Method of preparing super-hydrophobic coating by compounding waterborne polyurethane and hydrophobic modified inorganic nanoparticles

A technology of inorganic nanoparticles and water-based polyurethane, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult control of micro/nano structure and surface, poor uniformity and reproducibility, and unfavorable large-area film formation. Achieve the effects of easy large-area preparation, low production cost, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

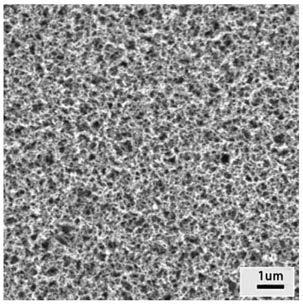

Image

Examples

Embodiment 1

[0048] (1) Preparation of fluorinated titanium dioxide nanoparticles

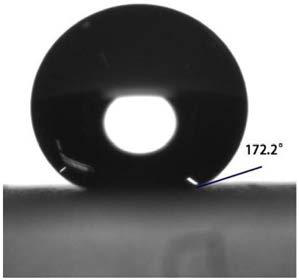

[0049] Add 10mL of absolute ethanol, 0.2mL of high-purity water and 0.15mL of butyl titanate into a 100ml four-neck flask equipped with a thermometer, a magnet, a reflux condenser, and a nitrogen introduction device. After maintaining at room temperature for 6 hours, add 0.1mL of titanium Butyl titanate, keep it for 12 hours, then add 0.1mL of butyl titanate, after 6 hours to obtain a titanium dioxide nanoparticle dispersion with a particle size of 20-70nm and a mass concentration of 3.2%, add 0.3g of fluorine-containing alkyl trialkoxy base silane (that is, the mass of fluorine-containing alkyl trialkoxy silane is 2.7% of the dispersion liquid), and the electromagnetic stirring was turned on at room temperature for 10 hours to obtain a fluorinated titanium dioxide nanoparticle dispersion liquid.

[0050] (2) Preparation of aqueous polyurethane dispersion

[0051] Add 50g of polytetrahydrofuran ether diol ...

Embodiment 2

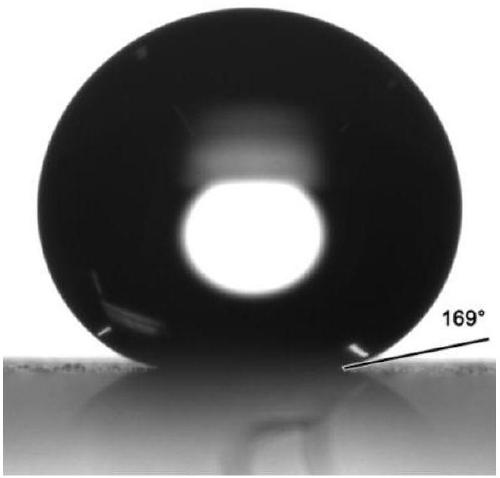

[0058] This embodiment is basically the same as the above-mentioned embodiment 1, except that, when preparing the water-based polyurethane, the polytetrahydrofuran ether diol is replaced with polyester diol, thereby obtaining the polyester-type water-based polyurethane. Such as image 3 It can be seen that the prepared composite coating is a superhydrophobic coating, and the contact angle reaches 169°.

Embodiment 3

[0060] (1) Preparation of fluorinated silica nanoparticles

[0061] Add 80mL of chloroform into a four-necked round-bottom flask, pass nitrogen gas for 30min, add 2g of nano-silica with a particle size of 10-40nm, mechanically stir and reflux, and protect with nitrogen, and obtain silica nanoparticles with a mass concentration of 2.4% after 30min. Add 1.50 g of fluoroalkyltrichlorosilane to the dispersion, and stir at 25°C for 48 hours. Filter under reduced pressure, wash with dried chloroform three times, and dry at 50°C for 24h. Put into 30mL acetone and sonicate for 60min to obtain fluorinated silica nanoparticle dispersion.

[0062] (2) Preparation of aqueous polyurethane dispersion

[0063] Add 50g of polyester diol with a molecular weight of 1638 into a four-neck flask, protect it under nitrogen, heat the reaction system to 80°C to melt, add 16.00g of isophorone diisocyanate, and add 0.4g of dibutyltin dilaurate. After 1 hour of heat preservation, 6.00g of 2,2-dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com