Sewing machine

A sewing machine and presser foot technology, applied to sewing machine components, sewing machine thread take-up devices, sewing equipment, etc., can solve the problems of poor appearance of sewing products and failure to form the first stitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings showing preferred embodiments.

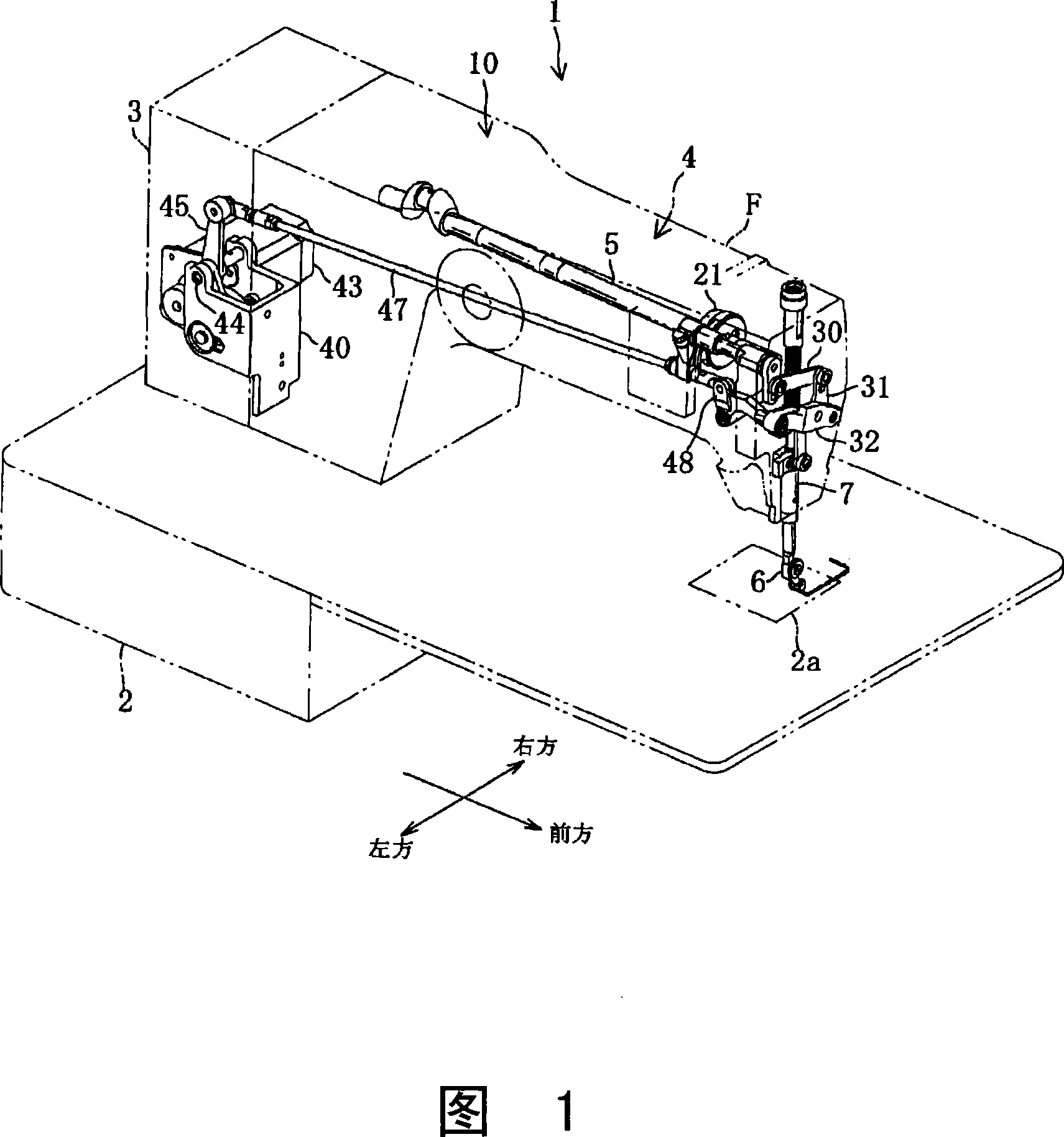

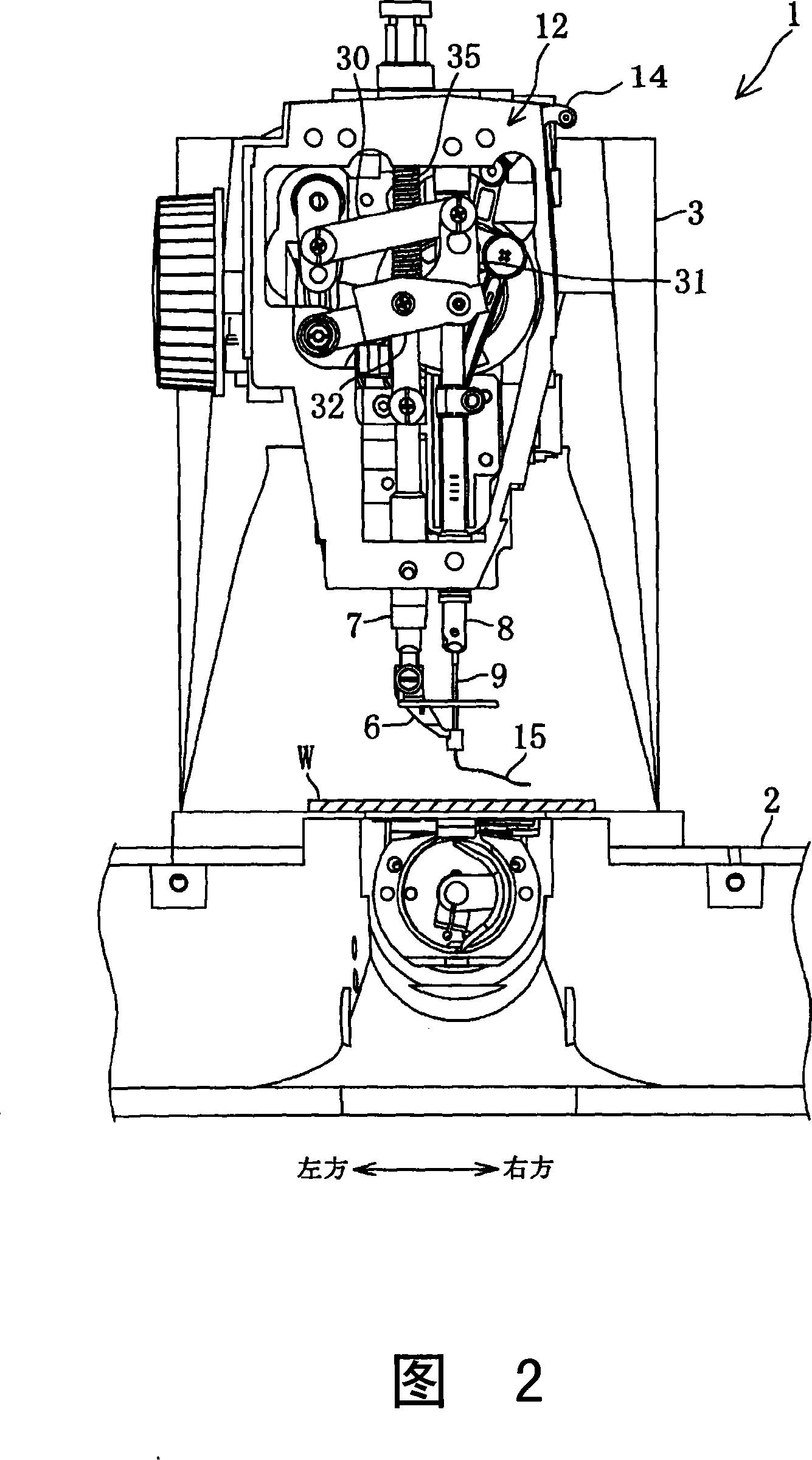

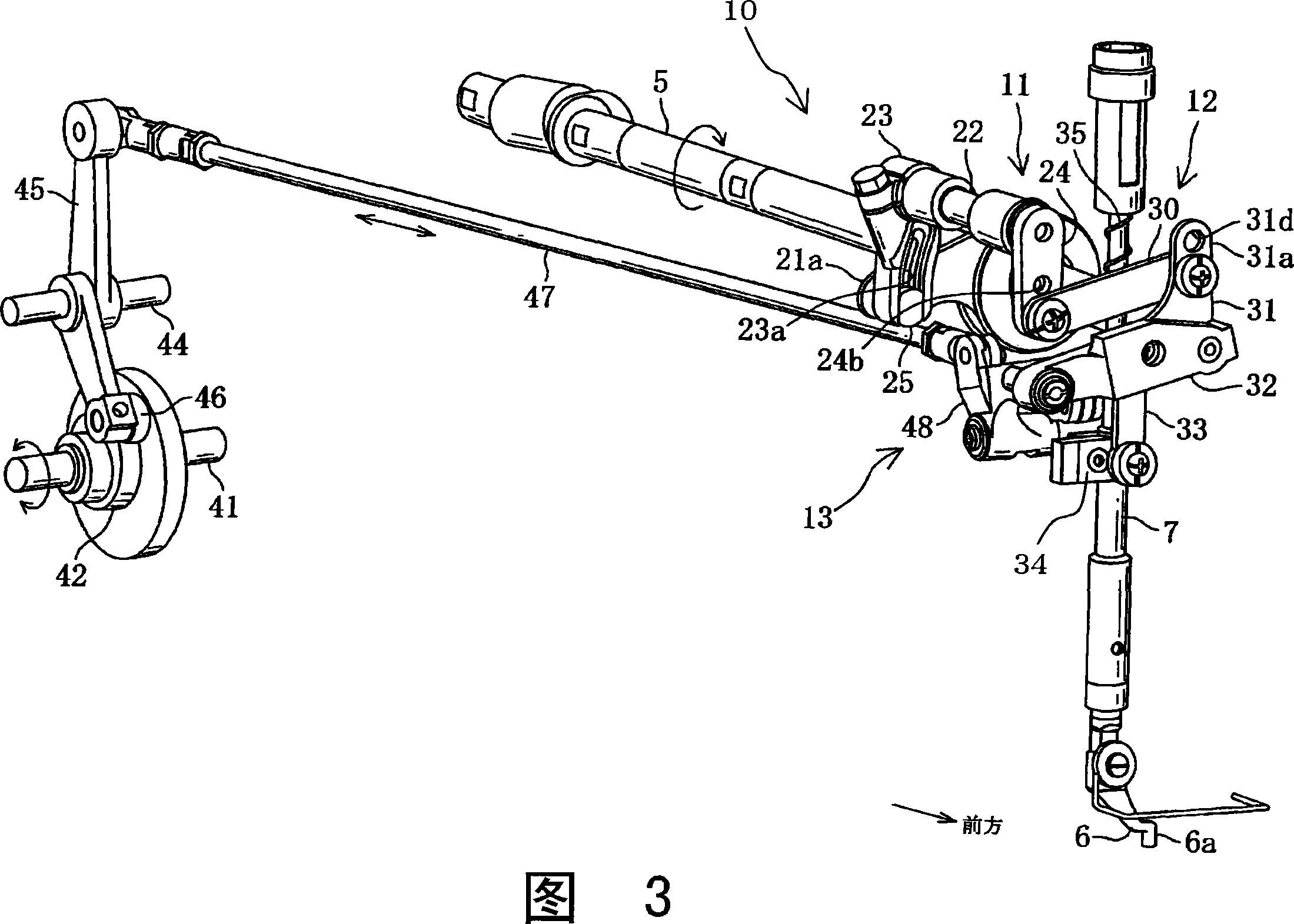

[0035] As shown in FIG. 1 , a sewing machine 1 includes: a bottom plate 2 , a column 3 , and a casing 4 . The upright column 3 is provided in a form standing upward from the rear end portion of the base plate 2 (the upper left in FIG. 1 is the rear). The cabinet 4 is provided in a form extending forward from the upper end of the column 3 . Inside the casing 4, the main shaft 5, which is driven to rotate by a sewing machine motor 63 (see FIG. 12), is arranged along the front-rear direction. As shown in FIGS. 1 and 2 , a needle bar 8 and a pressing bar 7 are provided at the front end of the casing 4 . A detachable sewing needle 9 is installed at the lower end of the needle bar 8 protruding below the casing 4 . A presser foot 6 is fixed to a lower end of a press bar 7 protruding below the cabinet 4 .

[0036] The presser foot vertical drive device 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com