Preparation method of controllable volume fraction Ti2AlCp/Al base composite material

A composite material and volume fraction technology, which is applied in the field of aluminum matrix composite materials, can solve the problems of difficult preparation of reinforcement prefabricated blocks, and achieve the effects of controllable reinforcement content, increased hardness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

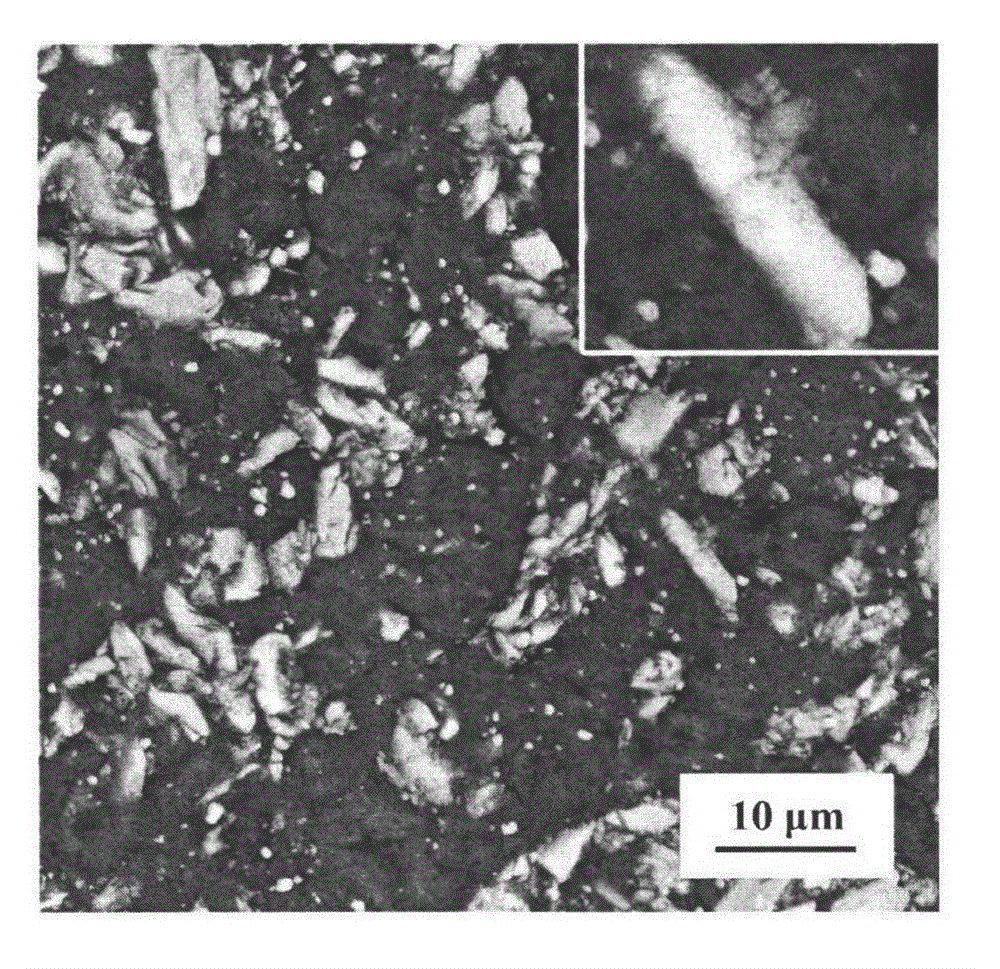

[0026] Ti 2 AlC with 20% Ti by volume 2 AlC p Preparation of Al / Al composites

[0027] Step 1: Calculate the required Ti according to formulas (1) and (2) 2 The quality of AlC powder and Al powder and use the precision balance that precision is 0.1mg to weigh out their quality respectively, carry out 12 hours mechanical mixing with absolute ethanol by weight ratio, then mix The final powder was dried in an electric blast drying oven at a temperature of 70° C. for 15 hours.

