Method for culturing aerobic granular sludge for treating biological nutrients in municipal sewage

A technology for aerobic granular sludge and urban sewage, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Problems such as long start-up time of sludge process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

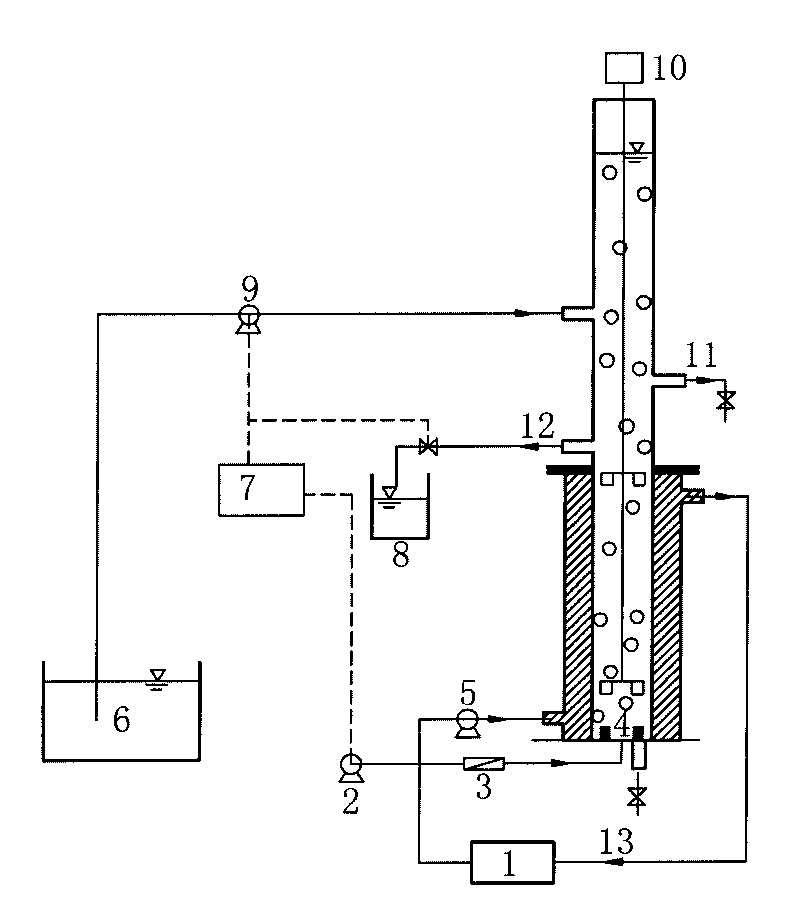

[0023] Such as figure 1 As shown, a sequencing batch SBR reactor with an aspect ratio of 3-12 and a volume exchange rate of 80% is used. The main body of the reactor is a plexiglass cylinder, the effective height of the cylinder is 0.3-1.1m, and the inner diameter of the cylinder is 0.09m , the effective volume is 7L; a group of microporous aeration heads 4 are arranged at the bottom of the reactor, and the ACO electromagnetic air compressor 2 is used to supply air, and the aeration rate is regulated by the rotameter 3, and the reactor is fed with water through the water pump 9, and the The time of each stage of water, anaerobic stirring, aeration, sedimentation, drainage, etc. is set according to the needs of the test, and is automatically controlled by the time controller 7; the water is added through the reservoir 6; the function of the agitator 10 is to make the particles The sludge is in a suspended state by stirring in the anaerobic stage; after sewage treatment, it is d...

Embodiment 2

[0032] This embodiment adopts the aerobic granular sludge obtained in Example 1 as inoculated sludge, figure 1 The shown sequencing batch SBR reactor is used to treat low-carbon source, high-concentration nitrogen and phosphorus wastewater, and investigate the simultaneous denitrification and phosphorus removal ability of the above-mentioned aerobic granular sludge. The main body of the reactor is a plexiglass cylinder, the effective height of the cylinder is 1.1m, the inner diameter of the cylinder is 0.09m, and the effective volume is 7L; the bottom of the reactor is equipped with a group of microporous aeration heads 4, and the ACO electromagnetic air compressor 2 is used The air supply and aeration volume are regulated by the rotameter 3, and the reactor is fed with water through the water inlet pump 9, and the time of each stage of water inlet, aeration, sedimentation, and drainage is set according to the needs of the test, and is automatically realized by the time control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com