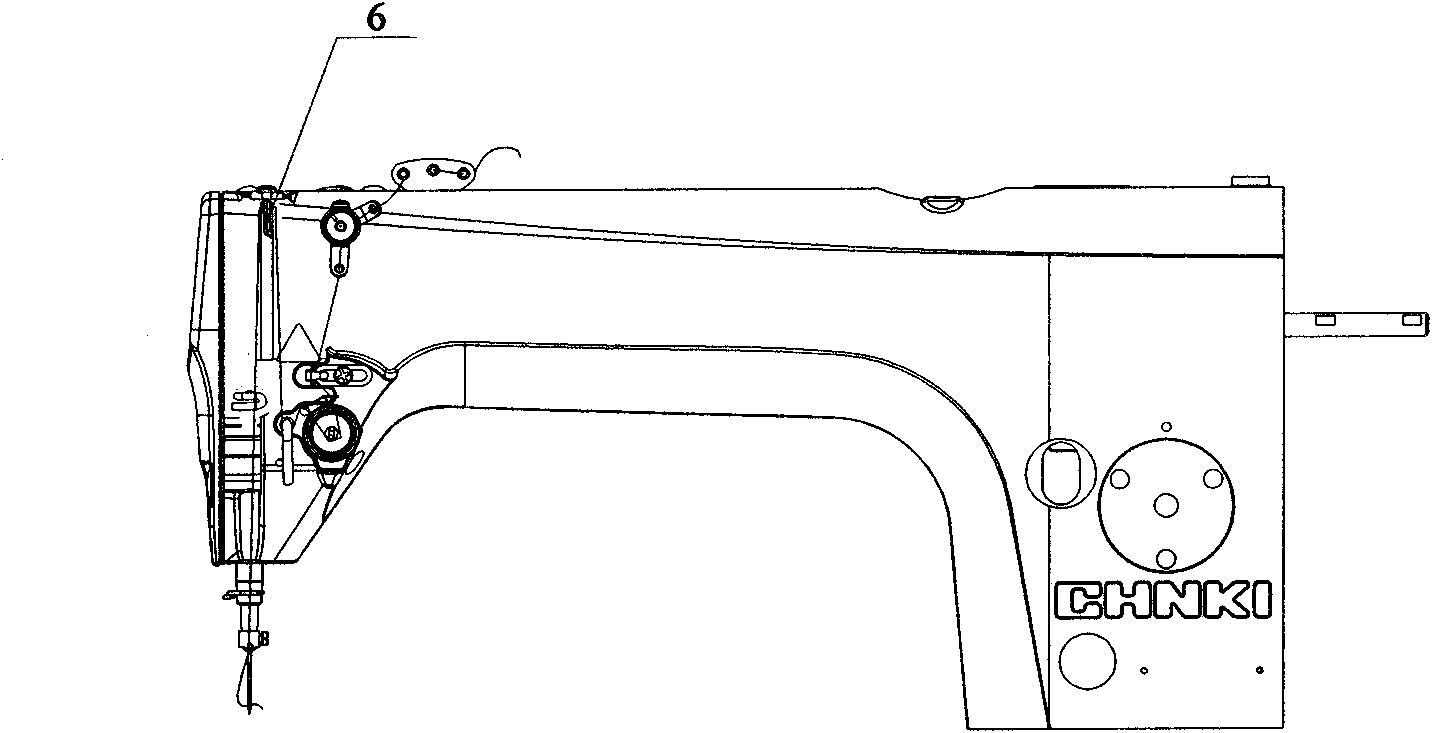

Anti-coiling mechanism of sewing machine

A sewing machine and anti-winding technology, applied in the field of sewing machines, can solve the problem that the end of the sewing thread is easily wound on the thread take-up lever and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

