Sewing machine

A sewing machine and sewing needle technology, which is applied to sewing machine components, sewing machine needle holders, sewing machine thread take-up devices, etc., can solve the problems of no public methods, reduce the difference in sewing conditions, improve sewing quality, and realize individual parts. number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] [Summary of Embodiment]

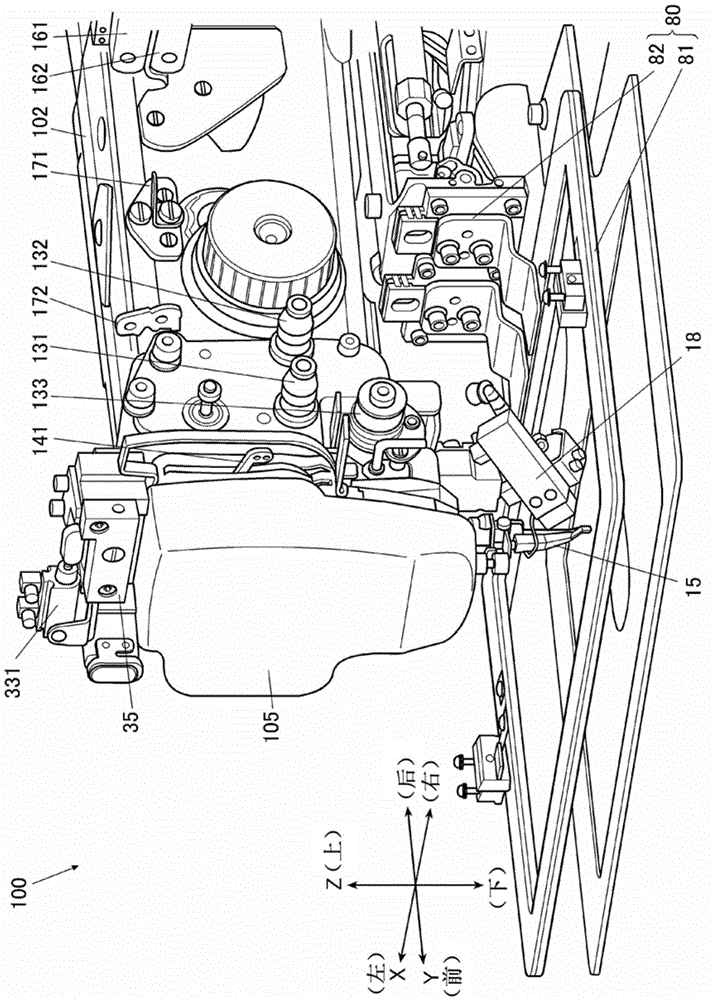

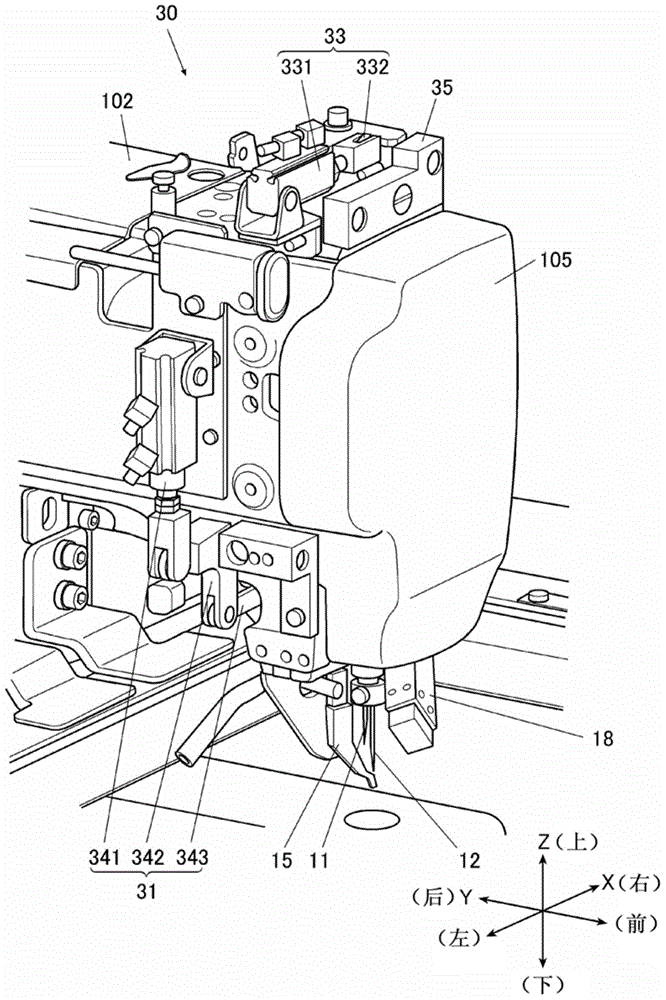

[0098] based on Figure 1 to Figure 12 , the embodiment of the present invention will be described.

