Production technology and production line of high-strength PET (polyethylene terephthalate) flat yarn for freight bag

A production process and high-strength technology, applied in the production of complete sets of equipment for artificial threads, filament/thread forming, heat treatment of artificial filaments, etc., can solve problems such as easy deformation, avoid broken threads, high strength, and optimize drafting Effect of Process Parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

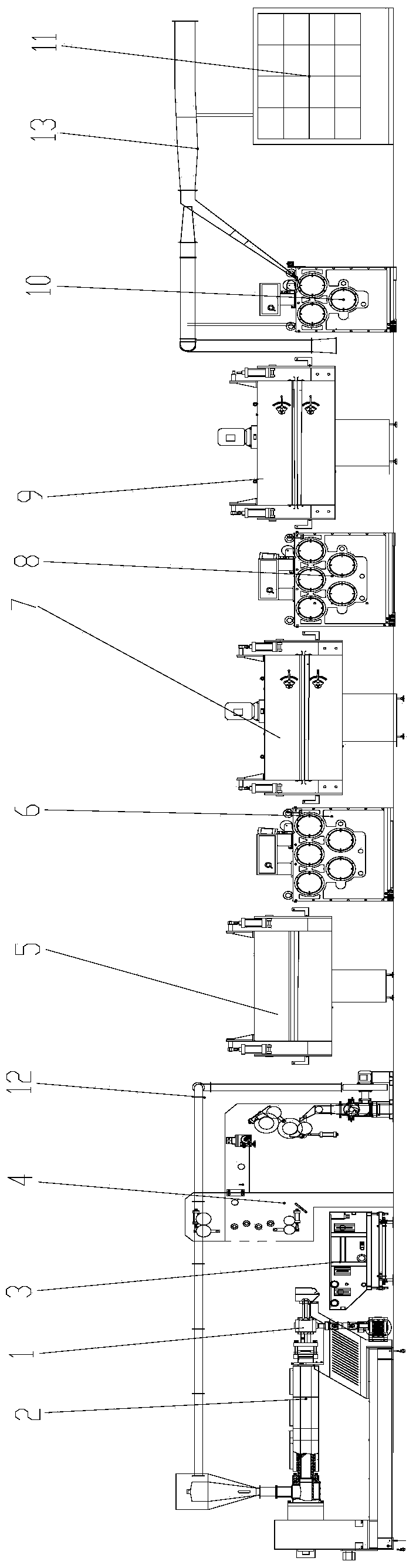

[0021] Such as figure 1 As shown, (1) crush waste PET bottle materials (recycled mineral water bottles) (if necessary, add appropriate amount of additives, such as tougheners, antioxidants or fillers, etc., according to actual production needs) into pieces smaller than 15x15mm The pellets, after drying, are added to the extruder 2, and the temperature of the extruder is set at 260-270°C. The raw material enters the metering pump 1 in a molten state through the extruder, and the metering pump 1 measures the molten PET material into the die head as required. , and extrude from the narrow slit of the die head, and form a PET film after cooling in the cooling tank 3 with a temperature of 50-60°C;

[0022] (2) Use the cutting device 4 to cut the film in the longitudinal direction, and then pass it through the drafting hot water tank 5 under the condition of 100°C under the action of the first drafting roller 6 (drafting five rollers). Once drafting, the drafting ratio is 2.5 to 3 ...

Embodiment 2

[0026] (1) Put low-viscosity (0.68-0.8d1 / g) PET new material (if necessary, add appropriate amount of additives, such as toughening agent, antioxidant or filler, etc., according to actual production needs) at 150-170 ° C Pre-crystallization, and then add extruder 2, set the temperature of the extruder to 250 ~ 270 ℃, the raw material enters into the metering pump 1 in a molten state through the extruder, and the metering pump 1 will meter the PET material in the molten state into the mold as required The head is extruded from the narrow slit of the die, and the PET film is formed after cooling by water in the cooling tank 3;

[0027] (2) Use the cutting device 4 to cut the film in the longitudinal direction, and then pass it through the drafting hot water tank 5 under the condition of 100°C under the action of the first drafting roller 6 (drafting five rollers). Once drawn, the draw ratio is 2.5 to 3 times; under the action of the second draft roller 8 (drawing five rollers), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com