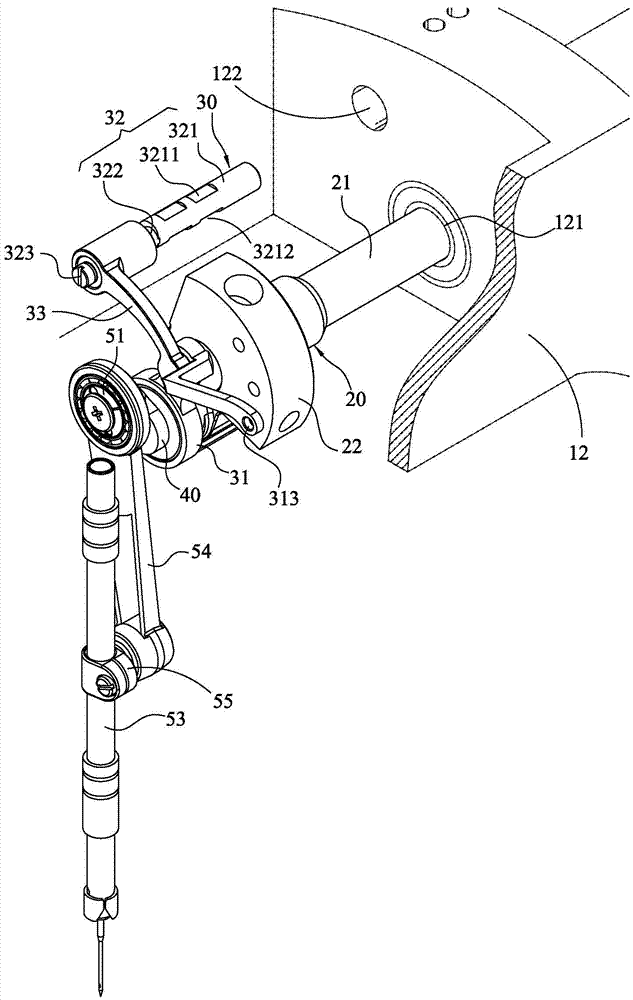

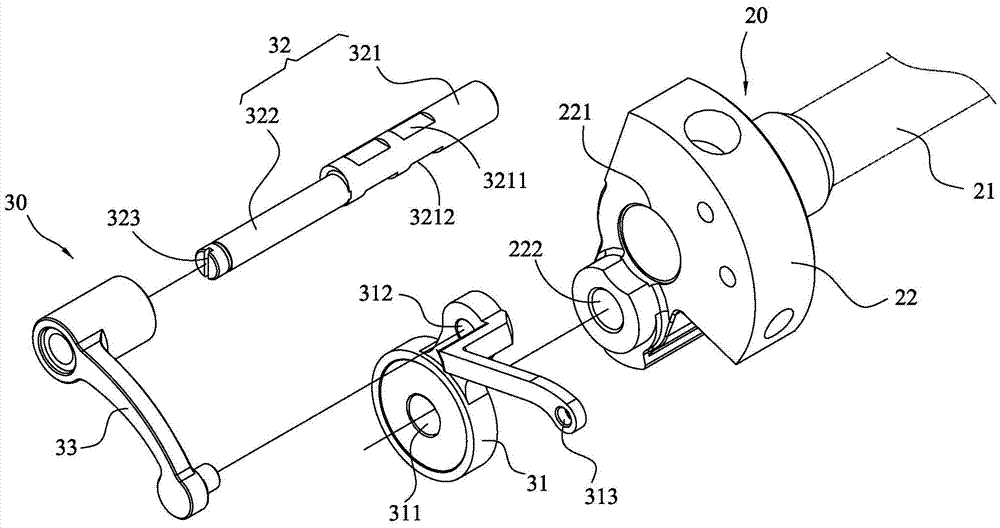

[0036] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only provided for reference and description, and are not used to limit the present invention.