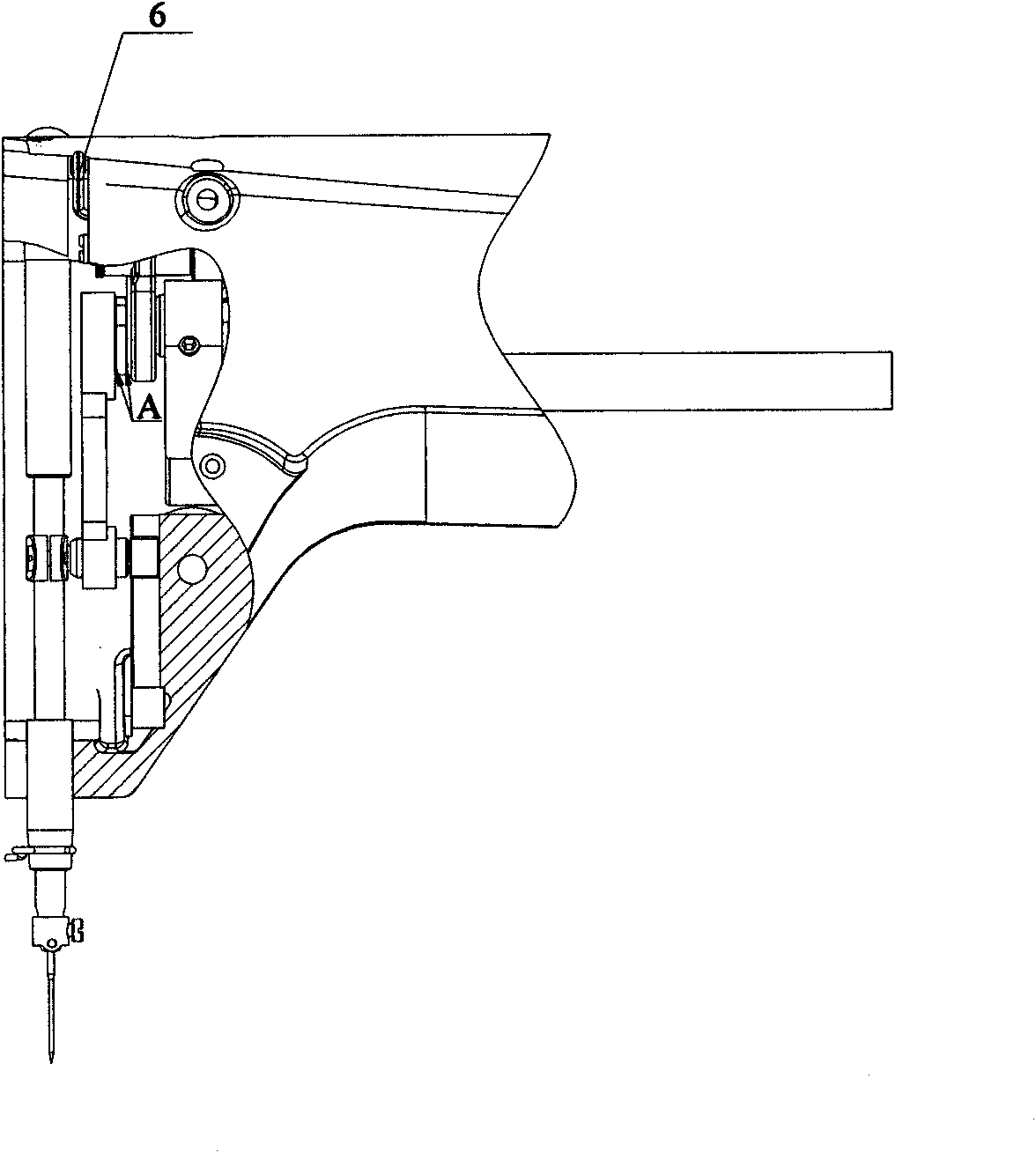

[0016] The anti-winding mechanism of the sewing machine provided by the invention can effectively prevent the broken thread end from being wound on the rotating shaft of the thread take-up lever.

