Reverse-osmosis seawater desalination pretreatment method and device for polluted sea areas

A technology of pretreatment and membrane placement, which is applied in the field of water treatment to achieve the effects of ensuring stability, preventing broken wires, and reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This test uses seawater a in a sea area, and the water quality is shown in Table 1.

[0032] Table 1 Raw water quality table

[0033] indicators

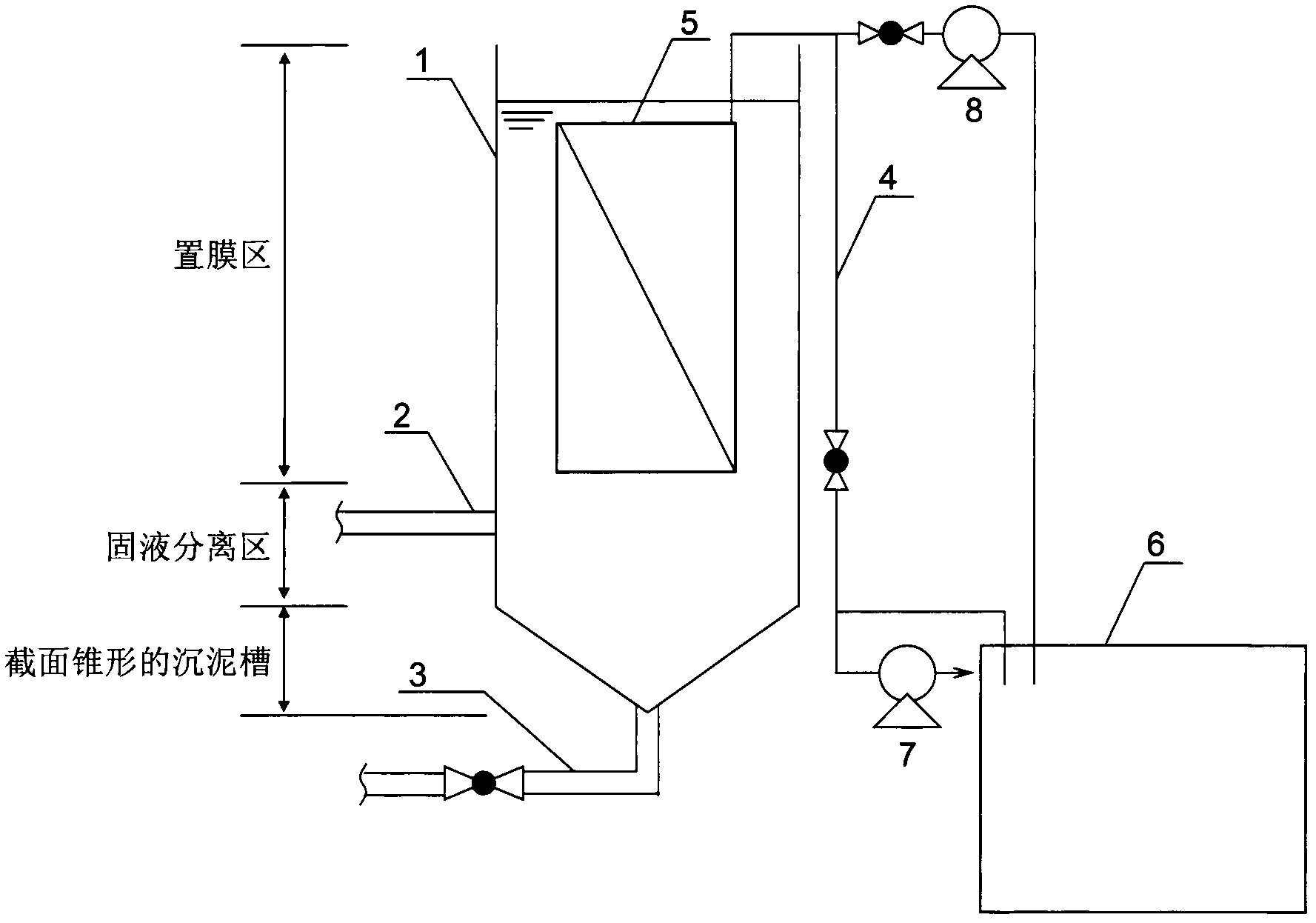

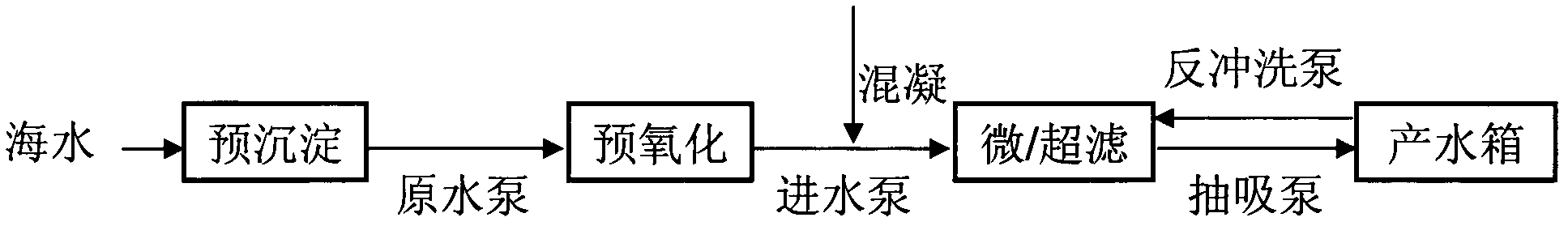

[0034] It can be seen from Table 1 that the raw water quality belongs to Class III water body, and the water body is polluted, and there are many particulate matter in it. The operating process of the system is pre-sedimentation-potassium ferrate oxidation-on-line coagulation-submerged ultrafiltration, in which the submerged ultrafiltration membrane is a hollow fiber ultrafiltration membrane, the membrane material is polyvinylidene fluoride, and the membrane pore size is 0.01 micron. The dosage of potassium ferrate is 1mg / L, and the dosage of coagulant ferric chloride is 2mg / L (calculated as iron). For the submerged membrane tank with tapered groove, in the cross-sectional height of the tank body, the height ratio of the sedimentation tank, the solid-liquid separation area and the membrane installation area is: 4:1...

Embodiment 2

[0036]This test uses seawater b in a sea area, and the water quality is shown in Table 2.

[0037] Table 2 Raw water quality table

[0038] indicators

[0039] It can be seen from Table 2 that the raw water quality belongs to Class III water body, and the water body is polluted. The operating process of the system is pre-sedimentation-potassium permanganate oxidation-on-line coagulation-submerged ultrafiltration, in which the submerged ultrafiltration membrane is a hollow fiber ultrafiltration membrane, the membrane material is polyvinylidene fluoride, and the membrane pore size is 0.01 micron. The dosage of potassium permanganate is 1mg / L, and the dosage of coagulant ferric chloride is 1mg / L (calculated as iron). For the submerged membrane pool with tapered groove, the height ratio of the sedimentation tank, the solid-liquid separation area and the membrane area is 5:1:1.1 in the cross-sectional height of the pool body. The operating conditions of the membrane are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com