Lock-type chain stitch sewing machine

A sewing machine and stitch technology, which is applied to sewing machine components, sewing machine thread take-up devices, sewing machine ferrule mechanisms, etc., can solve problems such as obstructing thread passages and overall space problems, and achieve the effect of reliable operation and overall space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

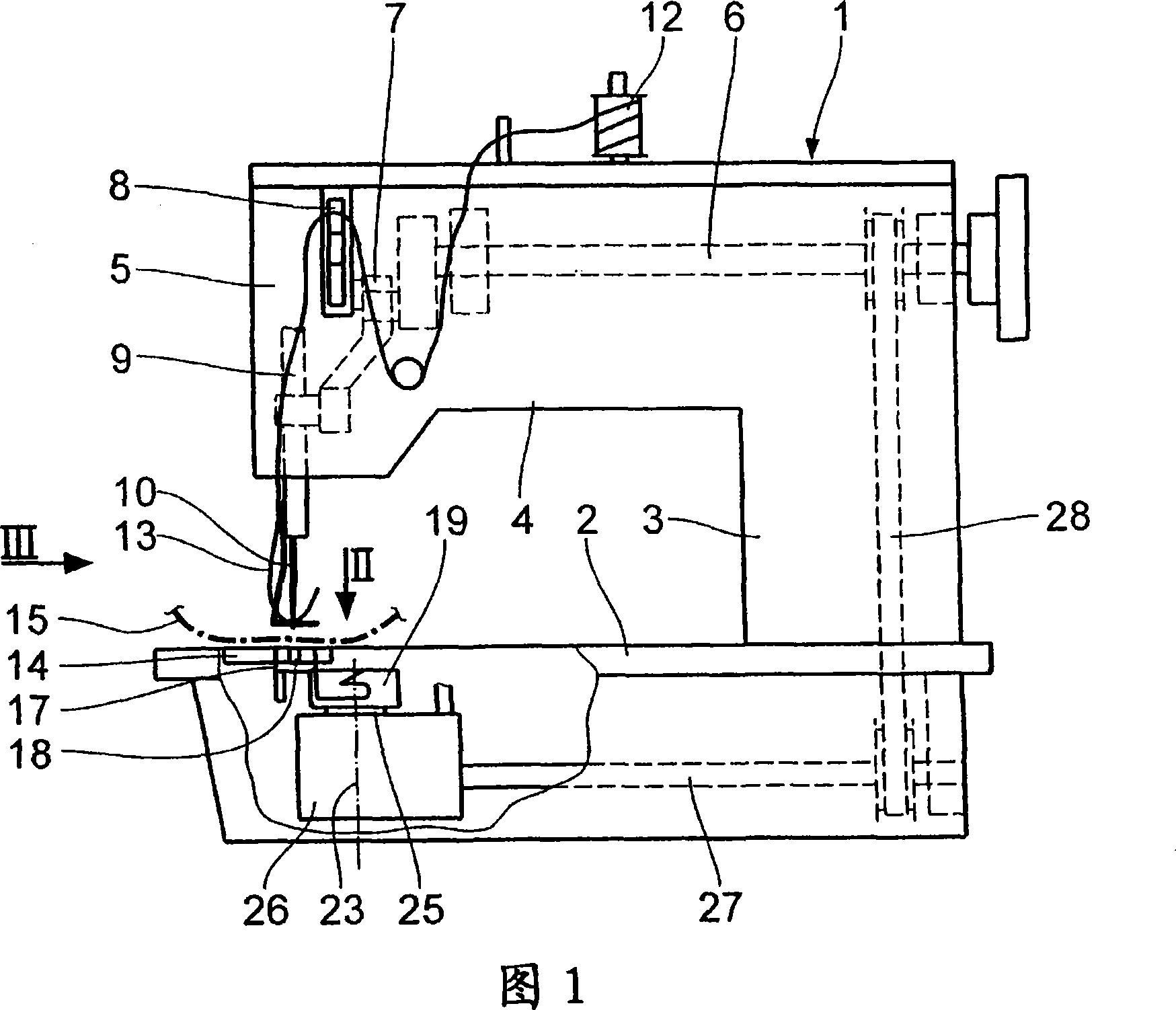

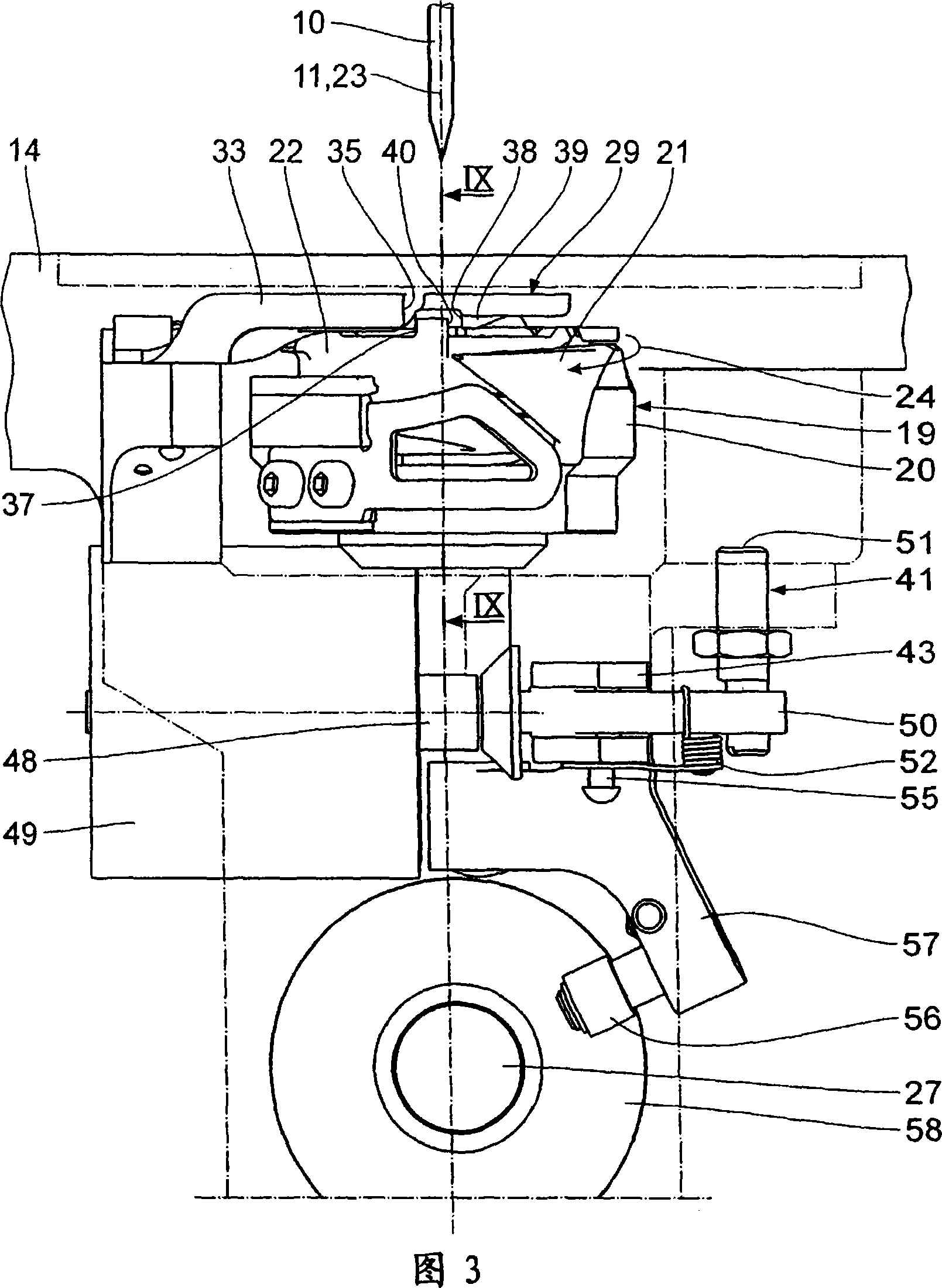

[0027] A bartack sewing machine 1 has a base plate 2 with a post 3 extending upwardly from the base plate and an angled arm 4 . The arms terminate at the head 5 . An arm shaft 6 is rotatably installed in the arm 4 . Inside the head 5 , the arm shaft drives a crank gear 7 via a guide rod 8 . The crank gear 7 is drivingly connected to a needle bar 9 which is mounted axially displaceable in the head 5 . The needle bar has a needle 10 at its lower end. The needle 10 can be raised or lowered on the vertical axis 11 by means of the crank gear 7 . The needle 10 guides in its eye the needle thread 13 supplied by the bobbin 12 via the thread tensioner and the guide rod 8 .

