Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

A composite material and nano-composite technology, which is applied in the field of preparation of heat-resistant aluminum-based materials technology, can solve the problems of difficulty in mastering, limited nano-enhanced phase dispersion ability, high energy consumption, etc., and achieves simple and easy preparation process and easy equipment requirements The effect of mastering and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

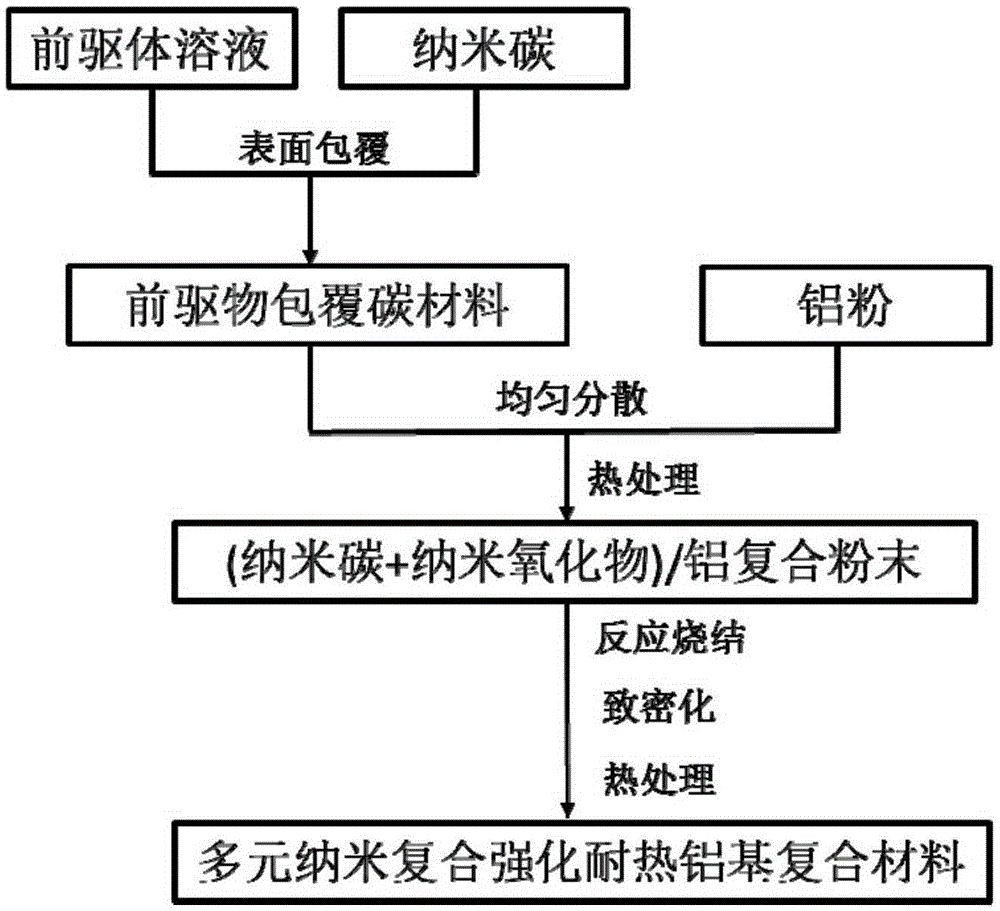

Method used

Image

Examples

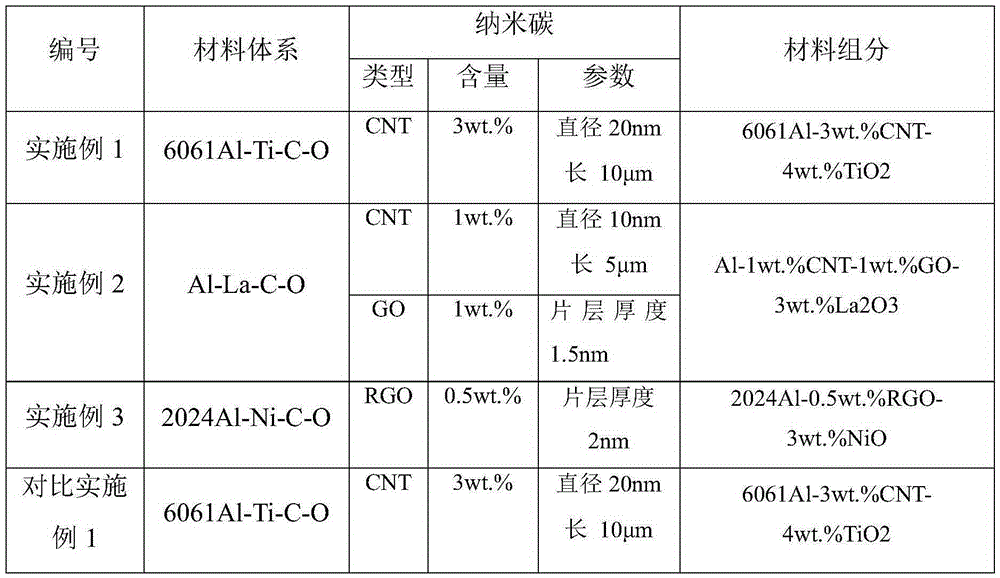

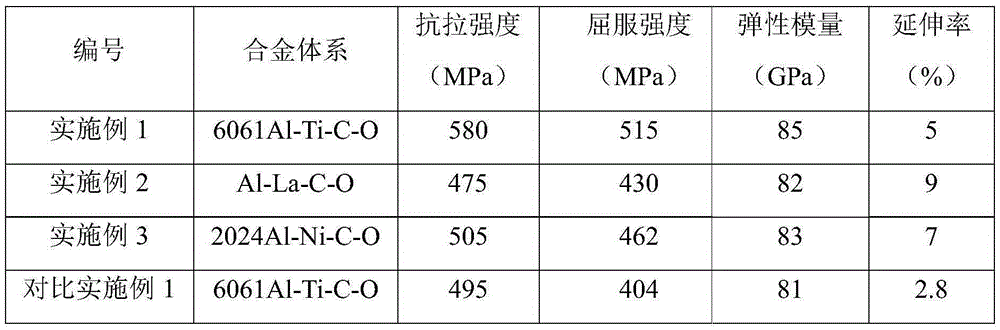

Embodiment 1

[0046] 6mlTiCl 4 12g of citric acid and 10ml of ethylene glycol were dissolved in 40ml of alcohol, and magnetically stirred to fully dissolve to obtain a precursor solution; 3g of carbon nanotubes were sonicated in 400ml of alcohol for 1 hour to form a dispersed carbon nanotube dispersion. Add the precursor solution dropwise to the carbon nanotube dispersion, and continue ultrasonication for 1h to coat the precursor on the surface of the carbon nanotube, add 93g of aluminum powder to the dispersion, stir magnetically for 0.5h, and then filter and dry to obtain the precursor- Carbon nanotube-aluminum composite powder. Then put the precursor-carbon nanotube-aluminum composite powder into the N 2 Heating to 230°C in a tube furnace under atmosphere protection for 1h reaction, and then heating to 600°C for 0.5h to remove residual organic matter on the surface to obtain nano-titanium oxide-carbon nanotube-aluminum composite powder. The nano-titanium oxide-carbon nanotube-aluminum ...

Embodiment 2

