Infrared anti-false fiber and its production method and use

An anti-counterfeiting fiber and infrared technology, which is applied in the direction of melt spinning, special patterns, and information-carrying cards, can solve the problems of reducing anti-counterfeiting effect and anti-counterfeiting effect, and achieve good anti-counterfeiting effect, difficult to find, and good concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

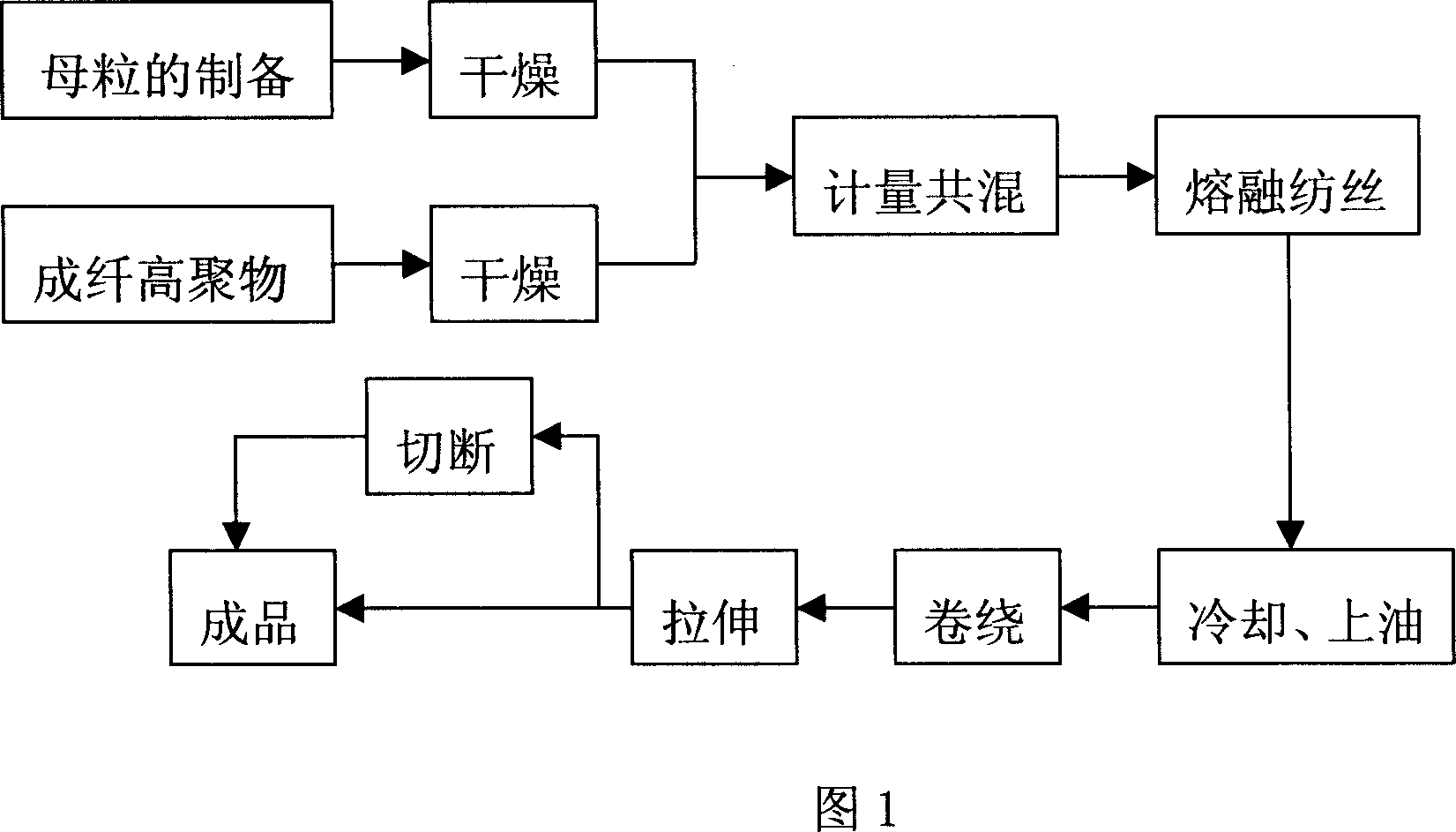

Method used

Image

Examples

Embodiment 1

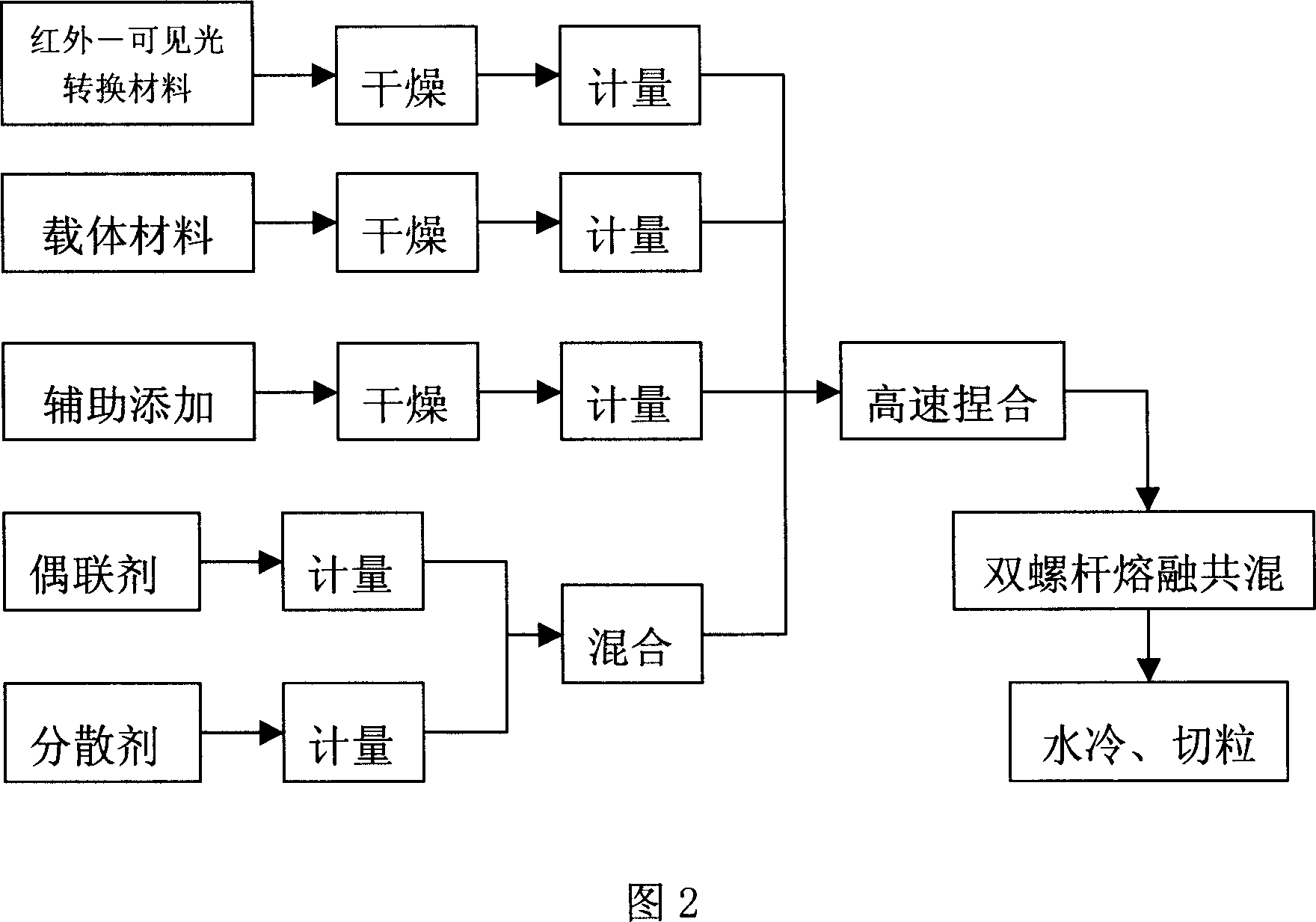

[0028] Polypropylene infrared security fiber

[0029] (1) Preparation of infrared anti-counterfeiting masterbatch: Infrared-visible light up-conversion material (main component is Ba 2 ErCl 7 Rare earth compounds) and auxiliary additives (ultra-high molecular weight polysiloxane with a molecular weight of 2 million) were vacuum-dried respectively, and the dried infrared-visible light up-conversion material and auxiliary additives and polypropylene were kneaded in a kneader. During the kneading process Add coupling agent (titanate coupling agent (NDZ-1011)) and dispersant (white oil), knead evenly, melt blend and extrude by screw extruder, and pelletize after water cooling to obtain polypropylene infrared anti-counterfeiting Masterbatch. Among them, the mass percentage of each component is 40% of infrared-visible light up-conversion material, 56% of carrier material, 0.1% of titanate coupling agent (NDZ-1011), 1% of white oil dispersant, auxiliary additive...

Embodiment 2

[0033] Polyester infrared security fiber