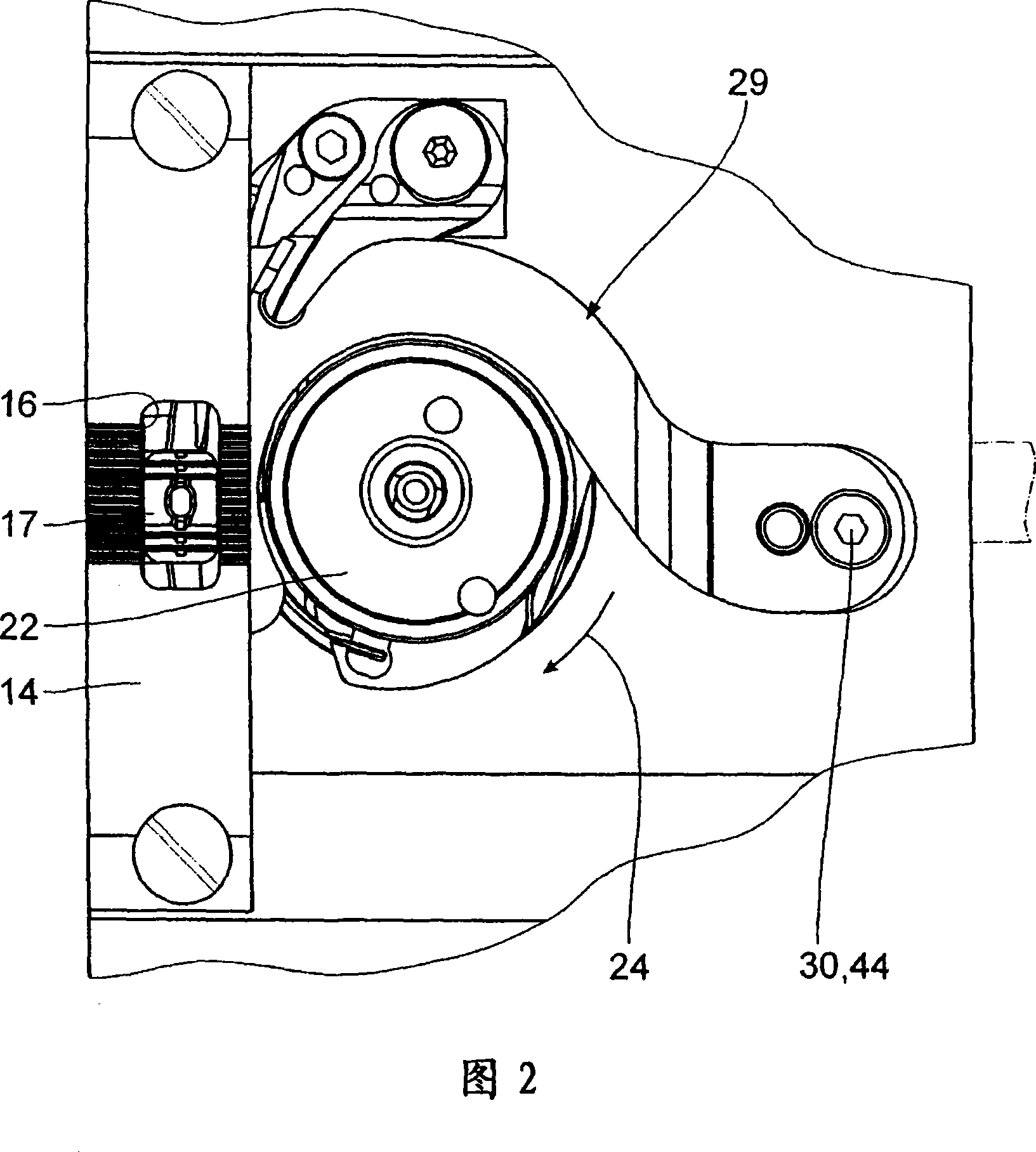

[0028] The base plate 2 carries a screwed support plate 14 on which a sewing workpiece 15 is placed. The support plate 14 is configured with a recess 16 for the passage of a feeder 17 . The feeder has stitch holes 18 for the passage of needles 10 . The feeder 17 is positioned in a known manner in driving con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com