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

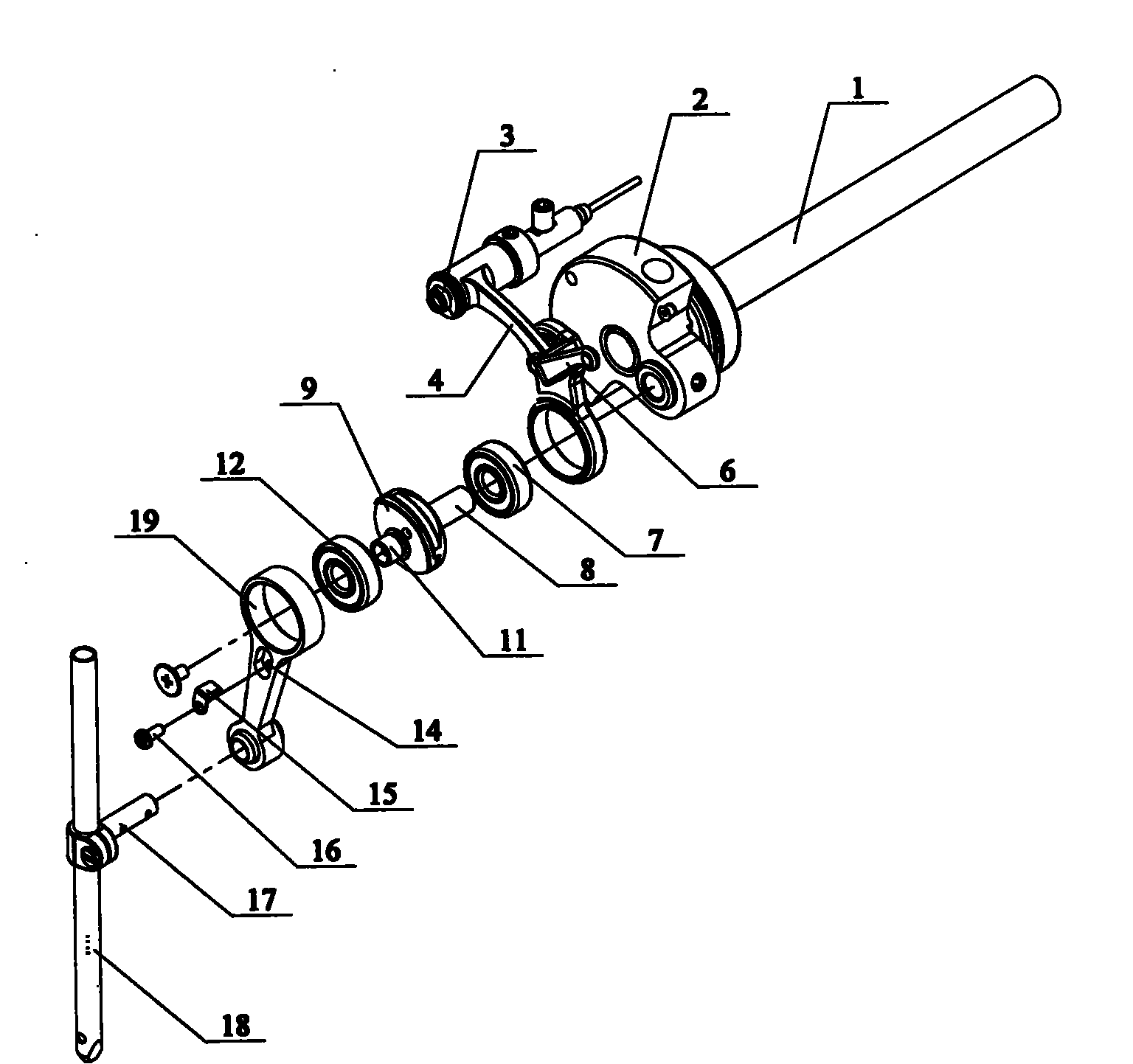

[0018] image 3 A schematic diagram of the exploded structure of the anti-winding mechanism of the sewing machine provided by the present invention, such as image 3 As shown, the sewing machine anti-winding mechanism provided by the present invention includes a needle bar connecting rod 19 and a thread take-up rod 6 which are rotated at the left and right ends of the crank 9. The upper end of wire rod connecting rod 4 is rotated and arranged on the sewing machine casing by bearing pin 3, and the concrete structure of crank 9 is as follows: Figure 4 , Figure 5 shown. The crank 9 includes a disc 91 and left and right rotating shafts 11 and 8 that are eccentrically arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com