Microchannel heat exchange plate with V-shaped fractal structures and preparation method of microchannel heat exchange plate

A fractal structure and microchannel technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of single structure of heat exchange plate and small specific surface area, so as to increase the number of vaporization cores and enhance the vaporization process , The effect of improving the heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking red copper as the sheet material for processing the heat exchange plate, and the second-order V-shaped fractal microchannel as an example, the process is as follows:

[0033] (1) Preliminary processing of raw materials. First, remove the burr from the 50×100×3mm sheet, then fix it on the fixture, install it on the BC6063B planer vise, and use the dial indicator to level the surface of the sheet.

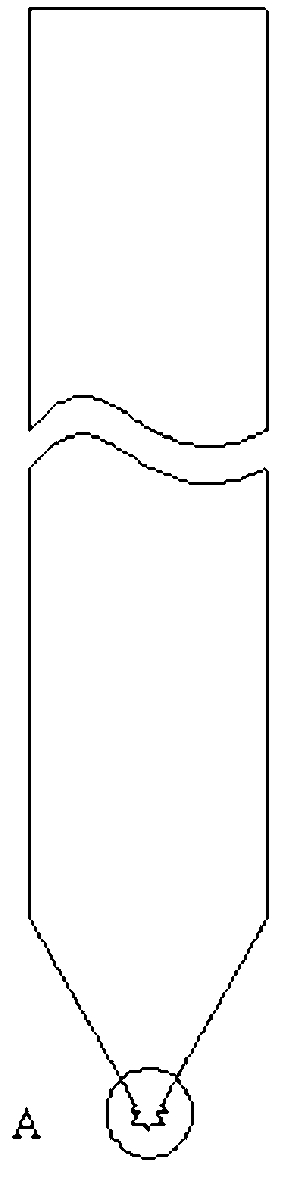

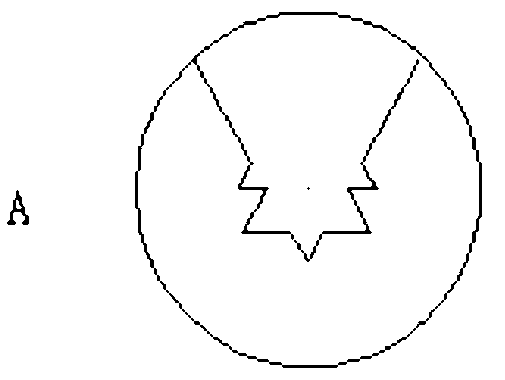

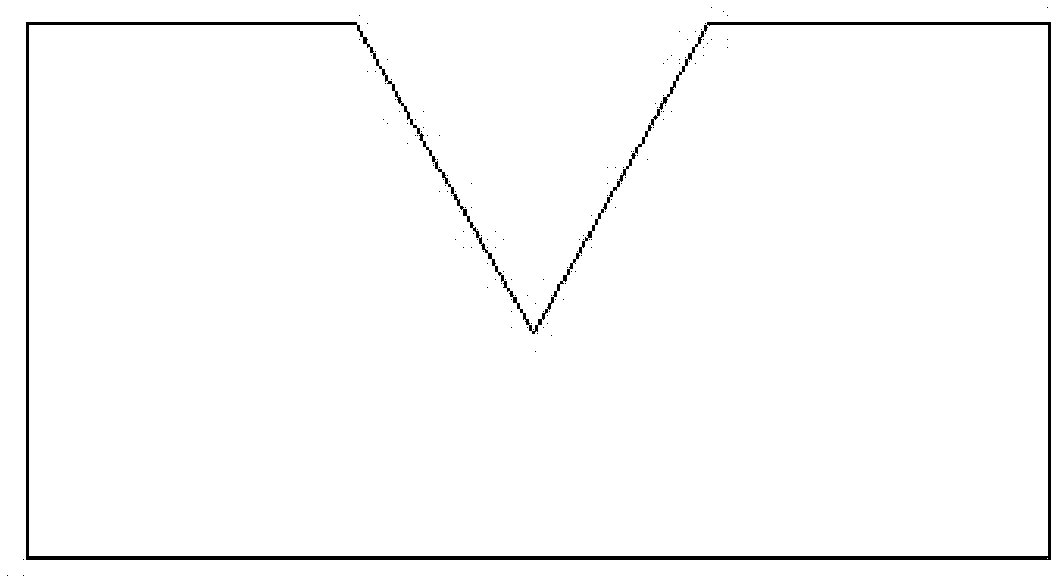

[0034] (2) Tool clamping. The selected multi-stage composite fractal plow cutting tool is installed on the tool holder, and the verticality corrector is used to ensure that the angle between the tool and the surface of the sheet to be processed is 90°. The material of the tool is high-speed steel, and the shape of the cutting edge is controlled by the trajectory of the wire-cut molybdenum wire, so that it has a 3-order V-shaped fractal structure, such as figure 1 , figure 2 shown. Taking the two-stage composite plow cutting tool as an example, the depth of the firs...

Embodiment 2

[0038] Taking red copper as the sheet material for processing the heat exchange plate, and the second-order V-shaped fractal microchannel as an example, the process is as follows:

[0039] (1) Preliminary processing of raw materials. First remove the burrs from the 50×100×15mm sheet, then install it on the BC6063B planer, use the planer to plan the surface to be processed, turn the sheet 180° after completion, and continue to process the other side with the planer , to ensure the parallelism and flatness of the two planes.

[0040] (2) Tool clamping. The selected multi-stage composite fractal plow cutting tool is installed on the tool holder, and the verticality corrector is used to ensure that the angle between the tool and the surface of the sheet to be processed is 90°. The cutting tool material is high-speed steel, and the cutting edge shape is controlled by wire cutting molybdenum wire track 1, so that it has a V-shaped fractal structure, such as figure 1 , figure 2A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com