Warping system

A tensioning frame, reciprocating technology, used in warping machines, textiles and papermaking, manufacturing tools, etc., can solve the problems of broken threads, wear of rotating parts, wear of warp yarns, etc., to avoid wear and broken threads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

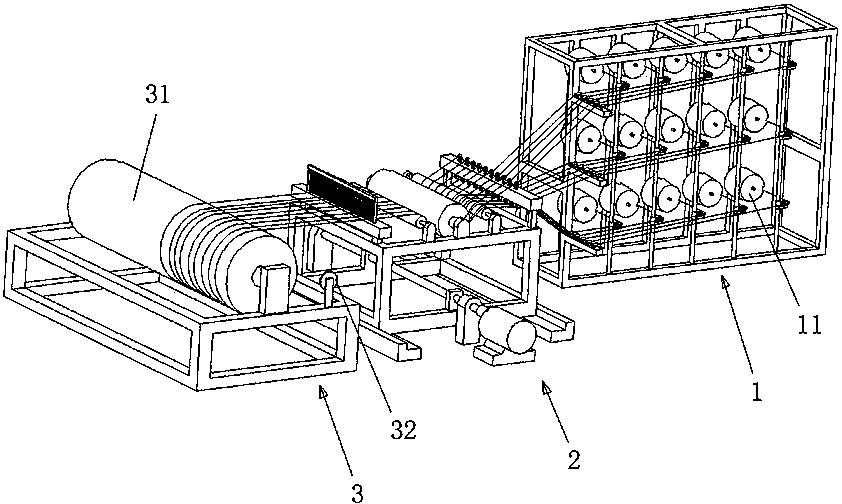

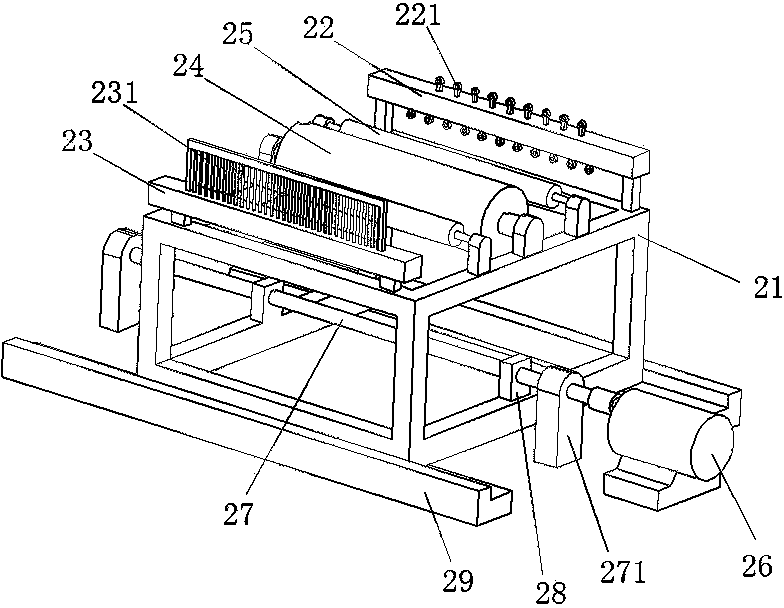

[0015] Examples such as figure 1 and figure 2 Shown: a warping device, including a creel 1, a tensioning mechanism 2 and a take-up mechanism 3, the creel 1 is provided with multiple layers, each layer is inserted with a cheese 11. The tensioning mechanism 2 includes a tensioning frame 21 and a rotating member arranged on the tensioning frame 21 . The winding mechanism 3 includes a yarn reel 31 and a speed measuring and length measuring device 32, and the reel 31 is driven by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com