Preparation method of C-coated Mo<x>Co<1-x>S<2> composite positive electrode material

A moxco1-xs2, composite cathode material technology, applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve problems such as the inability to meet the use requirements of lightweight thermal batteries and the inability to exert complementary advantages, and achieve electrical conductivity. Excellent performance, better thermal stability and higher specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

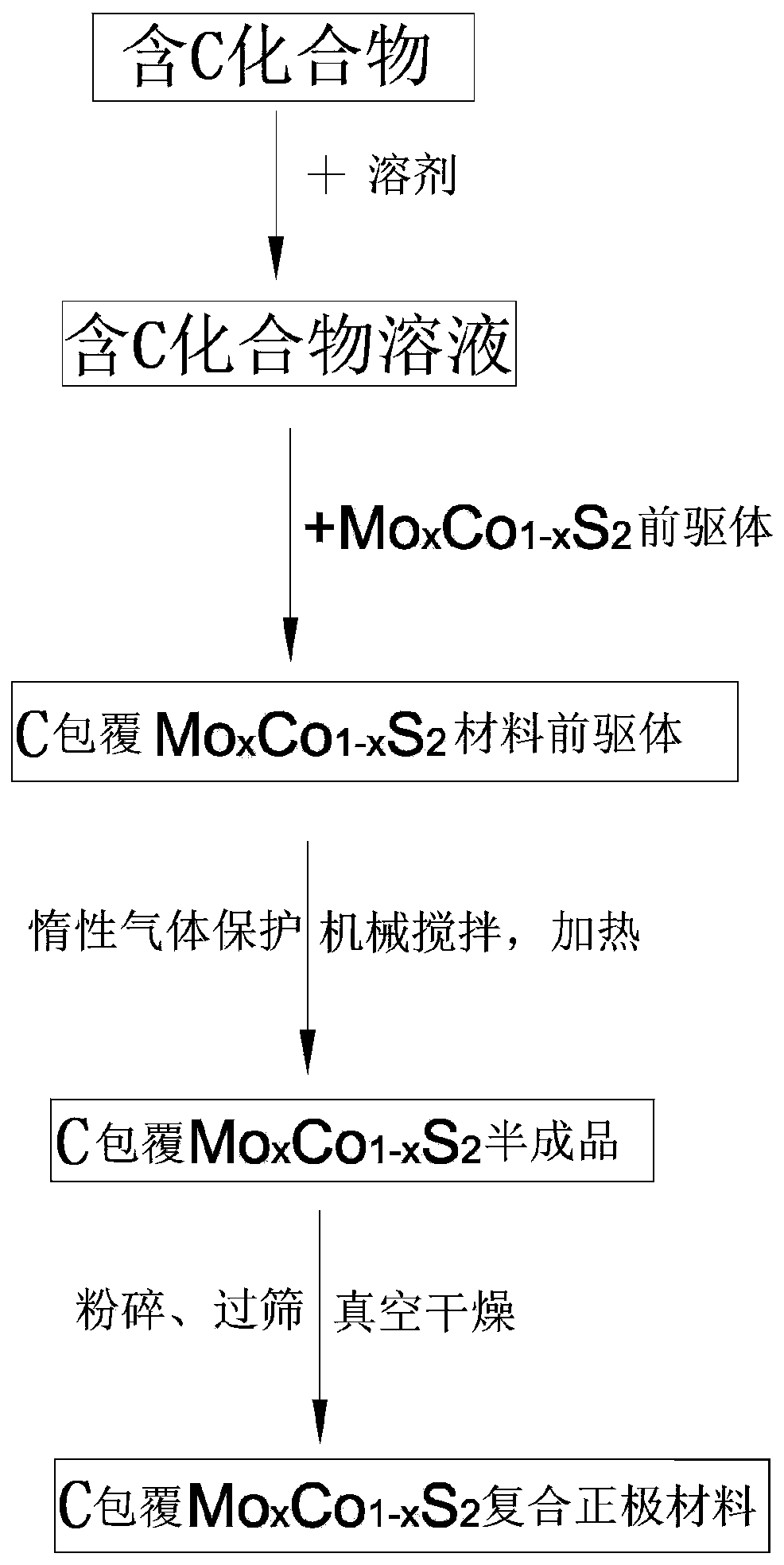

[0035] Such as figure 1 , A C coated Mo x Co 1-x S 2 The preparation method of the composite cathode material includes the following steps:

[0036] Step 1: Weigh the C-containing compound and dissolve it in a solvent of 20 times its mass to form a C-containing compound solution; the C-containing compound is a C-containing organic matter, the C-containing organic matter is glucose, and the C-containing compound is C content is 15%;

[0037] Step 2: Dissolve the Mo source in a solvent of 30 times its volume, then add the Co source, stir evenly for 2 hours, and then add the sulfur source and stir for full reaction to obtain Mo x Co 1-x S 2 Precursor; the Mo source is Na 2 MoO 4 , (NH 4 ) 2 MoO 4 , And the Mo content in the Mo source is 32%; the Co source is CoCl 2 , And the Co content in the Co source is 20%; the sulfur source is NaS 2 , Its S content is 70%; the mass ratio of the Mo source, Co source and sulfur source = 8:5:12;

[0038] Step 3: Put the above Mo x Co 1-x S 2 The precur...

Embodiment 2

[0043] Such as figure 1 , A C coated Mo x Co 1-x S 2 The preparation method of the composite cathode material includes the following steps:

[0044] Step 1: Weigh the C-containing compound and dissolve it in a solvent of twice its mass to form a C-containing compound solution; the C-containing compound is a C-containing organic matter, the C-containing organic matter is ethyl acetate, and the C-containing compound is The content of C in the compound is 90%;

[0045] Step 2: Dissolve Mo source in a solvent twice its volume, then add Co source, stir evenly for 1.5~2.3h, then add sulfur source and stir for full reaction to obtain Mo x Co 1-x S 2 Forebody; the Mo source is K 2 MoO 4 , And the Mo source contains 28% of the total material; the Co source is CoCl 2 , And the Co source contains 18% of the total material; the sulfur source is thiourea, and its S content is 40%; the mass ratio of the Mo source, the Co source and the sulfur source is = 4:1: 10;

[0046] Step 3: Put the above Mo...

Embodiment 3

[0051] Such as figure 1 , A C coated Mo x Co 1-x S 2 The preparation method of the composite cathode material includes the following steps:

[0052] Step 1: Weigh the C-containing compound and dissolve it in a solvent 300 times its mass to form a C-containing compound solution; the C-containing compound is a C-containing organic matter, the C-containing organic matter is cellulose, citric acid, and the The C content in C-containing compounds is 20%;

[0053] Step 2: Dissolve the Mo source in a solvent 300 times its volume, then add the Co source, stir evenly for 2.3 hours, and then add the sulfur source and stir for full reaction to obtain Mo x Co 1-x S 2 Precursor; the Mo source is Na 2 MoO 4 , And the Mo content in the Mo source is 56%; the Co source is CoCl 2 , Na 2 CoO 2 , And the Co content in the Co source is 42%; the sulfur source is sulfur powder, and the S content is 90%; the mass ratio of the Mo source, the Co source and the sulfur source is = 14:21:25;

[0054] Step 3: Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com