Ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material and preparation method thereof

A thermoplastic elastomer, anti-ultraviolet technology, applied in the field of polymer materials, can solve the problems of TPE materials such as poor anti-ultraviolet ability, flammability, toxicity and irritation, etc., and achieve strong anti-ultraviolet performance, long-lasting effect, flame retardant good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0037] The preparation method of UV-resistant halogen-free flame-retardant TPE material, according to the raw material formula, put the elastomer resin SEBS and naphthenic oil into the mixer and stir at a low speed for 15 minutes, after fully mixing, let it stand for 48 hours to fully swell the elastomer resin SEBS; Put the halogen flame retardant, flame retardant synergist and ultraviolet absorber in a high-speed mixer, and fully stir and mix them at high speed; mix the fully swollen elastomer resin SEBS and the halogen-free flame retardant after mixing The UV absorbent and other raw materials are mixed together for 10 minutes, then added to a twin-screw machine, melted and extruded, cooled, granulated, and finally dried to obtain the final product.

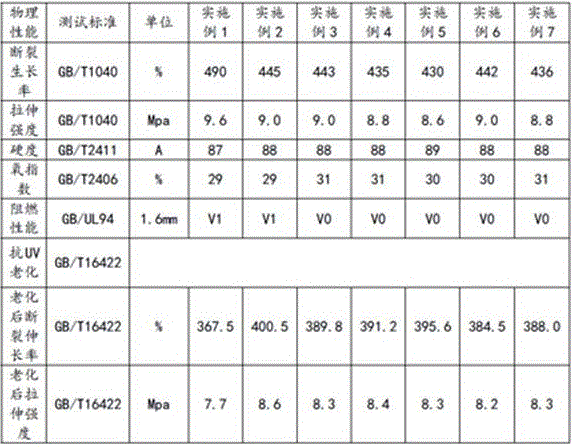

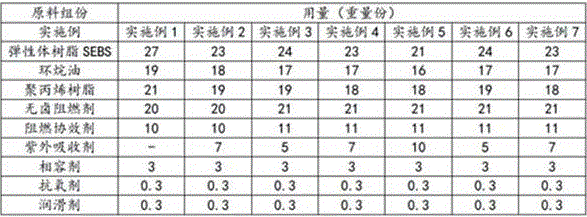

[0038] Table 1: The proportioning of each raw material weight percentage in embodiment 1-7

[0039]

[0040] Wherein, the elastomeric resin SEBS in embodiment 1-7 is the elastomeric resin SEBS 6154 of Taiwan rubber company, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com