Trapping device of computerized seam plaining machine

A lockstitch machine and thread clamping technology, applied in the field of sewing machines, can solve the problems affecting the appearance and sewing quality of sewed fabrics, and the thread ends are left under the fabric, and achieve the effects of improving appearance and sewing quality, beautiful stitches, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

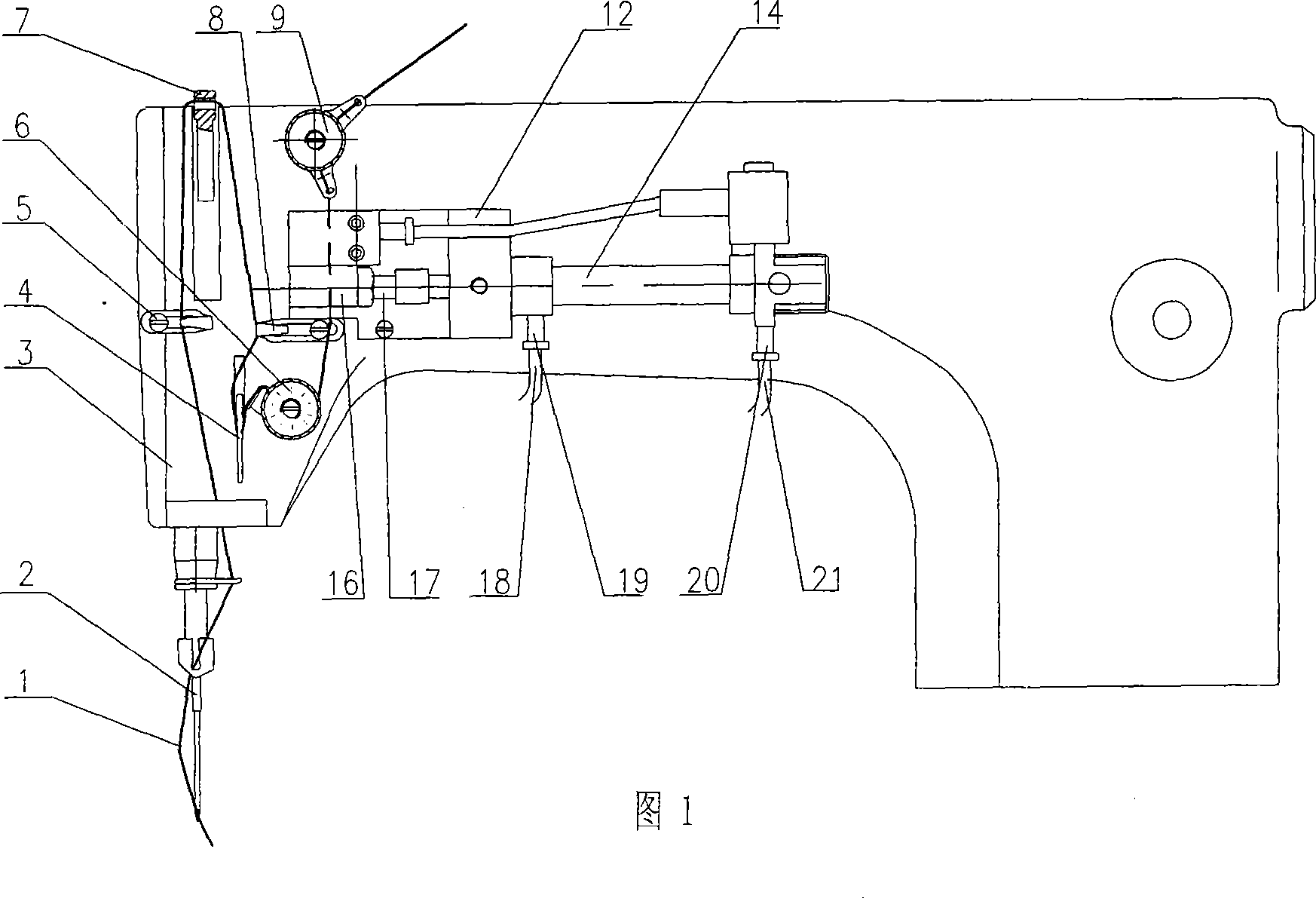

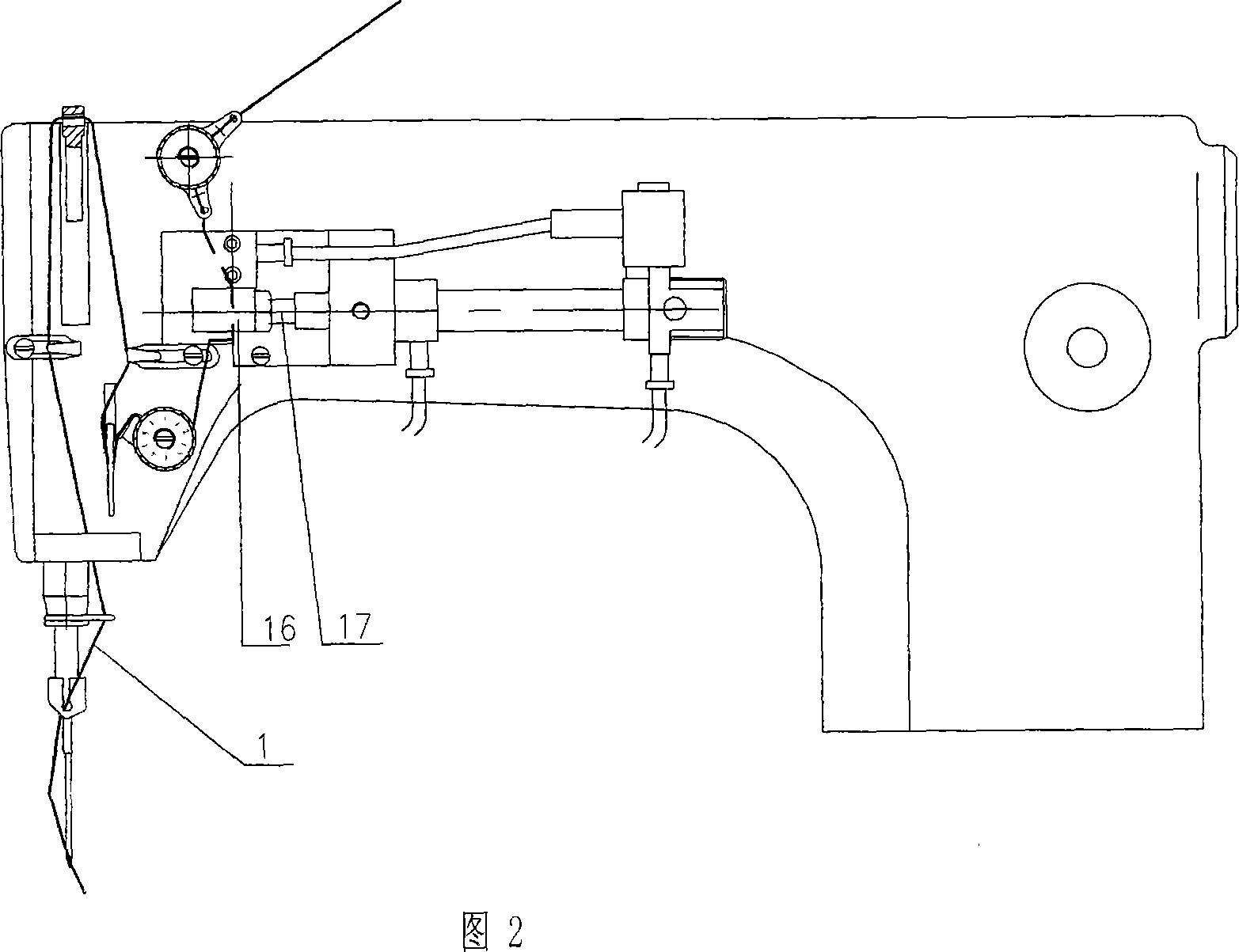

[0014] With reference to Fig. 1, Fig. 2, embodiment 1 adopts cylinder as driving device, comprises cylinder 14, air pipe 13, left air pipe joint 11, right air pipe joint 15, air intake pipe joint 20, air intake pipe 21, air outlet pipe joint 19, air outlet pipe 18 , The pull head 16 that is contained in the cylinder piston rod 17 tops that is made of slide block has the radial through hole (not shown) that suture passes. Cylinder 14 is fixed on the support frame 12 that is positioned at the thread gripper side of sewing machine head, then is fastened on the sewing machine head 3 together with support frame 12, makes the radial through hole on the pull head 16 just in time. Between the clamp nut 9 and the clamp 6. The running path of the suture 1 passes through the small clamp nut 9, the thread puller 16, the thread clamp 6, the slow thread hook 4, the right thread 8, the thread take-up lever 7, the left thread 5, and the needle 2 as shown in the figure. .

