Graphene/silver phosphate composite visible light photocatalyst and preparation method thereof

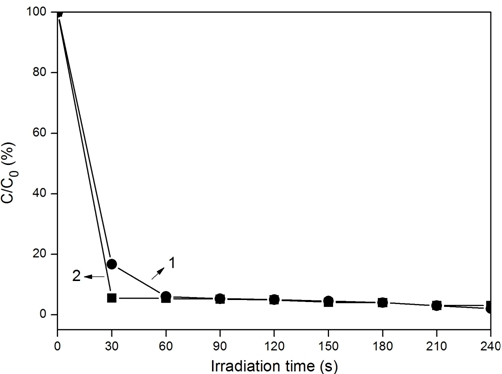

A photocatalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low utilization rate of visible light, low degradation efficiency of high-concentration organic dyes, etc. Large-scale promotion, simple preparation method, and wide response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

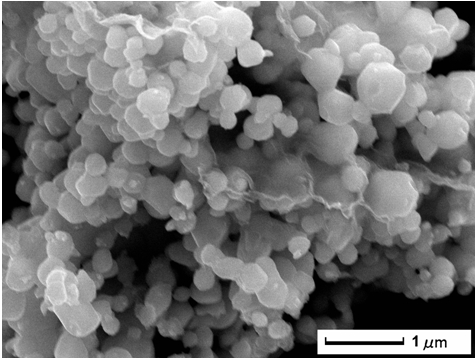

[0027]Take 20 mg of graphene oxide and ultrasonically disperse in 20 mL of deionized water for 3 hours; under the condition of magnetic stirring, dissolve 1.53 g of silver nitrate in 20 mL of deionized water to obtain a silver nitrate solution with a concentration of 0.45 mol / L, and add it dropwise In the above graphene oxide dispersion, continue to stir for 3 hours and then age for 12 hours to obtain a mixed precursor solution A; dissolve 0.43 g of disodium hydrogen phosphate in 20 mL of deionized water to obtain a concentration of 0.15 mol / L of disodium hydrogen phosphate solution; under magnetic stirring conditions, add the disodium hydrogen phosphate solution dropwise to the mixed precursor solution A until the reaction system appears brownish-yellow turbid; In the reaction kettle, react at 140° C. for 24 hours, cool to room temperature; filter with suction, wash the precipitate with deionized water and absolute ethanol several times, and dry it in vacuum.

Embodiment 2

[0029] Take 50 mg of graphene oxide and ultrasonically disperse it in 30 mL of deionized water for 3 hours. Under the condition of magnetic stirring, dissolve 1.53 g of silver nitrate in 20 mL of deionized water to obtain a silver nitrate solution with a concentration of 0.45 mol / L, and add it dropwise In the above graphene oxide dispersion, continue to stir for 4 hours and then age for 16 hours; dissolve 0.43 g of disodium hydrogen phosphate in 20 mL of deionized water to obtain a disodium hydrogen phosphate solution with a concentration of 0.15 mol / L; The disodium hydrogen phosphate solution was added dropwise to the graphene oxide / silver nitrate solution until brownish yellow turbidity appeared in the reaction system; after the dropwise addition was completed, the stirring was continued at room temperature for 30 minutes, and the mixed solution was transferred to a hydrothermal reaction kettle for 160 °C for 20 hours, cooled to room temperature; filtered with suction, washed...

Embodiment 3

[0031] Take 100 mg of graphene oxide and ultrasonically disperse it in 30 mL of deionized water for 4 hours. Under the condition of magnetic stirring, dissolve 1.53 g of silver nitrate in 20 mL of deionized water to obtain a silver nitrate solution with a concentration of 0.45 mol / L, and add it dropwise In the above-mentioned graphene oxide dispersion, continue to stir for 5 hours and then age for 20 h; dissolve 0.43 g of disodium hydrogen phosphate in 20 mL of deionized water to obtain a disodium hydrogen phosphate solution with a concentration of 0.15 mol / L; Add the disodium hydrogen phosphate solution dropwise to the graphene oxide / silver nitrate solution until brownish yellow turbidity appears in the reaction system; after the dropwise addition, continue to stir at room temperature for 40 minutes, transfer the mixed solution to the hydrothermal reaction kettle, 180 °C for 16 hours, cooled to room temperature; filtered with suction, washed the precipitate with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com