Sewing machine

A technology for sewing machines and electric motors, applied to sewing machine components, sewing machine needle holders, sewing machine thread take-up devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0086]

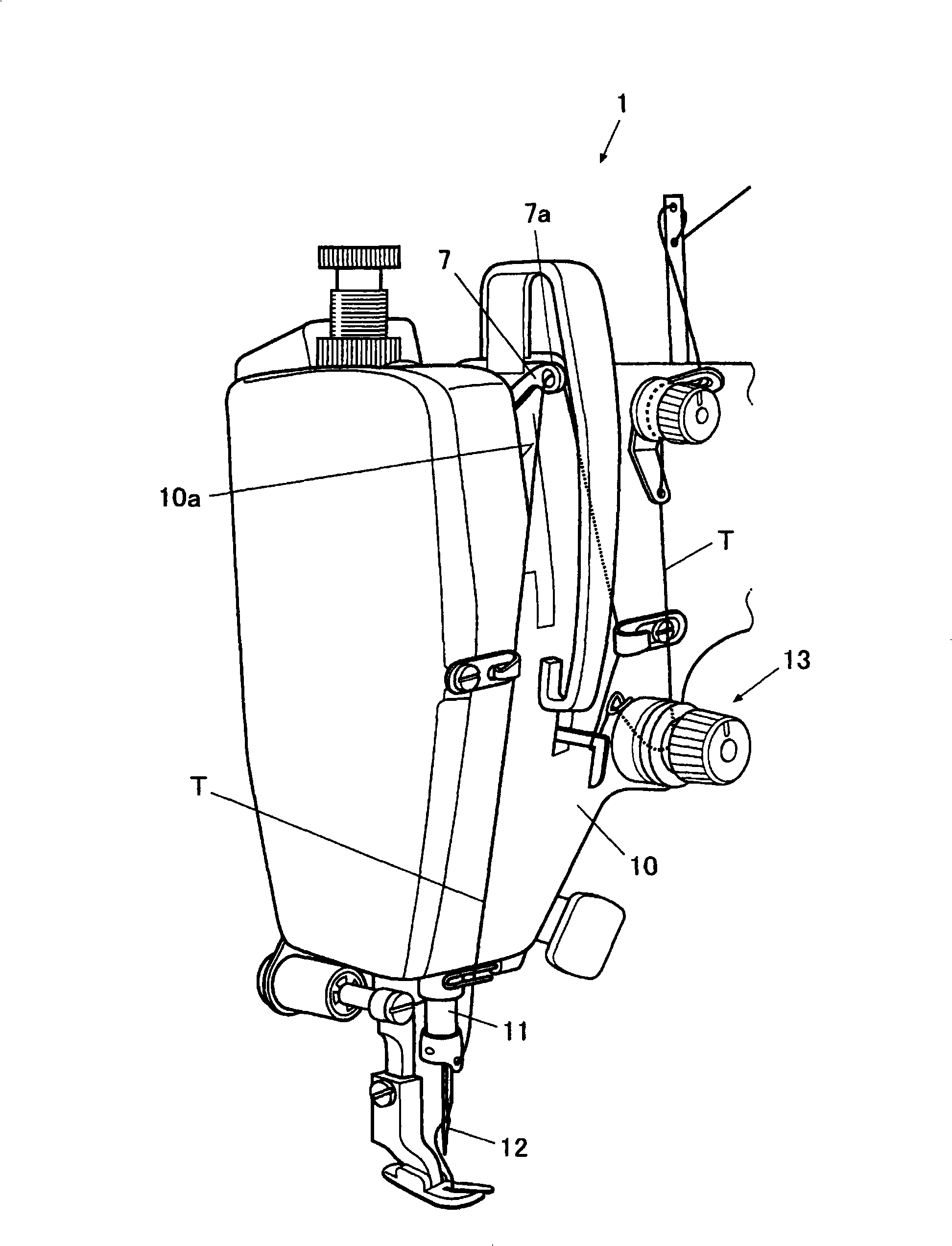

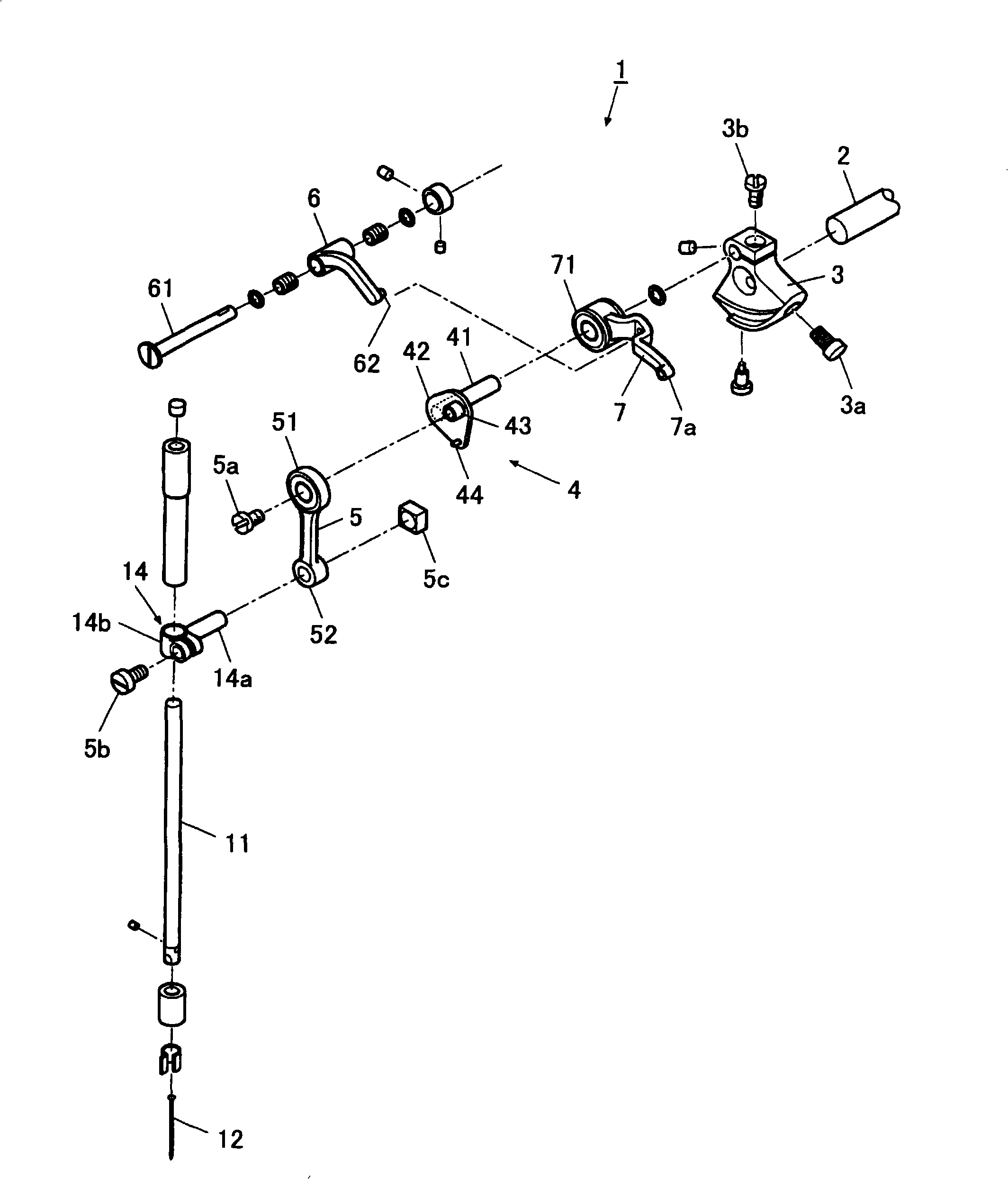

[0087]The needle bar 11 of the sewing machine 1 is supported on the sewing machine frame 102 so as to be movable up and down, and the sewing needle 12 is fixed at the lower end of the needle bar 11 . On the path of the needle thread (thread) T guided from the thread supply source (not shown) to the sewing needle 12, the thread adjusting device 13 is arranged on the front side of the sewing machine frame 10 (the side opposite to the operator). side), adjust the tension applied to the sewing thread T, and arrange the balance 7 along the vertical direction, which makes the thread hanging part 7a at the front end protrude from the balance groove 10a formed on the sewing machine frame 10.

[0088] The suture T is led out from a suture supply source such as a bobbin, hung on the suture adjustment device 13, and passed through the thread hanging portion 7a. Then, the suture T passed through the thread-hanging portion 7 a is guided toward the needle 12 and inserted into the...

