Machine version based online detection and control method of near field electrospinning printing effect

A machine vision, jet printing technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of high subjective judgment and operating experience requirements, too subjective judgment, uneven wire diameter, etc. Stable and controllable micro-nano 3D printing, solving the effects of poor printing effect and uniform and controllable wire diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

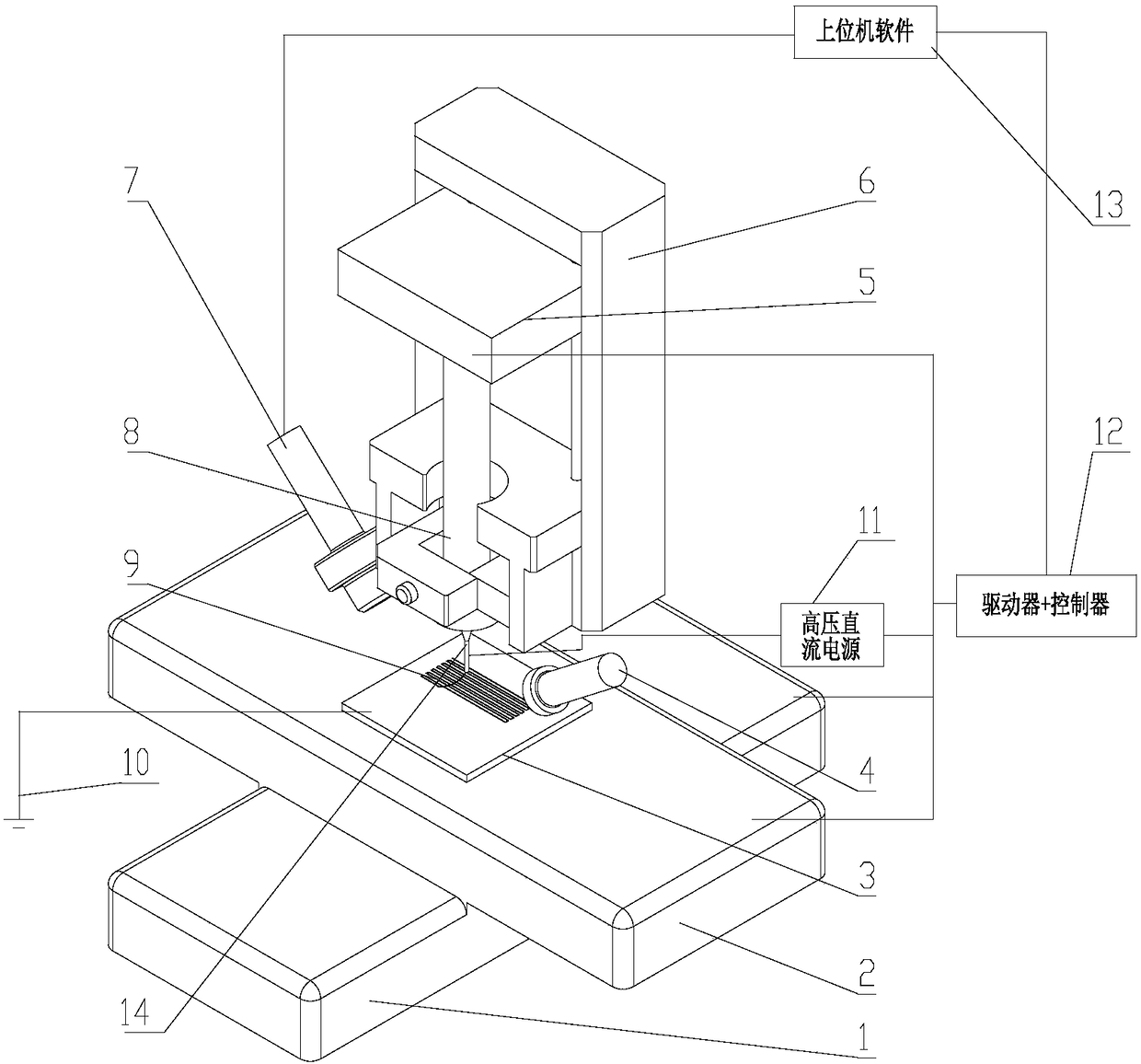

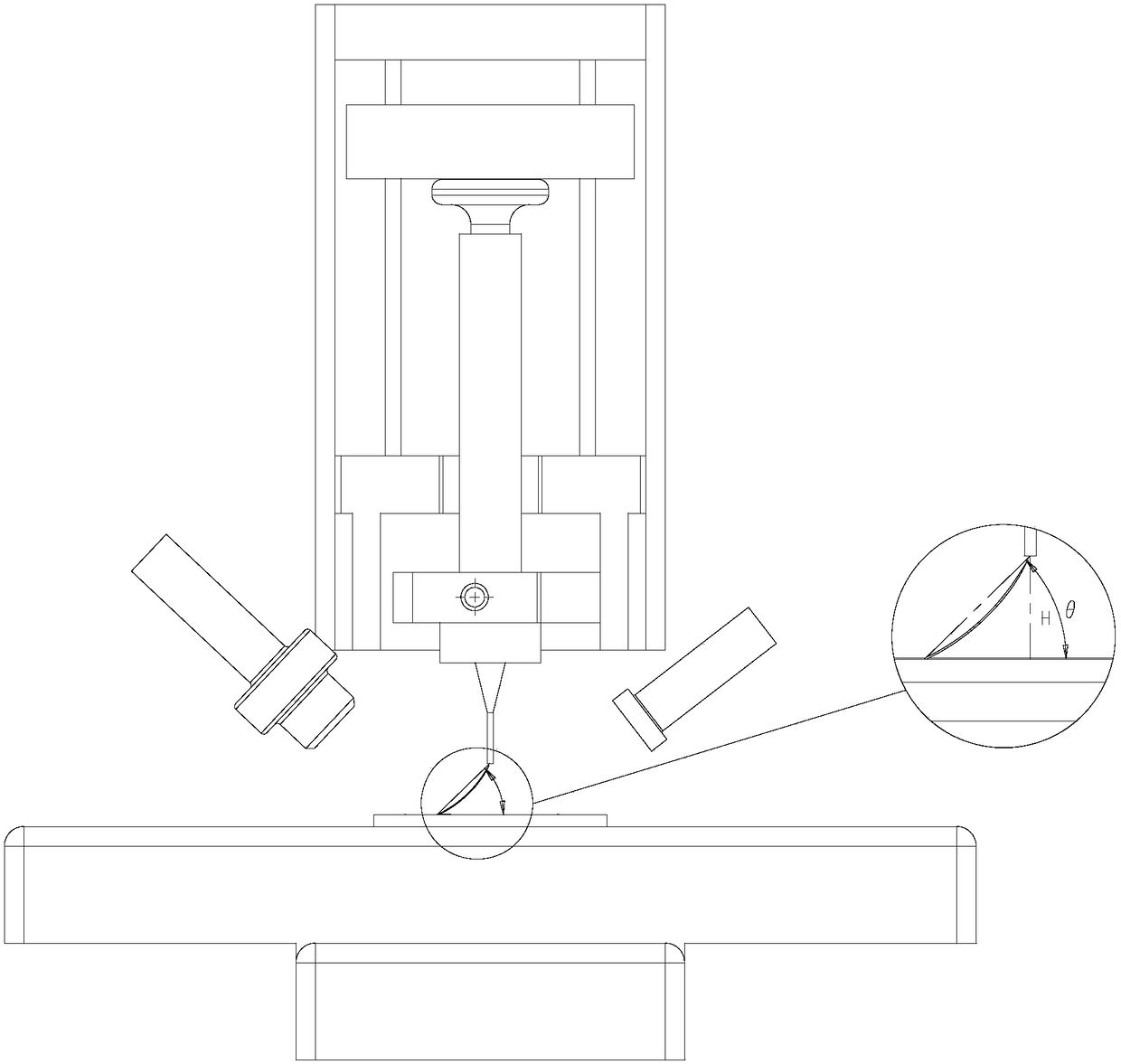

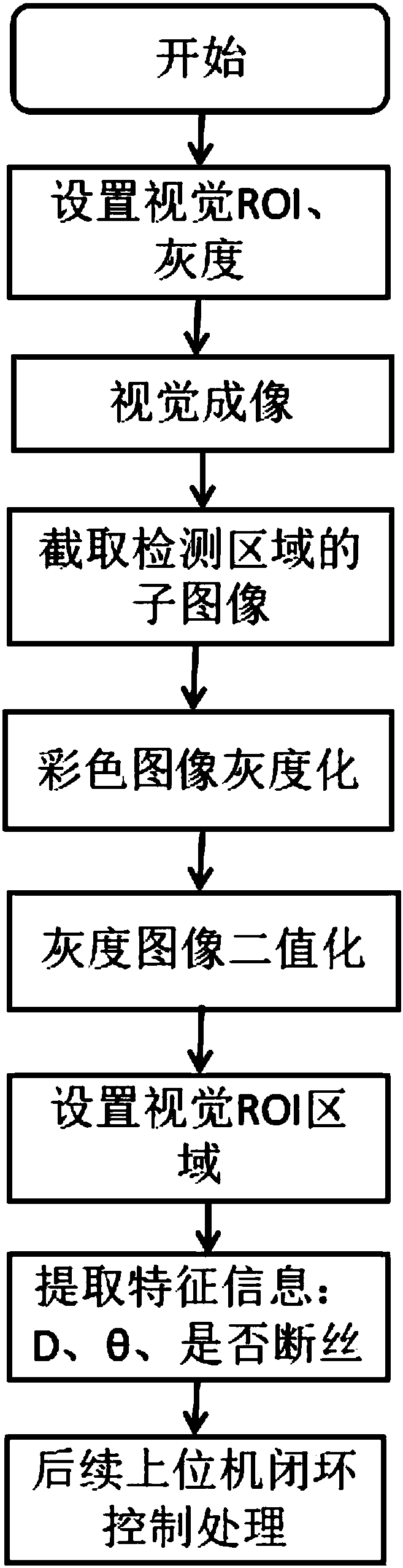

[0031] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a near-field electrospinning jet printing effect online detection and control method based on machine vision. It is a one-way open-loop control. The wire diameter and the drawing shape of the wire are easily disturbed during the printing process, resulting in uneven wire diameter, wire bifurcation, and broken wires. However, in the traditional near-field electrospinning printing process Detection and control mainly rely on manual observation cameras, so there are problems of too subjective judgment and difficult adjustment. Therefore, the present invention can provide a machine vision-based online near-field electrospinning jet printing effect detection and control method to solve the problem of jet printing quality. The present invention is a near-field electrospinning printing effect online detection and control method based on machine vision. The principle of electrofluid jet print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com