Swivel base frame for train seats

A technology of rotating pedestals and seats, which is applied to seats, railway car body parts, transportation and packaging, etc., and can solve problems such as complex rotating structures, rotating faults, and easy loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

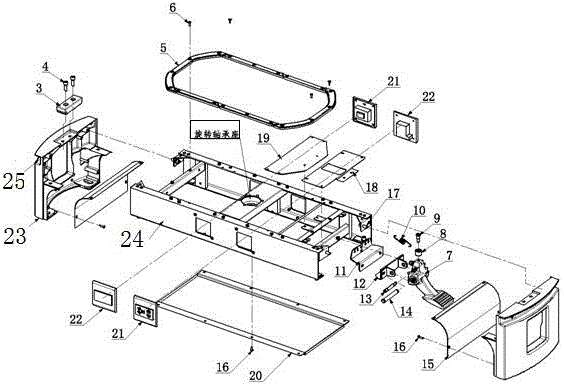

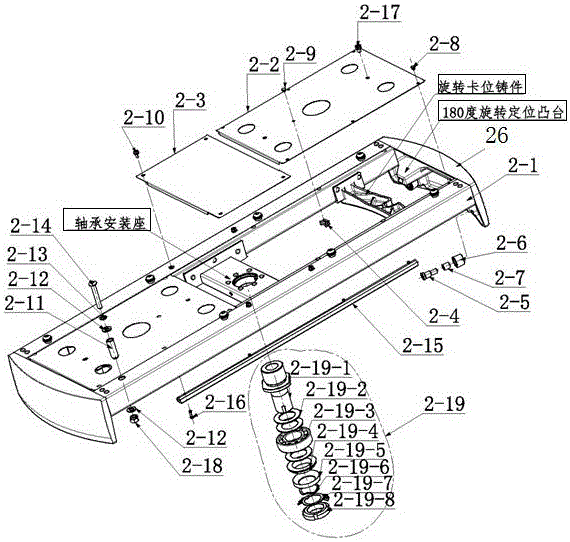

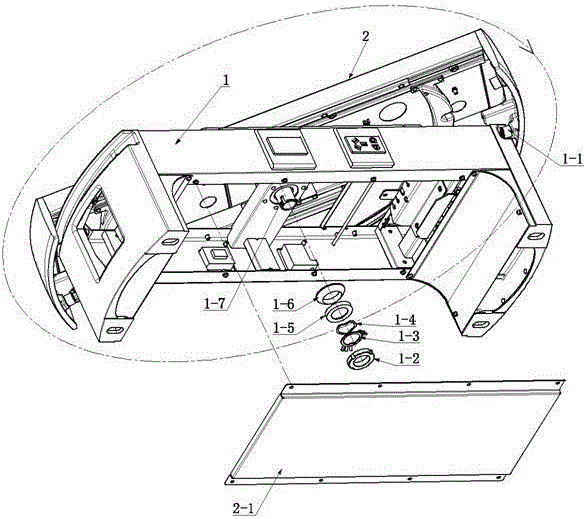

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] 1. Bottom frame mechanism 2. Turn frame mechanism 3. Limiting block 4. M8 screw 5. Rotary slider group 6. M4 cross pan head screw 7. Side steps 8. Roller 9. Bottom frame step bolt 10. Small pull Spring 11. Cable mounting plate 12. Pedal mounting bracket 13. First connecting shaft 14. Second connecting shaft 15. Leg sealing plate 16. M4 cross round head screw 17. M8 combination bolt 18. First cover plate 19. Second Second cover plate 20. Fireproof board 21. British socket 22. Chinese socket 23. Chair leg 24. Base frame welding riveting assembly 25. Rotation guide groove 26. Anti-rollover casting 2-1. Rotary frame riveting assembly 2-2. The first sealing plate 2-3. The second sealing plate 2-4. The tie seat 2-5. The step bolt of the turntable 2-6. The guide roller 2-8. The blind rivet 2-9. The blind rivet 2-10 .Hex screw 2-11. Support tube 2-12. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com