[0034] (1) Preparation of infrared anti-counterfeiting masterbatch: Infrared-visible light up-conversion material (main component is BaLn 2 f 8 Rare earth compound), carrier material (PBT) and auxiliary additive (ultra-high molecular weight polysiloxane with a molecular weight of 2.2 million) were vacuum-dried separately, kneaded in a kneader, and a coupling agent (silane coupling agent was added during the kneading process (KH-550)) and dispersant (paraffin oil), kneaded evenly, melt blended and extruded by screw extruder, and pelletized after water cooling to obtain polyester infrared anti-counterfeiting masterbatch, wherein, the mass percentage of each component The content is 50% of infrared-visible light up-conversion material, 48.8% of carrier material (PBT), 0.8% of silane coupling agent (KH-550), 3% of dispersant paraffin oil, auxiliary additive ultra-high molecular weight polysiloxane (molecular weight 22...

Embodiment 3

[0038] Polyamide 6 infrared anti-counterfeiting fiber

[0039] (1) Preparation of polyamide 6 infrared anti-counterfeiting masterbatch: Infrared-visible light up-conversion material (main component is Ba 2 ErCl 7Rare earth compound), carrier material polyamide 6 and auxiliary additive (ultra-high molecular weight polysiloxane with a molecular weight of 1.8 million) were vacuum-dried respectively, kneaded in a kneader, and a coupling agent (titanate Coupling agent (KH-560)) and dispersant (white oil), kneaded evenly, melt blended and extruded by screw extruder, cooled by water, pelletized to obtain infrared anti-counterfeiting masterbatch. Among them, the mass percentage of each component is infrared-visible light up-conversion material 20%, carrier material polyamide 70%, titanate coupling agent (KH-560) 3%, white oil dispersant 0.1%, ultra-high molecular weight Polysiloxane (molecular weight 1,800,000) auxiliary additive 1%;

[0040] (2) Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com