Compound-type metal roof thermal-insulation waterproof coating and preparing method thereof

A technology for metal roofing and waterproof coatings, applied in antifouling/underwater coatings, reflection/signal coatings, coatings, etc., can solve problems such as limited life, easy aging, and weak bonding between waterproof materials and metal substrates. Achieve the effect of improving service life, obvious heat insulation effect and good anti-exposure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

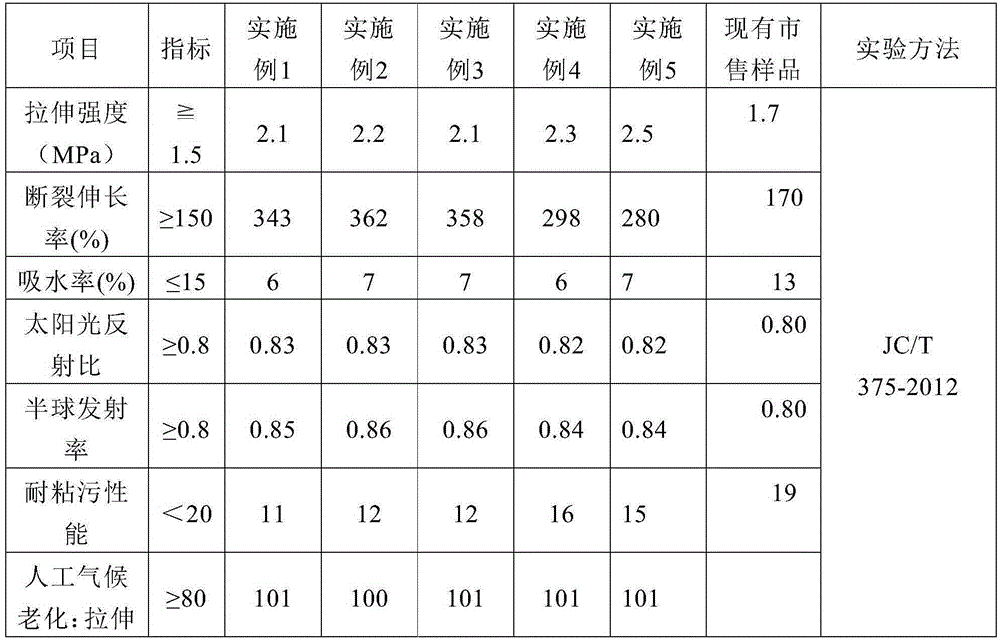

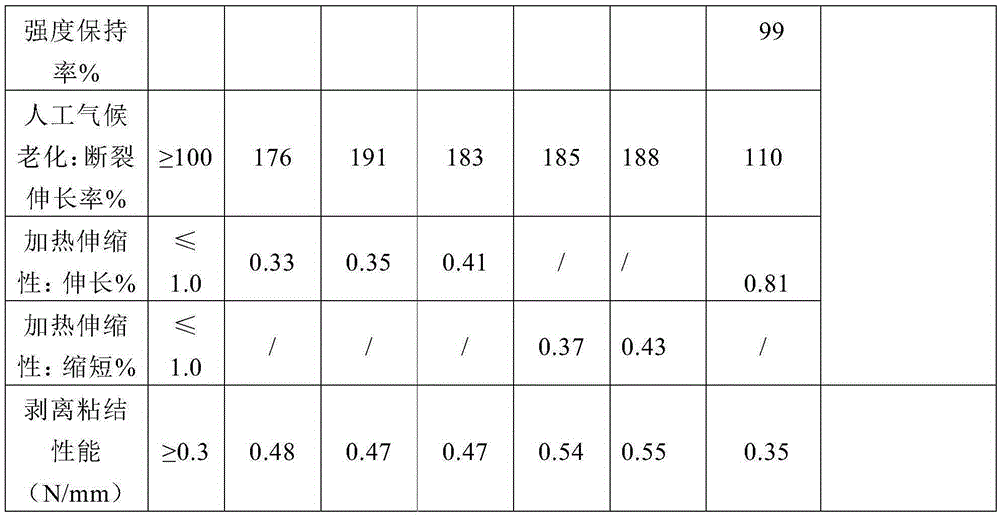

Examples

Embodiment 1

[0044] 1. Preparation equipment

[0045] Speed regulating dispersing machine, mixing tank

[0046] 2. Process description

[0047] According to the formula, it is formed by adding and dispersing according to the sequence requirements of the conventional technical means in the field.

[0048] 3. Formula weight ratio components

[0049] 5-10 parts of water, 0.5-1.5 parts of dispersant, 0.2-1 part of defoamer, 5-15 parts of pigment, 5-10 parts of hollow glass microspheres, 5-10 parts of inorganic thixotropic thickener, 20 parts of inorganic filler -25 parts, 5-43 parts of silicon-modified acrylic emulsion, 28-43 parts of acrylic emulsion, 0.5-1 part of film-forming aid, 0.05-0.1 part of pH regulator, 0.02-0.05 part of thickener, 0.5 part of antifreeze -1 copy.

[0050] Furthermore, the metal roof surface thermal insulation coating also includes 0.1-1 part of anti-aging agent, 0.15-1 part of leveling agent, and 0.2-1 part of fungicide.

[0051] Provide below the prescriptio...

Embodiment 2

[0057] Metal roof base heat dissipation coating of the present invention adopts following method to prepare:

[0058] 1. Preparation equipment

[0059] Speed regulating dispersing machine, mixing tank

[0060] 2. Process description

[0061] According to the formula, it is formed by adding and dispersing according to the sequence requirements of the conventional technical means in the field.

[0062] 3. Formula weight ratio components

[0063] 5-10 parts of water, 0.5-1.5 parts of dispersant, 0.2-1 part of defoamer, 5-10 parts of pigment, 18-27 parts of thermal conductive functional filler, 5-10 parts of inorganic thixotropic thickener, 8-12 parts of inorganic filler 5-40 parts of silicon-modified acrylic emulsion, 25-40 parts of acrylic emulsion, 0.05-0.1 part of pH regulator, 0.02-0.05 part of thickener, 0.5-1 part of antifreeze.

[0064] Furthermore, the heat-dissipating coating for metal roof bases also includes 0.1-1 part of anti-aging agent, 0.15-1 part of leveling...

Embodiment 3

[0073] A composite metal roof heat-insulating and waterproof coating, which is composed of a surface coating and a base coating.

[0074] The raw materials of the surface coating include the following components in parts by weight: water 5, dispersant 0.5, defoamer 0.2, pigment 5, hollow glass microspheres 5, inorganic thixotropic thickener 5, inorganic filler 20, silicon modified 16 parts of acrylic emulsion, 28 parts of acrylic emulsion, 0.5 of film-forming aid, 0.05 of pH regulator, 0.02 of thickener, and 0.5 of antifreeze;

[0075] The raw materials of the base coating include the following components in parts by weight: water 5, dispersant 0.5, defoamer 0.2, pigment 5, thermal conductive functional filler 18, inorganic thixotropic thickener 5, inorganic filler 8, silicon-modified acrylic emulsion 21 parts, acrylic emulsion 25, pH regulator 0.05, thickener 0.02, antifreeze 0.5.

[0076] Among the above raw materials, the dispersant is an anionic dispersant, the defoamer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com