Lignin composite material and preparation method thereof

A composite material and lignin technology, which is applied in the field of polymer composite materials, can solve the problems of decreased mechanical properties of composite materials, easy decomposition of natural polymer compounds, complex processing process, etc., and achieve the effect of convenient processing and excellent anti-ultraviolet ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

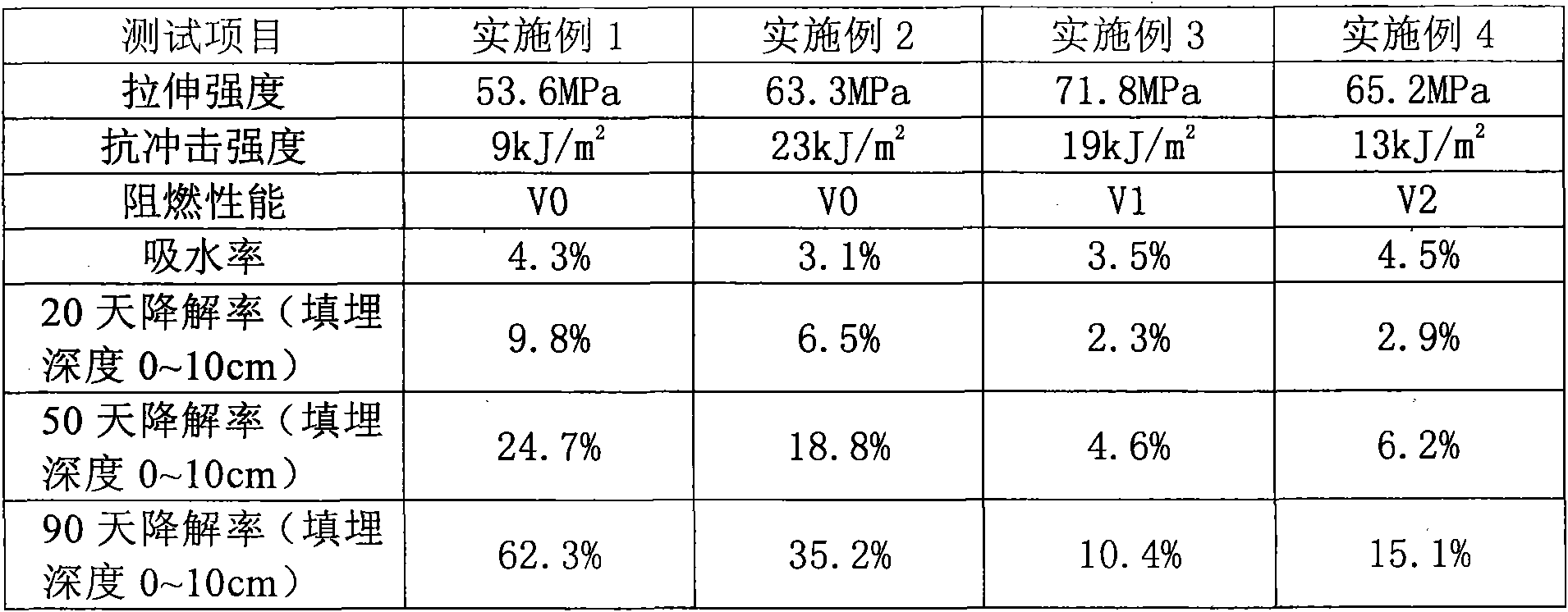

Embodiment 1

[0025] Embodiment 1 of the present invention proposes a kind of lignin composite material, and this lignin composite material is made of high purity ash lignin, polymer compound, fibrous substance, chitin, plasticizer, compatibilizer, antioxidant, flame retardant The polymer compound is made of polylactic acid and polybutylene succinate, the fiber material is bamboo fiber, the plasticizer is glycerin, the compatibilizer is polyhydroxyalkanoate, and the antioxidant is four (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, and triphenyl phosphite as flame retardant.

