An ultrasound and magnetic field-assisted wire cut electrical discharge machining method and device

A technology of electric discharge wire and ultrasonic magnetic field, applied in the field of ultrasonic magnetic field-assisted wire electric discharge machining methods and devices, can solve the problems of affecting machining accuracy and machining efficiency, affecting the integrity of the machining process, and decreasing the stability of machining, etc. Achieve the effect of preventing short circuit and wire breakage, shortening time and cost, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

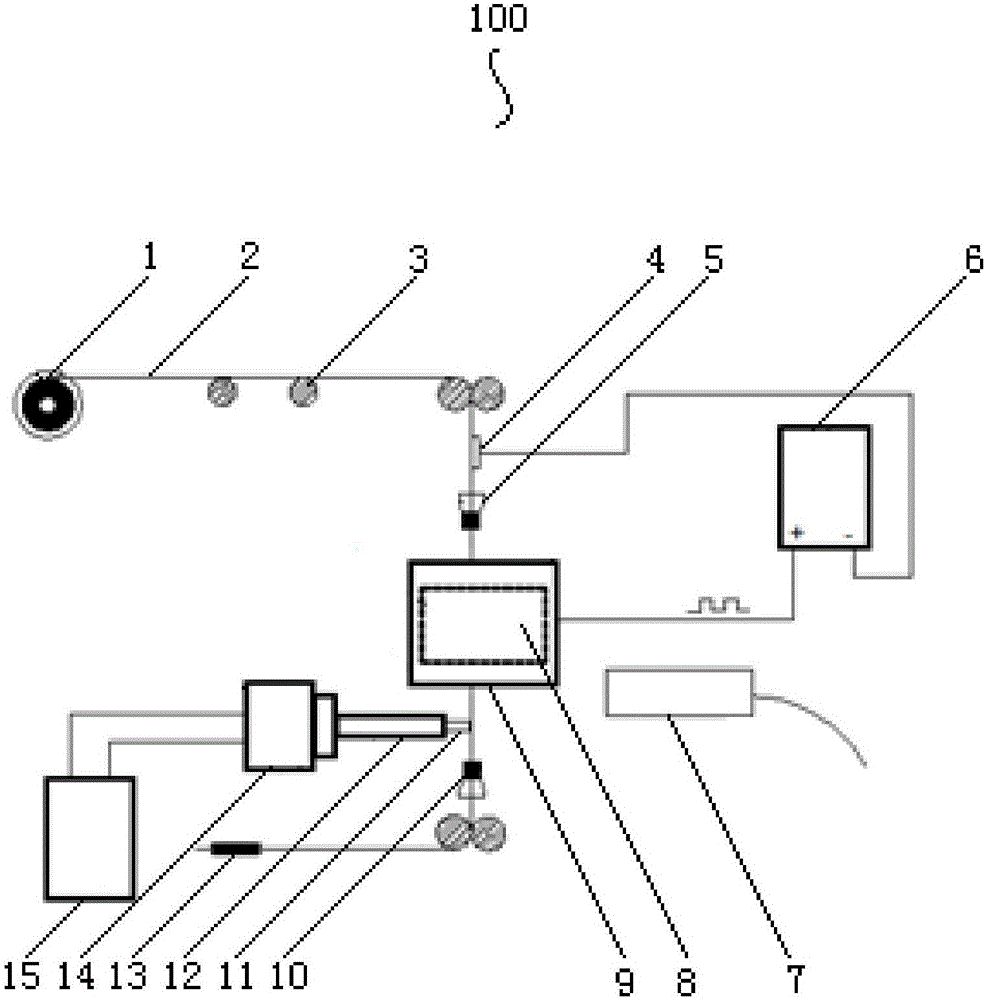

[0020] figure 1 It is a schematic diagram of a wire electric discharge machining device assisted by an ultrasonic magnetic field of the present invention.

[0021] Such as figure 1 As shown, a wire electric discharge machining device 100 assisted by an ultrasonic magnetic field of the present invention includes a workbench, a wire electrode device, a pulse power supply 6, an ultrasonic generator and a magnetic field device.

[0022] Workbench is used for installing and fixing workpiece 8. The workpiece 8 is fixed on the workbench by a special fixture, and an acoustic emission sensor 7 is installed near the workpiece 8 for real-time collection of acoustic emission signals generated during processing.

[0023] The wire electrode device has a wire storage cylinder 1, a plurality of conductive rollers 3 and guides, and in this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com