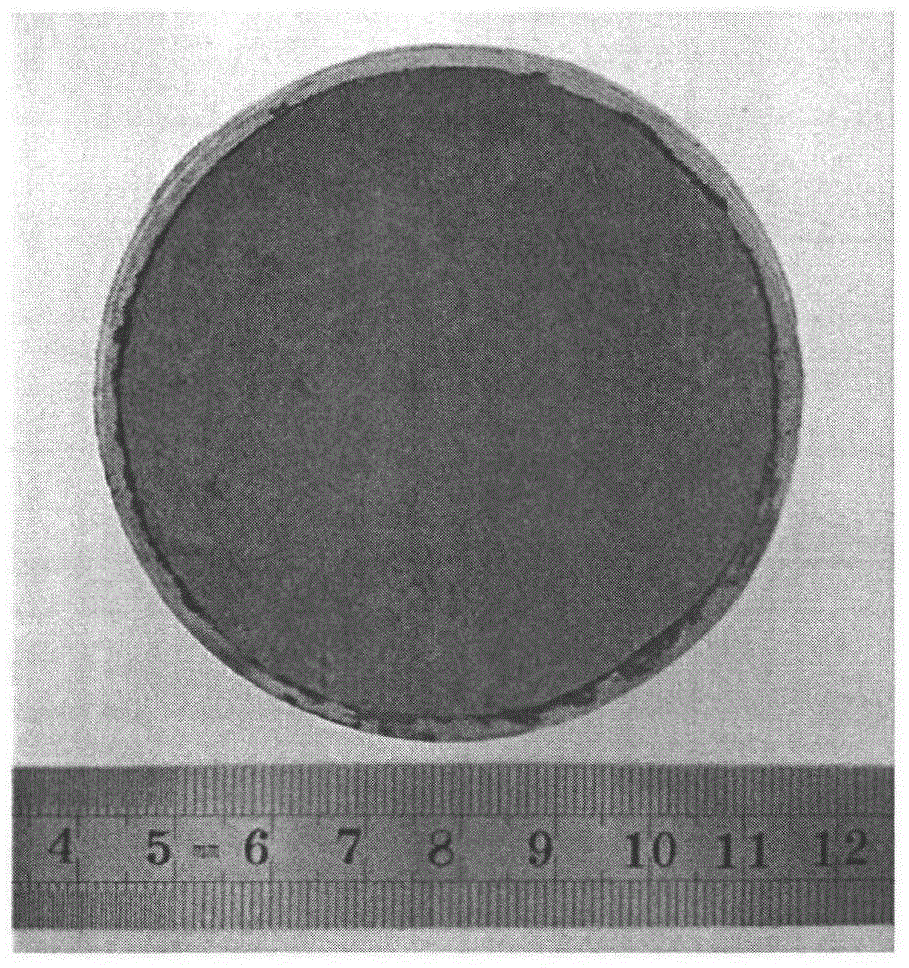

[0028] Step 2: Put the dried mixed powder in a glass beaker, then spray distilled water into the powder raw material, and stir the powder while spraying distilled water until it is in a semi-wet state that is uniform, fluffy and non-agglomerated. Then it is slowly poured into a cylindrical steel mold, and the semi-wet mixed powder is flattened without applying downward pressure, and cold-pressed on a four-column universal hydraulic press. Slowly pressurize when pressing, control the press to slowly pr...

Embodiment 2

[0032] Ti 2 AlC with 45% Ti by volume 2 AlC p Preparation of Al / Al composites

[0033] Step 1: Calculate the required Ti according to formula (1) 2 The quality of the AlC powder was weighed by a precision balance with an accuracy of 0.1 mg.

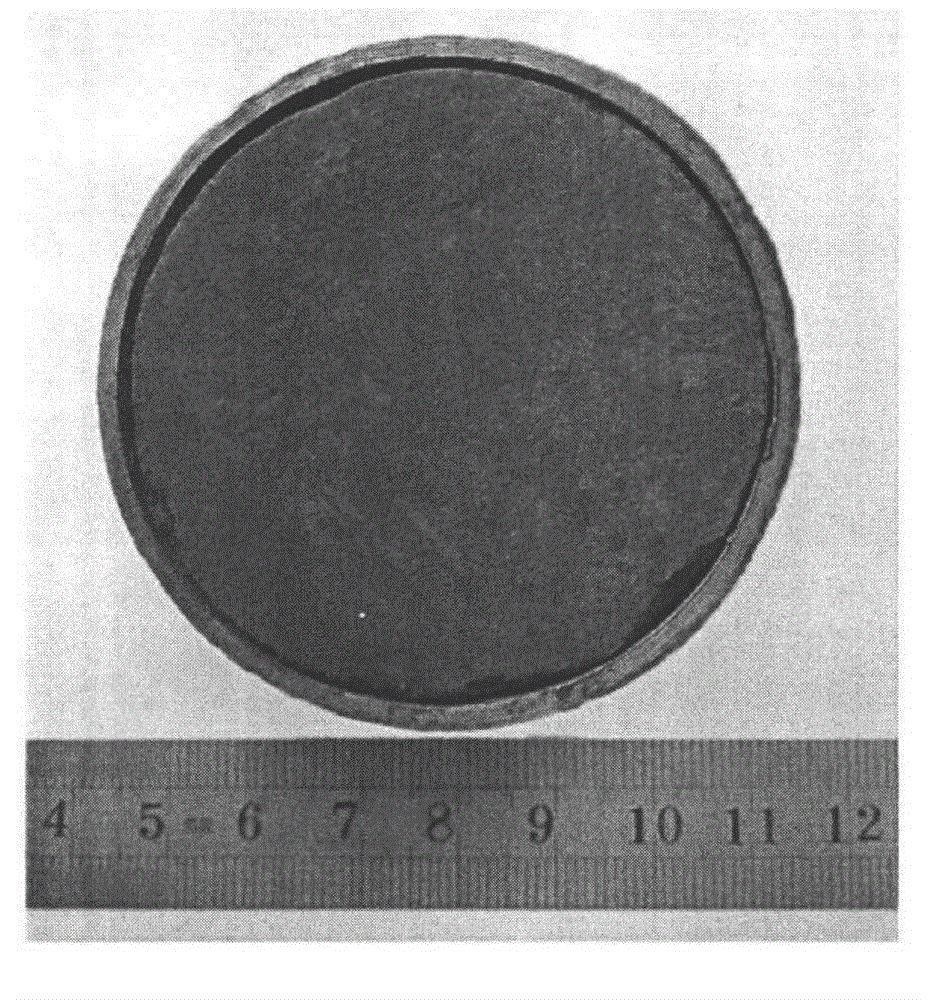

[0034] Step 2: Put the weighed Ti 2AlC powder is placed in a glass beaker, and then distilled water is sprayed into the powder raw material, and the powder is stirred while spraying distilled water until it presents a semi-wet state that is uniform, fluffy and non-agglomerated. Then it is slowly poured into a cylindrical steel mold, and the semi-wet mixed powder is flattened without applying downward pressure, and cold-pressed on a four-column universal hydraulic press. Slowly pressurize when pressing, control the press to slowly press down the mold pressure head to the height h mark of the prefabricated block, no need to hold the pressure, and then slowly demold it and place it in an 80°C electric blast drying oven for 24 hours to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com