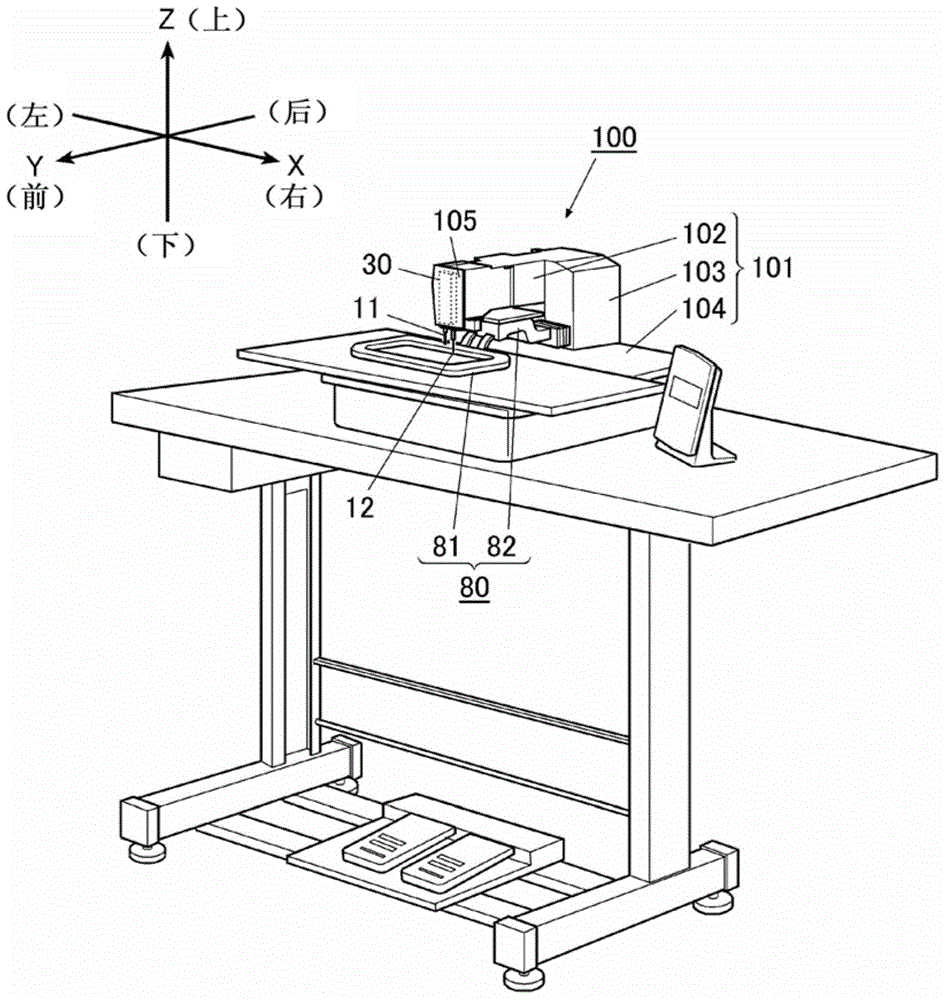

[0099] The sewing machine 100 described below as this embodiment is a so-called electronic cycle sewing machine, and has a holding frame as a cloth holding part for holding a cloth as a sewing object to be sewn. The holding frame relatively moves with respect to the sewing needle, and a sewing pattern based on predetermined sewing data is formed on the cloth held by the holding frame. In addition, this sewing machine 100 has two needle bars 110, 120, and the needle bars 110, 120 can be switched and selectively used. Thus, for example, two types of upper threads U1, U2 having different characteristics such as color and thickness can be inserted into the needles 11, 12 attached to the respective needle bars 110, 120, respectively, and sewing patterns can be formed using the two types of upper threads.

[0100] figure 1 is a perspective view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com