Flux-cored silver filler metal with good liquidity

A technology of silver solder and fluidity, applied in manufacturing tools, welding/cutting medium/material, welding medium, etc., can solve the problems of easy sticking on rollers, low plasticity and strength of silver solder, difficulty, etc. , to achieve the effect of improving moisture absorption and fluidity, avoiding wire breakage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

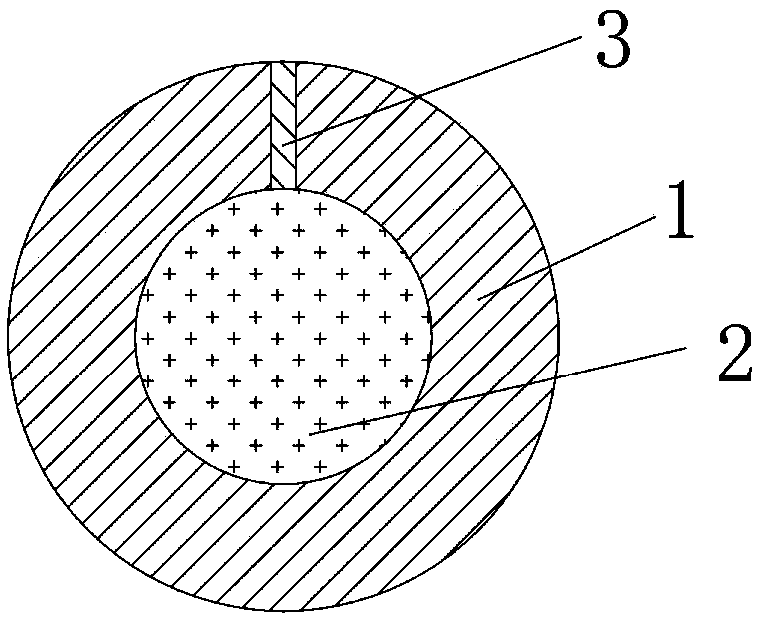

[0025] Such as figure 1 Shown, a kind of flux-cored silver solder with good fluidity comprises the silver solder ribbon of flux powder and coating flux powder, and described silver solder ribbon is BAg30CuZnSn silver solder ribbon, BAg30CuZnSn silver solder ribbon The mass ratio of each component of the flux meets the model requirements of BAg30CuZnSn in GB / T10046-2018 "Silver Solder", the mass of the flux powder accounts for 15% of the total mass, and the mass of each component of the flux powder The ratio is: Potassium hexafluoroborate K 3 BF 6 30%, 5% potassium fluoride, 20% boric acid, 32% boron oxide, 2% sodium carbonate, 0.5% potassium silicate, and the balance is potassium tetrafluoroborate KBF 4 .

[0026] The preparation process of above-mentioned flux-cored silver solder is:

[0027] Step (1), take the BAg30CuZnSn silver solder strip with 4mm width and 0.5mm thickness, and anneal it; step (2), after the annealing treatment is completed, roll the silver solder str...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of flux-cored silver solder with good fluidity comprises the silver solder ribbon of flux powder and coating flux powder, and described silver solder ribbon is BAg30CuZnSn silver solder ribbon, BAg30CuZnSn silver solder ribbon The mass ratio of each component of the flux meets the model requirements of BAg30CuZnSn in GB / T10046-2018 "Silver Solder", the mass of the flux powder accounts for 30% of the total mass, and the mass of each component of the flux powder The ratio is: Potassium hexafluoroborate K 3 BF 6 35%, potassium fluoride 2%, boric acid 25%, boron oxide 30%, sodium carbonate 6%, potassium silicate 1.5%, and the balance potassium tetrafluoroborate KBF 4 .

[0030] The preparation process of above-mentioned flux-cored silver solder is:

[0031] Step (1), take the BAg30CuZnSn silver solder strip with 8mm width and 0.2mm thickness, and anneal it; step (2), after the annealing treatment is completed, roll the silver solder strip ...

Embodiment 3

[0033] Such as figure 1 Shown, a kind of flux-cored silver solder with good fluidity comprises the silver solder ribbon of flux powder and coating flux powder, and described silver solder ribbon is BAg30CuZnSn silver solder ribbon, BAg30CuZnSn silver solder ribbon The mass ratio of each component of the flux meets the model requirements of BAg30CuZnSn in GB / T10046-2018 "Silver Solder", the mass of the flux powder accounts for 23% of the total mass, and the mass of each component of the flux powder The ratio is: Potassium hexafluoroborate K 3 BF 6 33% for potassium fluoride, 3.5% for potassium fluoride, 22% for boric acid, 31% for boron oxide, 4% for sodium carbonate, 1% for potassium silicate, and the balance is potassium tetrafluoroborate KBF 4 .

[0034] The preparation process of above-mentioned flux-cored silver solder is:

[0035] Step (1), take the BAg30CuZnSn silver solder strip with a width of 6mm and a thickness of 3.5mm, and anneal it; step (2), after the annealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com