Embodiment approach 2

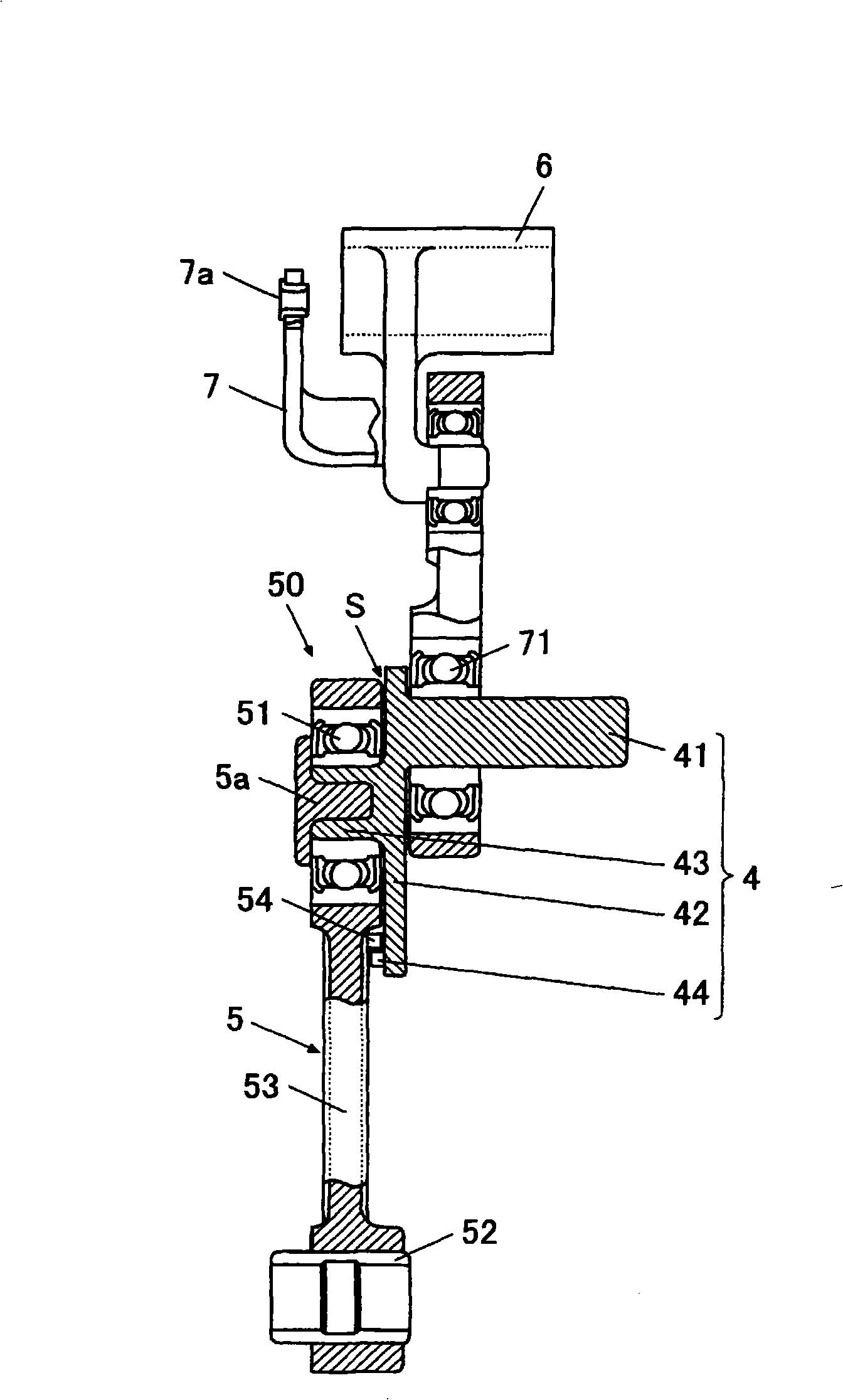

[0125] In addition, as Embodiment 2, for example, as Figure 7 , Figure 8 As shown, a groove portion 42d is formed on the surface of the needle bar crankshaft 4 on the side of the needle bar crankshaft 5, which is opposite to the locus formed by the second convex portion 54a when the upper shaft 2 is rotated by driving the sewing machine motor (refer to Figure 8 The oblique line part), and the second convex part 54a is formed so that the front end part of the second convex part 54a is accommodated in the groove part 42d.

[0126] That is, since the needle bar crank rod 5 swings in the width direction by the rotation of the needle bar crank while moving up and down, the second convex portion 54a moves along a trajectory forming an arc. Therefore, a groove portion 42d is formed on the surface of the needle bar crankshaft 4 as well to follow the movement locus of the tip portion of the second convex portion 54 .

[0127] The groove portion 42d is formed to penetrate from the ...

Embodiment approach 3

[0131] In addition, as Embodiment 3, for example, as Figure 9 As shown, at least a part of the outer periphery of the needle bar crankshaft 4 on the needle bar crank shaft 5 side is provided with a covering portion 42c that protrudes toward the ball bearing 51 and covers the gap V between the needle bar crankshaft 4 and the ball bearing 51 .

[0132] The covering portion 42 c is formed to extend outward from the outer circumference of the ball bearing 51 of the needle bar crank 5 . Accordingly, when the needle bar crank 4 rotates, the thread T is not wound around the ball bearing 51 but wound around the covering portion 42c.

[0133] In addition, the covering portion 42c may be provided over the entire outer circumference of the needle bar crankshaft 4, or may be formed at appropriate intervals so that the thread T does not enter the gap V. As shown in FIG.

[0134] In the case of employing the above configuration, the covering portion 42c covers the gap V between the needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com