Method for improving conductive heat stability of polyaniline/inorganic nano conductive composite material

A conductive composite material, inorganic nanotechnology, applied in the direction of organic material conductors, non-metallic conductors, etc., can solve the problems of high production cost, poor electrical conductivity of polyaniline, large amount of long-chain organic protonic acid doping, etc., to improve dispersion performance, improve electrical conductivity and thermal stability, and reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

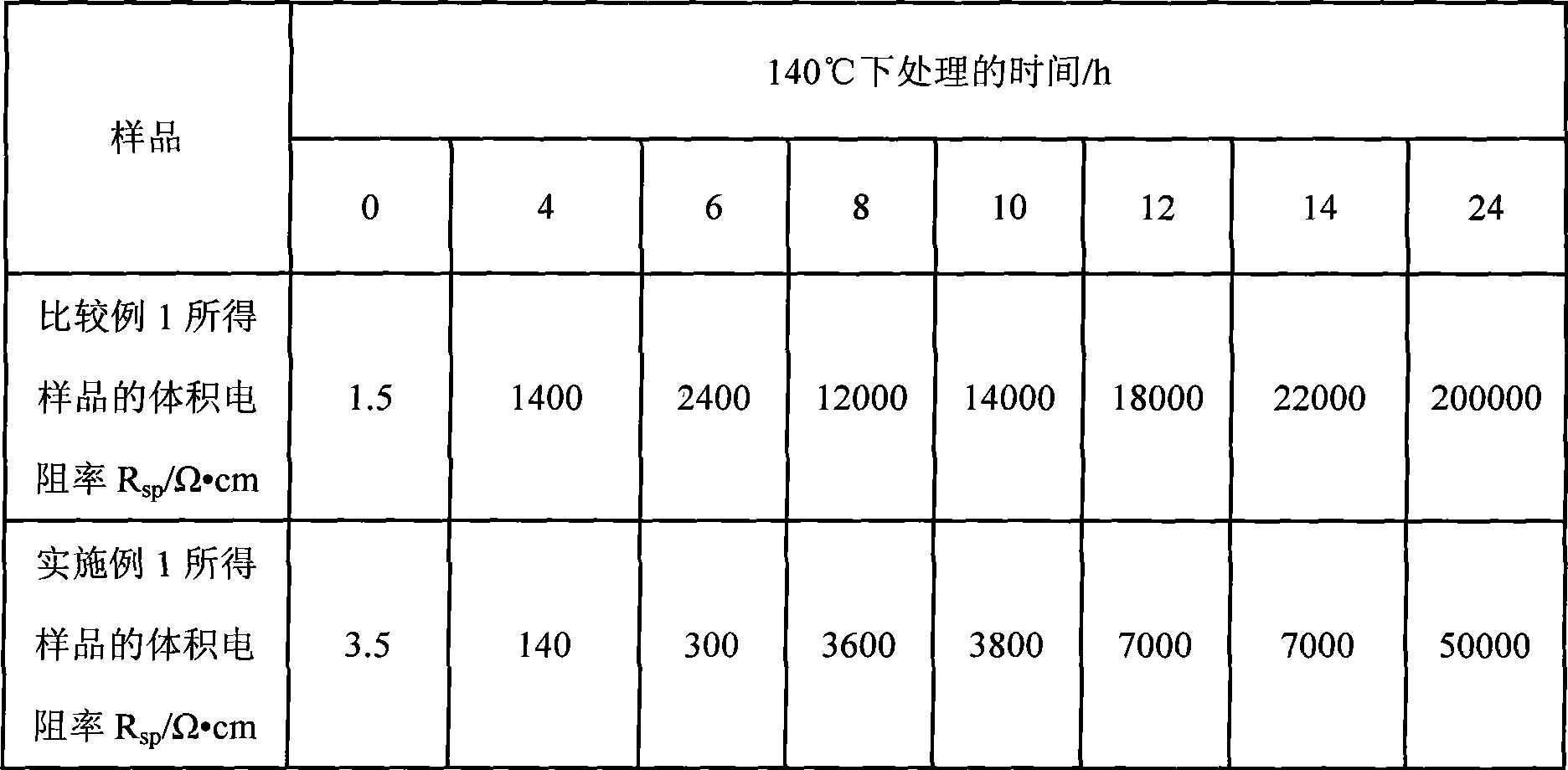

Embodiment 1

[0025] Embodiment 1: the aqueous dispersion liquid that 8g attapulgite and 90g deionized water are made, the mixed acid solution that the HCl of 3g (0.0118mol) sulfosalicylic acid and 25mL4.0M (0.1mol) forms and 2.4g (0.0258mol) aniline was added into a three-necked flask, and stirred evenly; 5.88g (0.0258mol) of ammonium persulfate was dissolved in 30mL of deionized water and then added to the slurry to initiate polymerization; stirred at 20°C for oxidative polymerization for 4h; suction filtered to obtain Hydrochloric acid and sulfosalicylic acid co-doped polyaniline / attapulgite nanocomposite filter cake.

[0026]Hydrochloric acid and sulfosalicylic acid co-doped polyaniline / attapulgite nanocomposite filter cake and xylene were added to a three-necked flask and mixed, and the three-necked flask was placed in an electric heating mantle, vigorously stirred and continuously heated. When boiling, a large amount of mixed steam will be generated, and the mixed steam will be conden...

Embodiment 2

[0027] Embodiment 2: In embodiment 2, remove filter cake to be sulfosalicylic acid doped polyaniline / silicon oxide nano-conductive composite material filter cake, be the aqueous dispersion liquid that is made by 8g silicon oxide and 8g deionized water , 2.4g (0.0258mol) aniline, 5g (0.0197mol) sulfosalicylic acid and 5.88g (0.0258mol) ammonium persulfate were in-situ polymerized at 0°C for 6h, the organic solvent was toluene, and the heat treatment time was 6h. Other operations are all the same as in Example 1 to obtain the sulfosalicylic acid-doped polyaniline / silicon oxide nano-conductive composite material powder treated with toluene, and its volume resistivity is measured to be 65 Ω cm, and the powder is placed in After being treated at 140°C for 4 hours, the volume resistivity becomes 300Ω·cm.

Embodiment 3

[0028] Embodiment 3: in embodiment 3, except that filter cake is dodecylbenzenesulfonic acid doped polyaniline / titanium oxide nano conductive composite material filter cake, is the water that is made of 8g titanium oxide and 260g deionized water Dispersion liquid, 6.4g (0.0688mol) aniline, 9.60g (0.0294mol) dodecylbenzenesulfonic acid and 15.68g (0.0688mol) ammonium persulfate were in-situ polymerized at 25°C for 4 hours, and the organic solvent was xylene. Except that the heat treatment time is 5h, other operations are all the same as in Example 1, and the dodecylbenzenesulfonic acid-doped polyaniline / titanium oxide nano-conductive composite material powder obtained through the xylene treatment, and its volume resistivity is measured to be 5Ω ·cm, the powder was treated at 140°C for 4h, and the volume resistivity became 20Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com