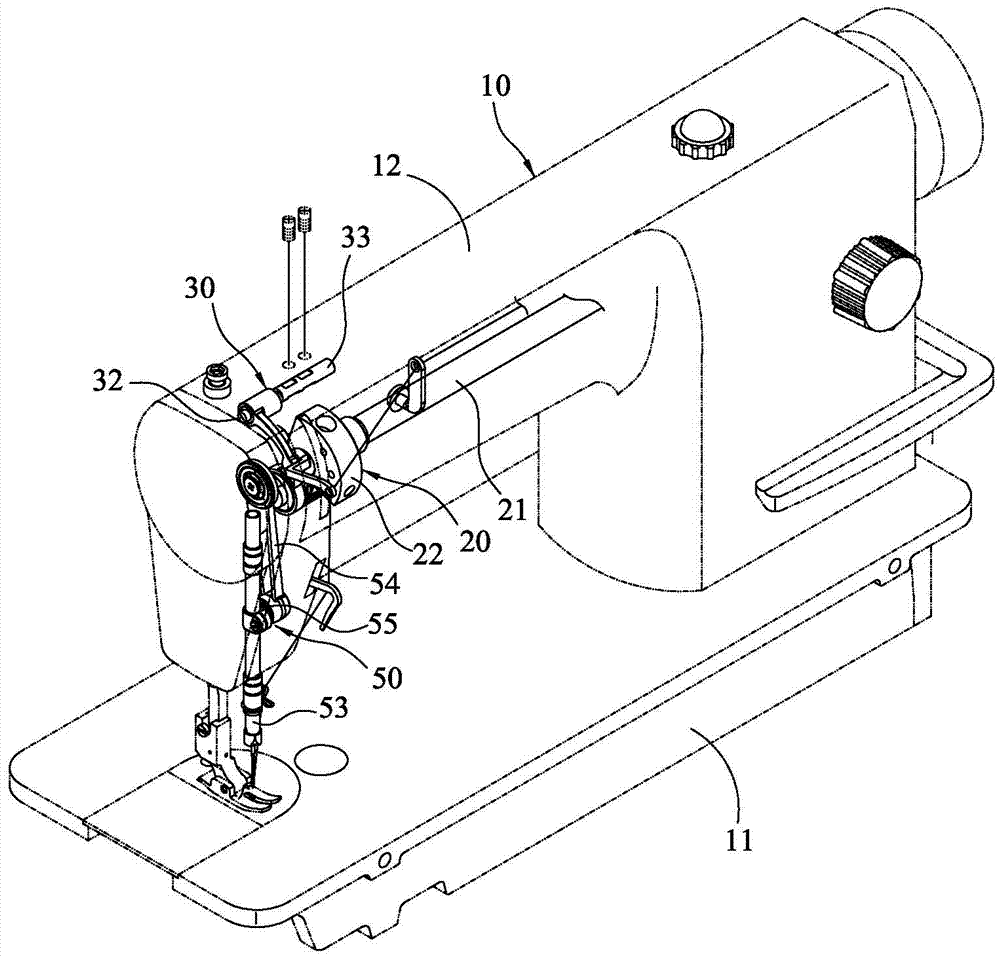

[0037] see Figure 1 to Figure 4 , the present invention provides a sewing machine with an adjustable needle bar and a thread take-up stroke. The sewing machine of this embodiment is a single-needle lockstitch sewing machine, which mainly includes a body 10, a main shaft transmission mechanism 20, a thread take-up transmission mechanism 30. A crankshaft 40 and a needle bar transmission mechanism 50.

[0038] The body 10 includes a base 11 and an L-shaped upper arm 12 connected to the top of the base 11, the upper middle of the upper arm 12 is provided with a first shaft hole 121 (such as figure 2 As shown), in addition, a second shaft hole 122 is opened inside the front section of the upper arm body 12, and the second shaft hole 122 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com