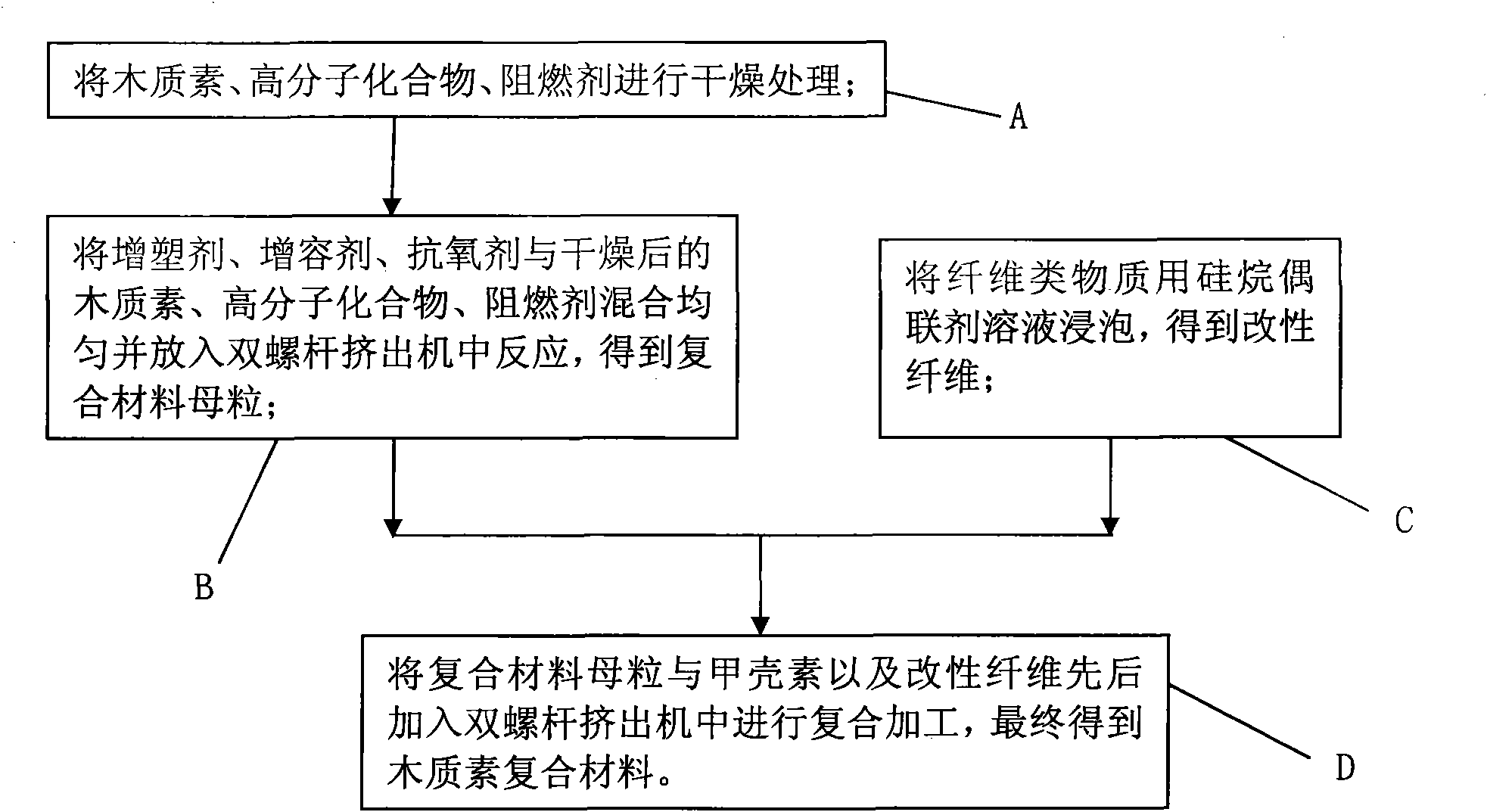

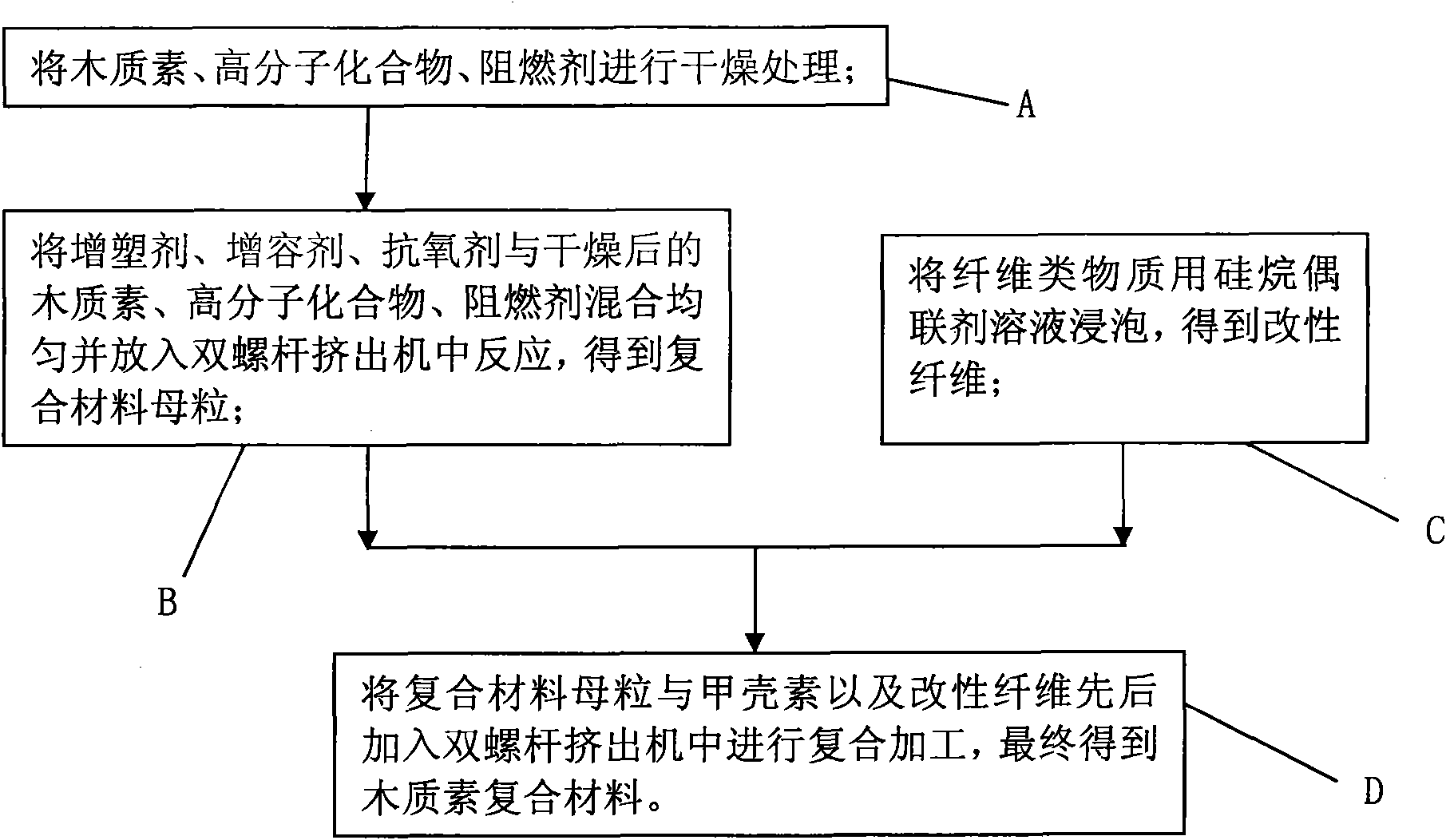

[0026] Specifically, the preparation method of the lignin composite material proposed in Embodiment 1 of the present invention is as follows:

[0027] A: Dry high-purity lignin, polylactic acid, polybutylene succinate, and flame retardant triphenyl phosphite at 50°C for 12 hours to remove moisture;

[0028] B: The high-purity alkali lignin, polylactic acid, polybutylene succinate, flame ret...

Embodiment 2

[0036] Embodiment 2 of the present invention proposes a lignin composite material, which is mixed with lignin, polymer compound, fiber substance, chitin, plasticizer, compatibilizer, antioxidant and flame retardant Among them, the polymer compound is made of polypropylene and polybutyrate, the fiber material is made of jute fiber, the plasticizer is made of glycerin, the compatibilizer is made of polycaprolactone, and the antioxidant is made of four (β-(3,5 Di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, flame retardant adopts antimony trioxide.

[0037]Specifically, the preparation method of the lignin composite material proposed in Embodiment 2 of the present invention is as follows:

[0038] A: Dry lignin, polylactic acid, polybutylene succinate, and flame retardant antimony trioxide at 60°C for 9 hours to remove moisture;

[0039] B: lignin, polylactic acid, polybutylene succinate, flame retardant antimony trioxide and plasticizer glycerin, compatibilize...

Embodiment 3

[0045] Embodiment 3 of the present invention proposes a lignin composite material, the lignin composite material is mixed by lignin, polymer compound, fiber substance, chitin, plasticizer, compatibilizer, antioxidant and flame retardant The polymer compound is made of polyethylene, the fiber material is made of carbon fiber, the plasticizer is made of diethyl phthalate, the compatibilizer is made of polyethylene-vinyl acetate, and the antioxidant is made of β-(3,5- Di-tert-butyl-4-hydroxyphenyl) cyclohexyl propionate, and trioctyl phosphate as flame retardant. The specific preparation method is as follows:

[0046] A: Dry lignin, polyethylene and flame retardant trioctyl phosphate at 70°C for 6 hours to remove moisture;

[0047] B: Dry lignin, polyethylene, flame retardant trioctyl phosphate, plasticizer diethyl phthalate, compatibilizer polyethylene-vinyl acetate, antioxidant β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) cyclohexyl propionate is mixed uniformly in a high-speed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com