Bamboo fiber and its making process

A manufacturing method and bamboo fiber technology are applied in the directions of fiber processing, fiber raw materials, and fiber raw material processing, etc., which can solve the problems that cannot be used to manufacture clothing fabrics, the softness of bamboo materials is not enough, and the softener contains alkali, etc., and achieves anti-ultraviolet function. Strong, antibacterial, flexibility and improved folding endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

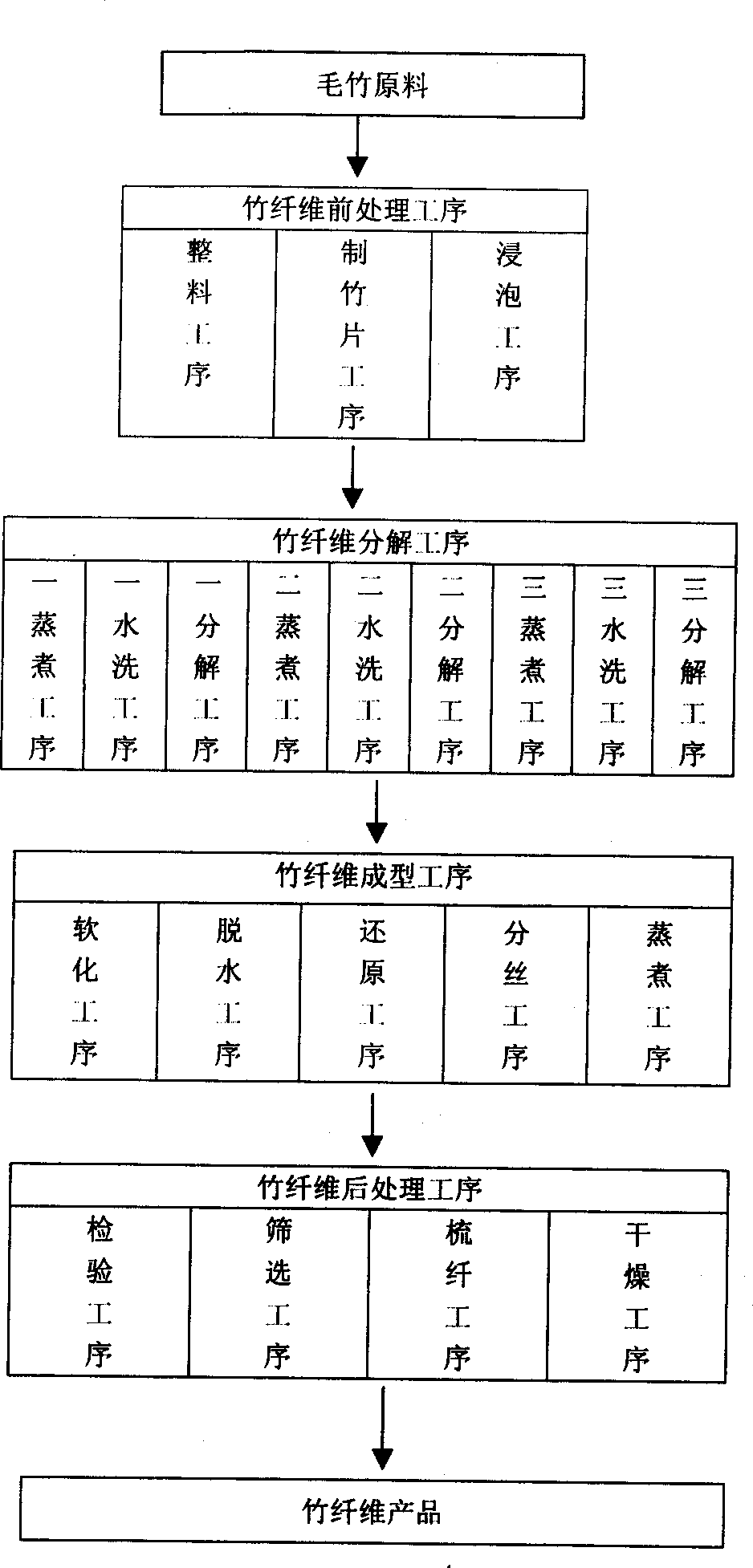

[0009] Embodiment 1: (as shown in Figure 1)

[0010] (1) Whole material process: the raw bamboo is debranched, removed, and sawed into a fixed-length bamboo tube;

[0011] (2) Bamboo chip making process: split the bamboo tube into a width of about 2 cm with a bamboo machine or by hand;

[0012] (3) Soaking process: Soak the bamboo slices in a special degumming softener soaking solution, the proportioning concentration of the degumming softener and water is 30%, and the soaking time is 4 hours. The degumming softener is a natural plant formula and does not contain acid alkaline chemicals;

[0013] (4) A steaming process: heat the bamboo slices soaked in the previous process to 150°C together with the soaking liquid in a cooking pot, pressurize 5 kg / cm2 for 3 hours, and desugar, degrease, and sterilize;

[0014] (5) a water washing process: take out the steamed bamboo slices, and wash the surface soaking liquid with water;

[0015] (6) One-firing process: flatten the bamboo s...

Embodiment 2

[0031] In embodiment 1, the temperature in operation (4) is changed into 80 ℃, pressurized 3 kilograms / square centimeter, time 5 hours, all the other operations are with embodiment 1.

[0032] With the bamboo fiber of the present invention, it is suitable for silk spinning, hemp spinning, cotton spinning, and can also be blended with the above fibers. The thinnest bamboo fiber can reach 48 British branches, and the blended spinning has 80 British branches. Its softness, strength and fit feel are no less than any other fabrics, and the natural characteristics of moso bamboo such as coolness, heat protection, breathability and anti-ultraviolet function are much better than ordinary fabrics, especially at low cost. , It is easy to obtain materials, easy to clean, and quick to dry. Therefore, the present invention will bring a revolution to the world's clothing interface materials, and make the development of the clothing industry have a larger stage. The market of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com