[0048] 9gLa 2 Cl 3 ·5H 2 O and 5g of polyvinylpyrrolidone were dissolved in 20ml of water, and magnetically stirred to make them fully dissolved to obtain a precursor solution; respectively, 1g of carbon nanotubes and 1g of graphene were sonicated in 200ml of water for 1h to form a dispersed carbon nanotube dispersion. Add half of the mass of the precursor solution to the carbon nanotube dispersion and the graphene dispersion respectively, and continue to sonicate for 1 hour to coat the precursor on the surface of the carbon nanotube and graphene, and then filter and dry to obtain the precursor - Carbon nanotube composite powder. Put the precursor-carbon nanotube composite powder into the N 2 Heating to 600° C. for 2 hours in a tube furnace under atmosphere protection to obtain nanometer lanthanum oxide-carbon nanotube composite powder. After mixing the nano-lanthanum oxide-carbon nanotube composite powder with 93g of aluminum powder, ball milled in a planetary ball mill f...

Embodiment 3

[0050] 12gNiCl 2 ·6H 2 O and 20g of glucose were dissolved in 20ml of water, and magnetically stirred to fully dissolve it to obtain a precursor solution; 0.5g of graphene oxide was ultrasonicated in 200ml of water for 1 hour to form a graphene oxide dispersion. Add the precursor solution dropwise to the graphene oxide dispersion, and continue ultrasonication for 1 h to coat the precursor on the graphene oxide surface. Put 96.5g of 2024 aluminum alloy powder in 200ml of water for magnetic stirring, and slowly add graphene oxide dispersion liquid dropwise, then vigorously stir the solution, add 8g of sodium borohydride, and then carry out suction filtration and drying to obtain nano-nickel-graphene oxide-aluminum composite powder. The nano-nickel-graphene oxide-aluminum composite powder was cold-pressed into an ingot with a diameter of 40 mm in a steel mold and then heated at 600 °C and N 2 Sintering under atmosphere for 2h. During the sintering process, the nano-nickel rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com