Thread feeding apparatus for an automatic embroidering machine

A technology of thread feeding device and embroidery machine, which is applied in the direction of sewing machine thread take-up device, embroidery machine mechanism, embroidery machine, etc., and can solve the problems of impact, long time, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

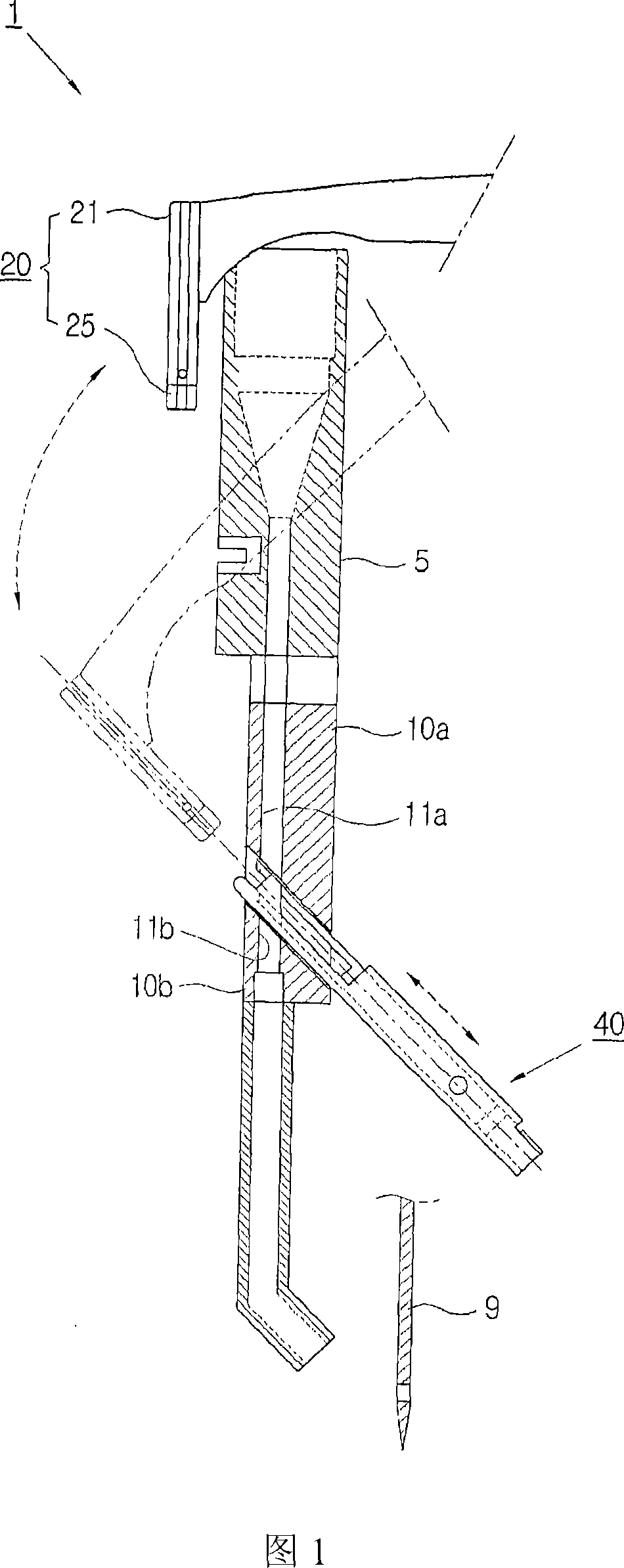

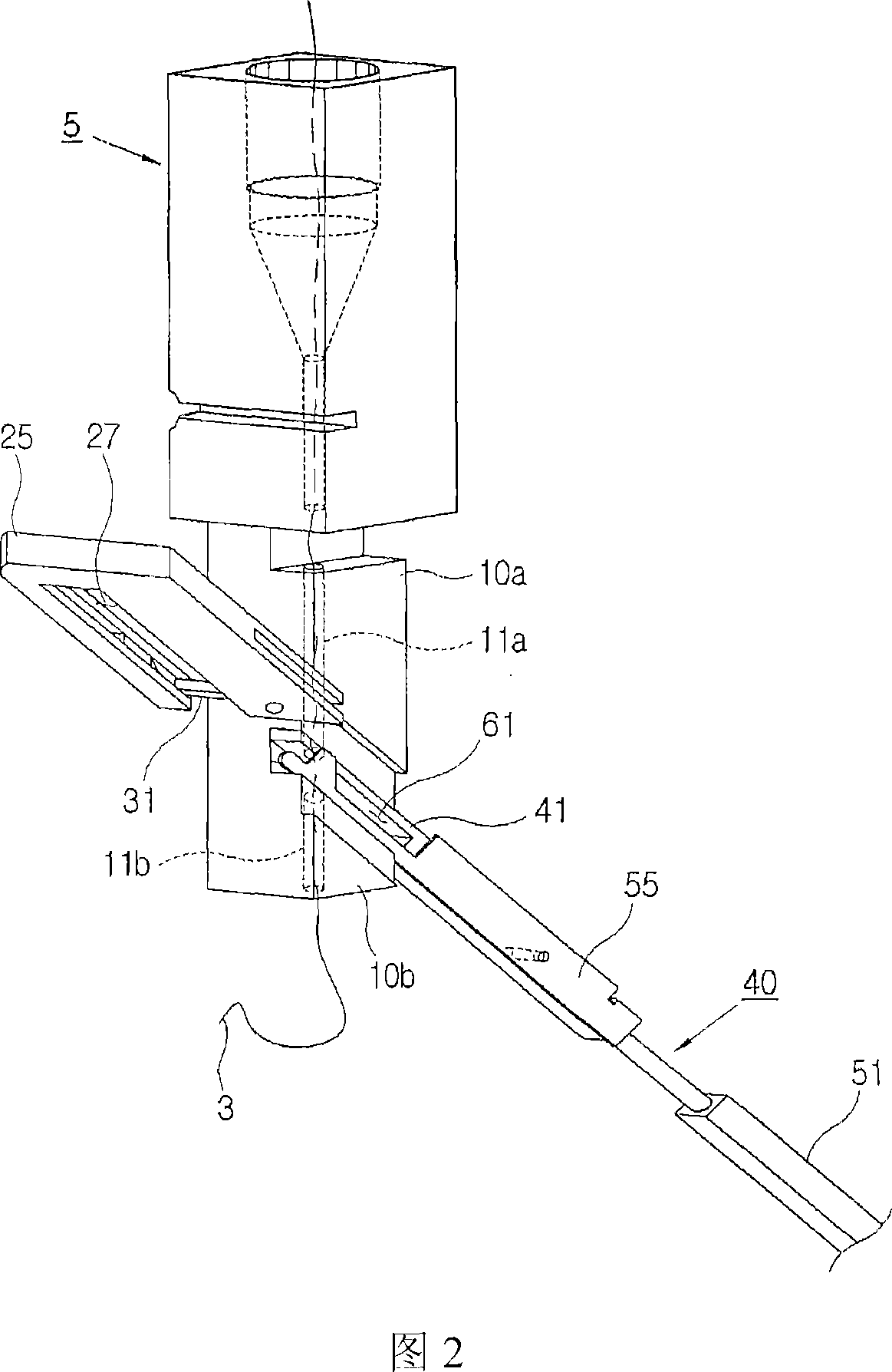

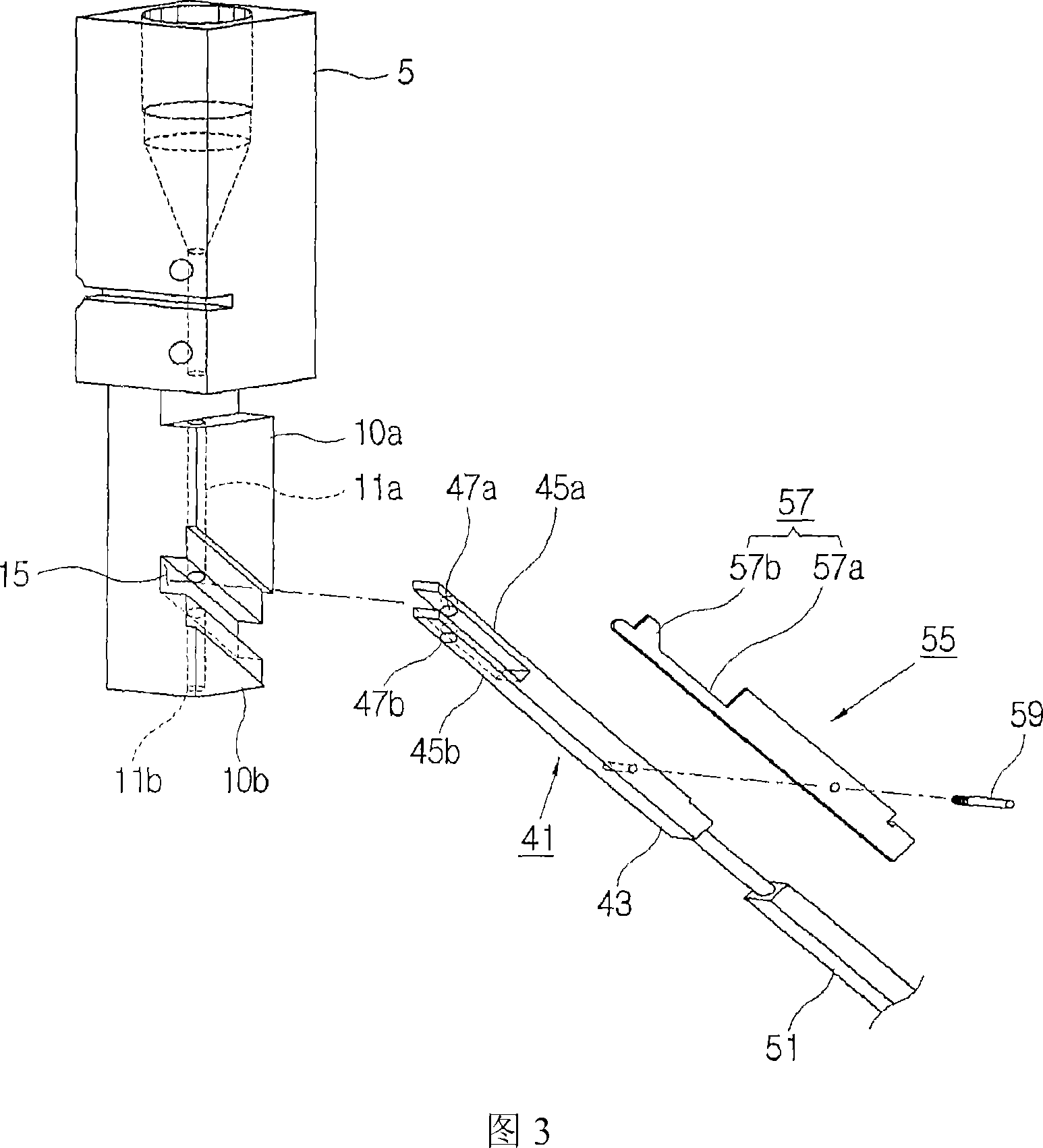

[0028] Next, a single-needle automatic embroidery machine as a first embodiment of the present invention will be described with reference to the accompanying drawings, wherein like reference numerals denote like parts throughout and duplication of description will be avoided as necessary.

[0029] As shown in FIGS. 1 to 4 , the thread feeding device 1 of the automatic embroidery machine according to the first embodiment of the present invention includes: a thread supply unit 5 for supplying one upper thread selected from a plurality of upper threads of different colors a pair of thread guides 10a and 10b for guiding the upper thread 3 supplied from the thread supply unit 5 to the needle 9; a thread pickup unit 20 for picking up the upper thread 3 passing through the pair of thread guides 10a and 10b , and strengthen and release the tension of the upper thread 3; and a thread take-out unit 40 for holding and taking out the upper thread 3 passing through the pair of thread guides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com