Method for improving fine enamelled wire spot welding strengh in spot welding

A kind of enameled wire, subtle technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of broken wires, wire falling off, etc., to prevent falling off, eliminate hidden dangers of circuits, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

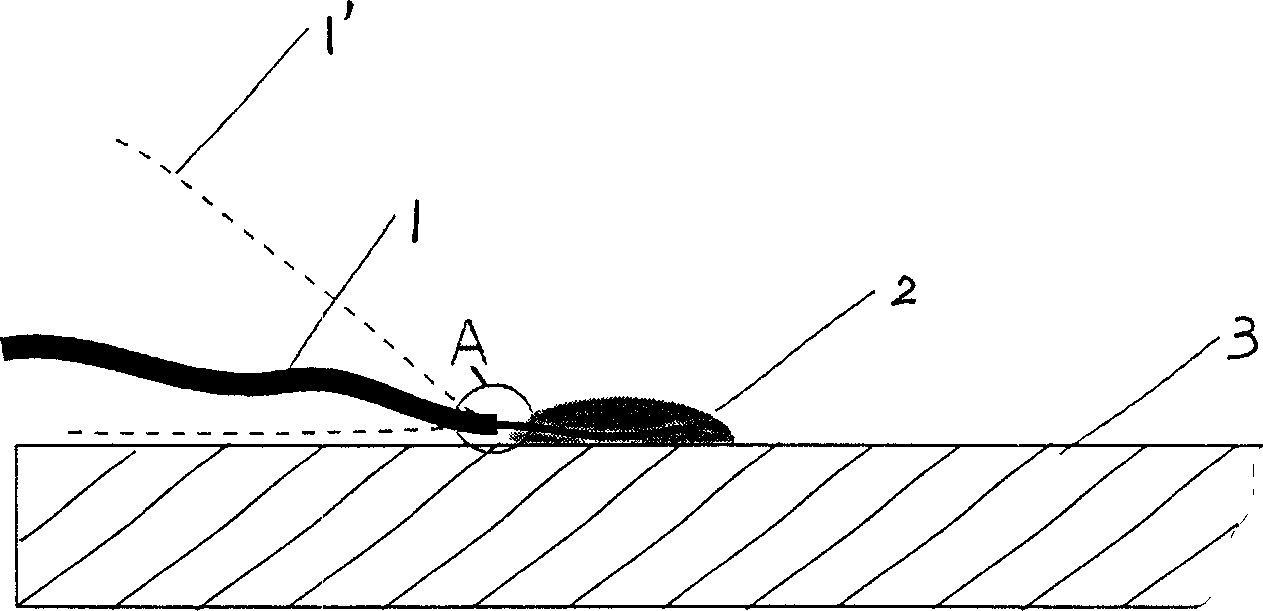

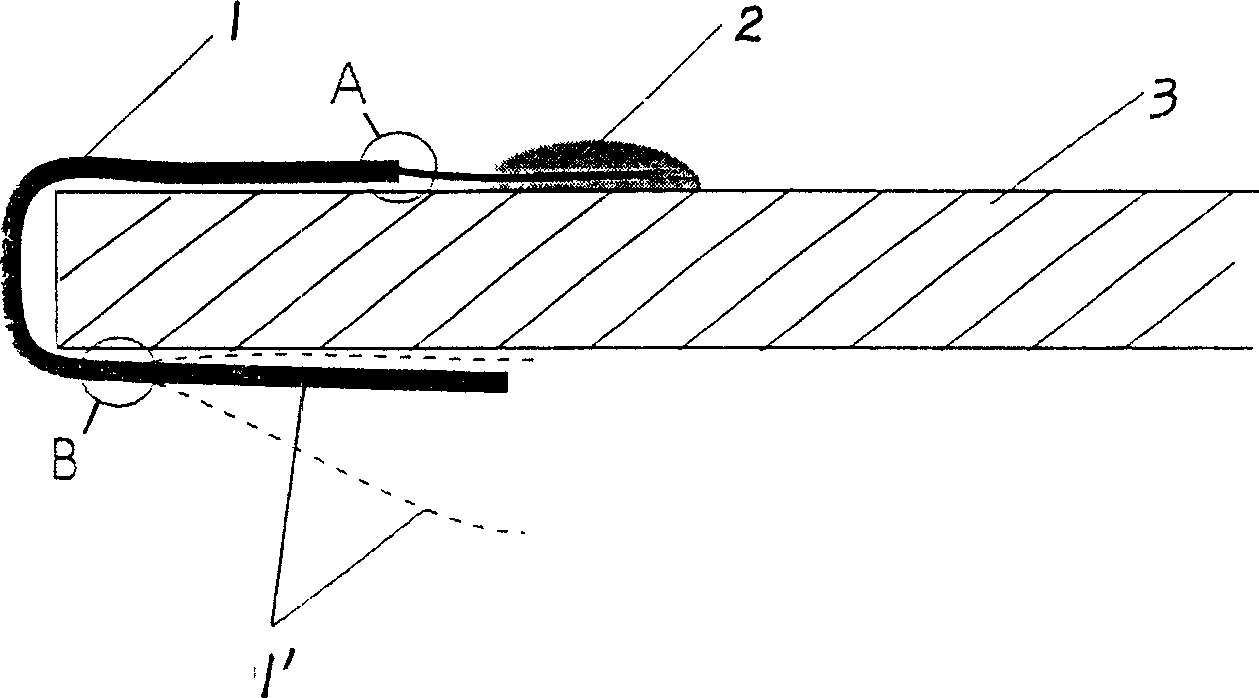

[0014] Such as image 3 Shown is one of the embodiments of the present invention, the fine enameled wire 1 and the circuit board 3 are welded to each other through the solder joint 2, the fine enameled wire 1 and the solder joint 2 intersect at point A, and the point A is close to the board surface of the circuit board 3. The fine enameled wire 1 is bent and folded directly around the edge of the circuit board 3, and pulled to the back of the solder joint of the circuit board to use or connect components; the fulcrum B is formed at the bottom of the circuit board 3, and the fine enameled wire swing section 1' is pulled with B as the fulcrum. out or connect components. When the fine enameled wire 1 is subjected to external forces such as pulling force, swinging up and down, twisting, etc., it avoids direct action on the point A intersecting with the solder joint 2, thereby effectively protecting the welding of the fine enameled wire and the circuit board, and preventing the wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com