3D printing raw material and 3D printing method and 3D printing workpiece adopting same

A 3D printing and raw material technology, applied in the field of 3D molding, can solve the problems of long printing time, unfavorable fiber mechanical properties, increase equipment utilization time and manufacturing cost, etc., achieve the increase of printing single layer thickness, increase printing speed, and ensure mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The printed structure obtained by printing the bonded block unit

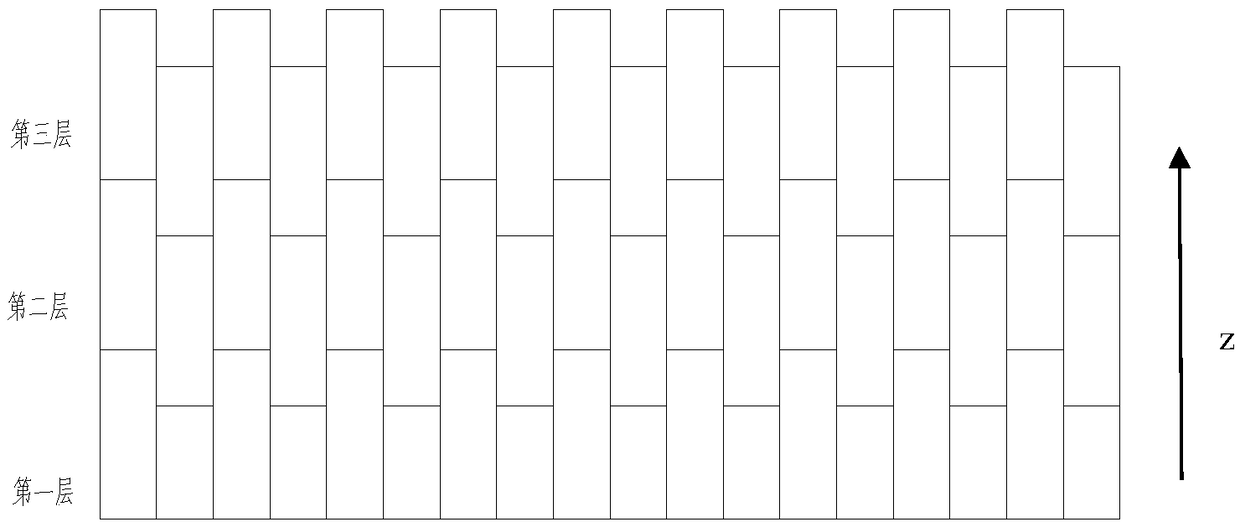

[0064] figure 1 It shows a three-layer printing structure formed by printing with bonded block units. The block unit has a fiber content of 65%v, a size of 5mm×5mm×10mm, and a fiber content of 65%v, and a size of 5mm×5mm×15mm. The materials are carbon fiber reinforced PA6 with smooth surface and coated with epoxy quick-drying adhesive. Printing form: two kinds of blocks are arranged alternately in the first layer, and one kind of block of 5mm×5mm×15mm is used in the next two layers.

[0065] Effect: After using this printing form, on the material, the unit with high fiber content is used to increase the overall fiber content of the block unit; in the printing form, the gaps between the printing layers are alternately staggered, which improves the crack resistance between layers and ensures the Z direction Excellent mechanical properties; in terms of printing speed, the printing speed of the whole body ...

Embodiment 2

[0067] The printed structure obtained by printing the solder block unit

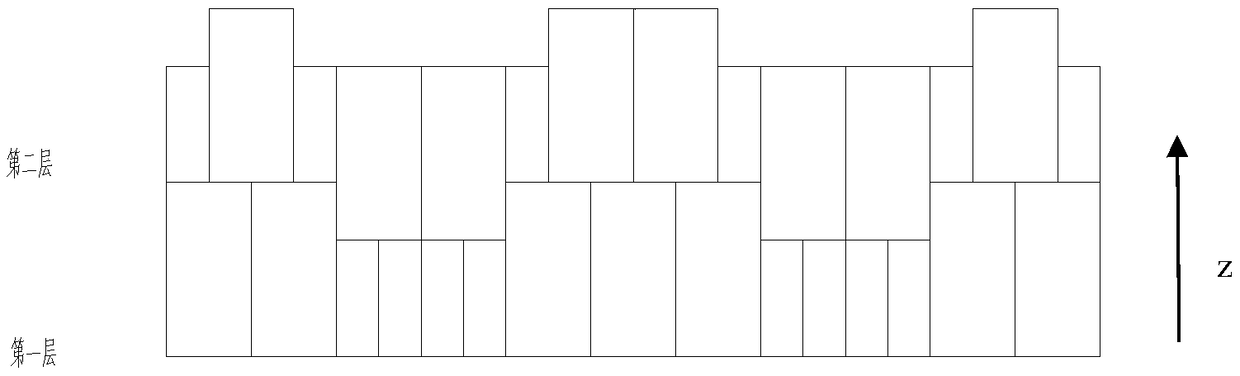

[0068] figure 2 It shows a two-layer printing structure formed by printing with soldered block units. The block unit has a fiber content of 60%v and a size of 10mm×10mm×15mm and a fiber content of 60%v and a size of 5mm×10mm×10mm. The material Both are carbon fiber reinforced PP, and there are multiple welding lines with a height of 0.5mm (adjacent distance: 2mm) on the surface. Printing form: two layers use block units of two sizes and are arranged according to a certain rule.

[0069] Effect: After using this printing form, the fiber content of the printed part is increased to 60% v; the mechanics of the printed part in all directions is improved, and the crack resistance of the part is improved; in terms of printing speed, the printing speed of the whole body is increased to the original 8 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com