Filter nonwoven fabric capable of releasing negative ions

A negative ion and non-woven fabric technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, and spinning solution preparation, can solve the problems of insufficient development and research efforts, and achieve good antibacterial effects and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

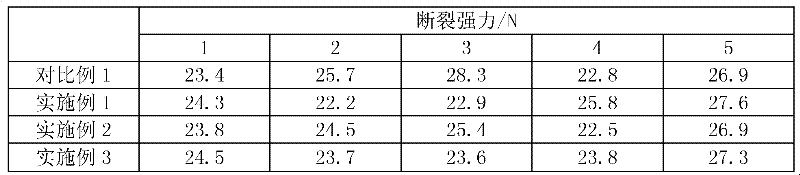

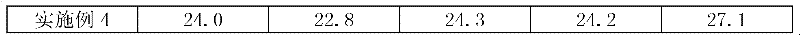

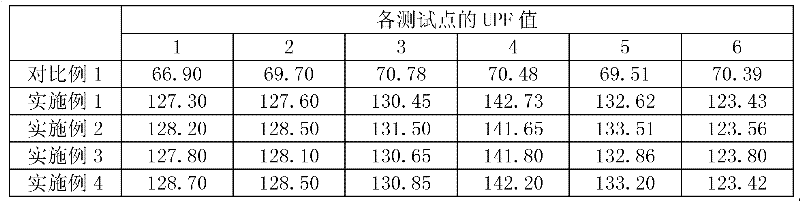

Examples

Embodiment 1

[0022] The step that present embodiment prepares negative ion filter non-woven fabric is as follows:

[0023] a, negative ion ore is pulverized to make nanoscale negative ion powder; said nanoscale negative ion powder comprises tourmaline, opal and magnesium oxide of 10nm, and the mass ratio of said tourmaline, opal and magnesium oxide is 3:1:1.

[0024] b, preparing nano-zinc oxide;

[0025] c. Prepare materials according to the following components and weight percentages:

[0026] Isopropanol 70%;

[0027] Deionized water 10%;

[0028] Polyethylene-vinyl alcohol 10%;

[0029] Carbon fiber 5%;

[0030] Nano Zinc Oxide 2%;

[0031] Nanoscale negative ion powder 3%;

[0032] c. Mix and stir isopropanol and deionized water in proportion, then add polyethylene-vinyl alcohol, heat and stir until polyethylene-vinyl alcohol is completely dissolved;

[0033] d. Then add carbon fiber and the prepared nano-zinc oxide and nano-scale negative ion powder, continue heating and stirr...

Embodiment 2

[0036] The present embodiment is the same as embodiment 1, the difference is:

[0037] In step a, the nanoscale negative ion powder includes 40nm tourmaline, opal and magnesia, and the mass ratio of the tourmaline, opal and magnesia is 5:1:1.

[0038] In the step c, prepare materials according to the following components and weight percent content:

[0039] Isopropanol 58%;

[0040] Deionized water 12%;

[0041] Polyethylene-vinyl alcohol 11%;

[0042] Carbon fiber 4%;

[0043] Nano Zinc Oxide 10%;

Embodiment 3

[0046] The present embodiment is the same as embodiment 1, the difference is:

[0047] In step a, the nanoscale negative ion powder includes 70nm tourmaline, opal and magnesia, and the mass ratio of the tourmaline, opal and magnesia is 7:1:1.

[0048] In the step c, prepare materials according to the following components and weight percent content:

[0049] Isopropanol 55%;

[0050] Deionized water 20%;

[0051] Polyethylene-vinyl alcohol 15%;

[0052] Carbon fiber 3%;

[0053] Nano Zinc Oxide 3%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com