Take-up device for sewing machine

A sewing machine and thread rewinding technology, which is applied to the sewing machine thread take-up device, the sewing machine thread hook, sewing machine components, etc., can solve the problems of reduced operability, increased cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

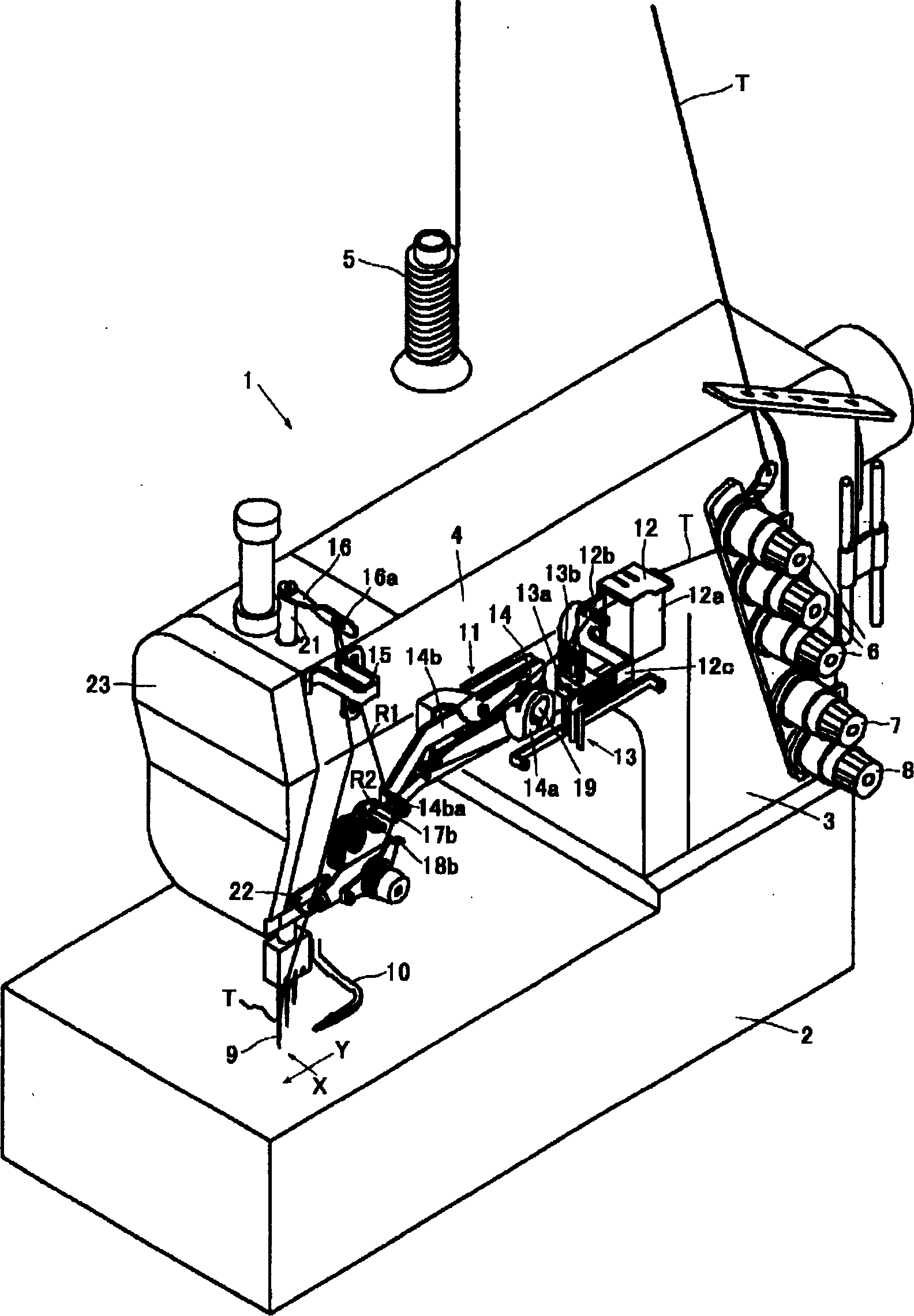

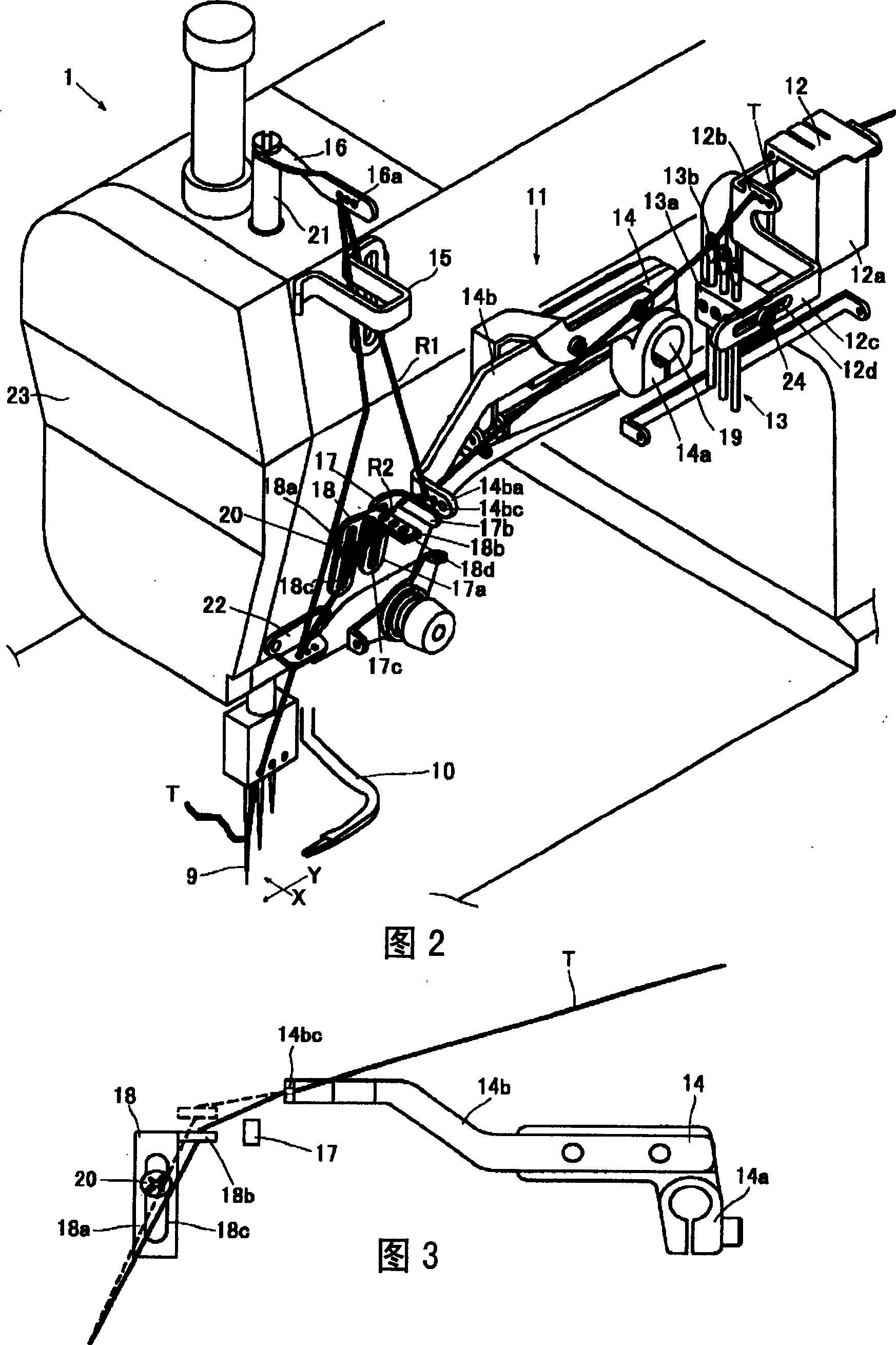

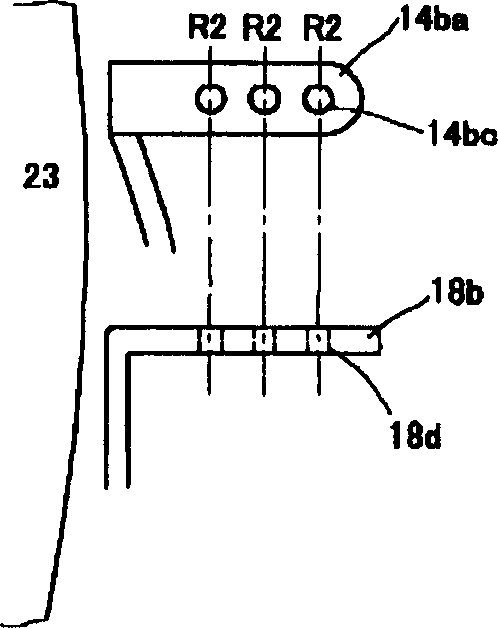

[0028] refer to Figure 1 ~ Figure 4 The first embodiment of the present invention will be described. In addition, only one suture T and one bobbin 5 are illustrated in the drawings, and other sutures and bobbins are omitted.

[0029] figure 1 Shown is a sewing machine 1 for performing decorative sewing or chain stitch decorative sewing as an example of the present invention. This decorative stitch sewing machine 1 is provided with a thread rewinding device 11 for performing a thread pulling operation for pulling the thread T and a thread rewinding operation for loosening the thread T. The frame of the decorative stitch sewing machine 1 is composed of a base plate 2 , a body portion 3 extending upward from the right side of the base plate, and a machine head 4 extending from the body portion 3 parallel to the base plate 2 .

[0030] Further, on the upper portion of the decorative stitch sewing machine 1, a bobbin 5 supported by a bobbin stand (not shown) is arranged. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com