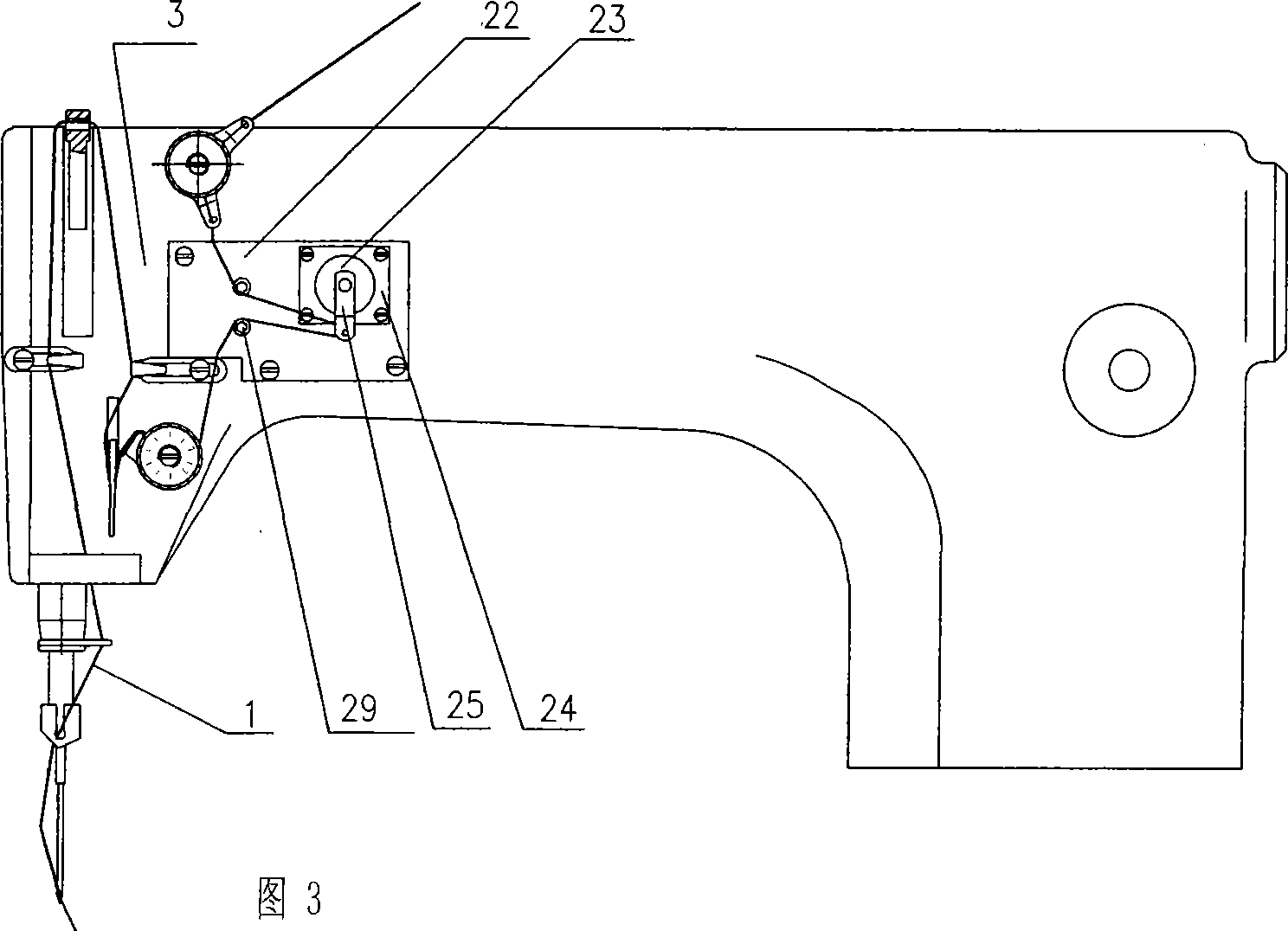

[0015] With refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com