Transparent heating membrane and its mfg. method

A manufacturing method and technology of heating film, applied in the direction of heating element materials, etc., can solve problems such as not being suitable for popularization and application, not resistant to dry burning, short life, etc., and achieve improved conductivity and thermal stability, not easy to break, and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

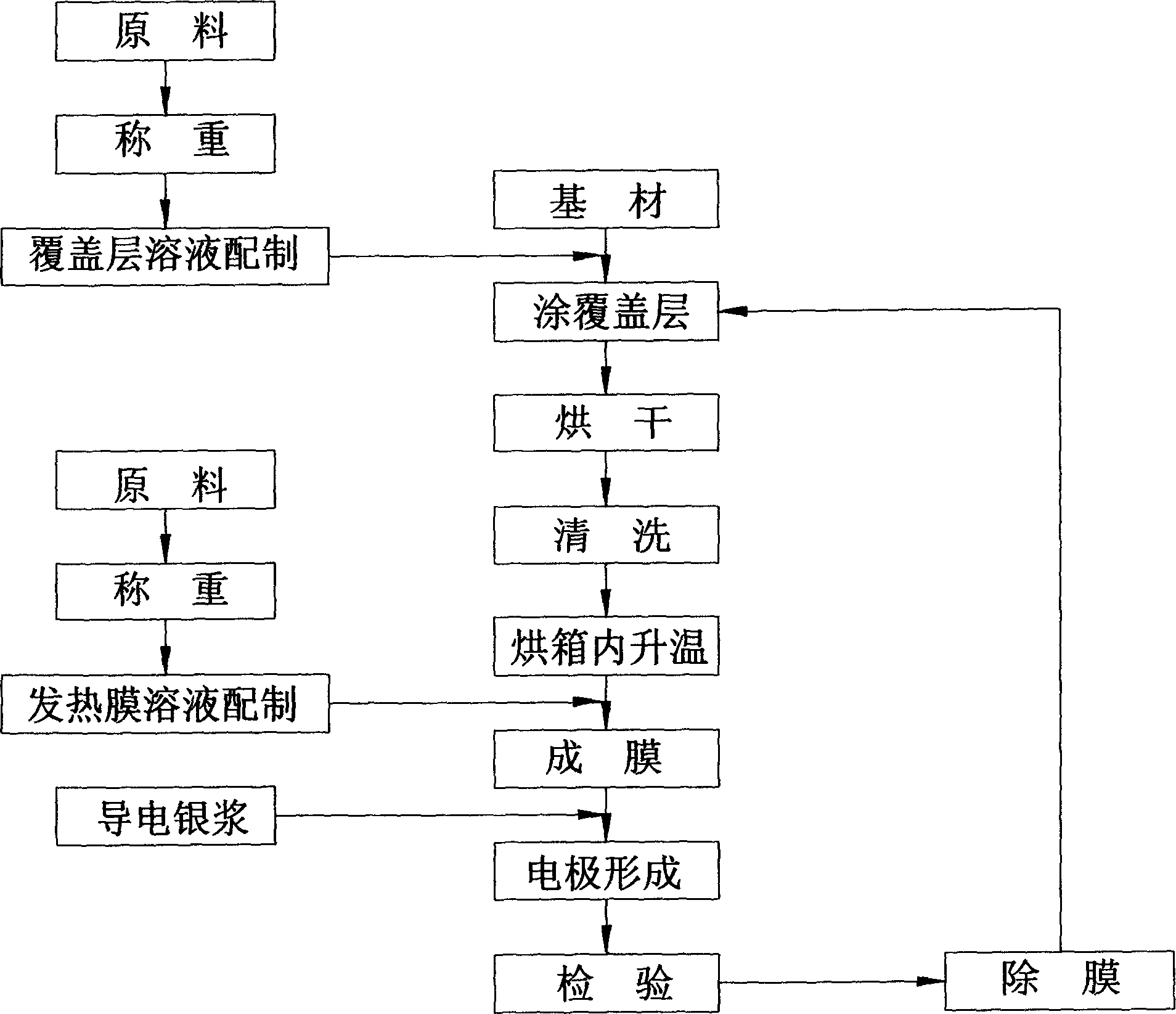

Image

Examples

Embodiment

[0027] Embodiment: a kind of transparent heating film, adopts following formula:

[0028] InCl 3 : 5.2 grams;

[0029] SnCl 4 5.2 grams;

[0030] BiCl 3 : 5.2 grams;

[0031] HCl: 100 ml;

[0032] Methanol: 450 ml;

[0033] Water: 460ml.

[0034] The following manufacturing methods are used:

[0035] (1) Take InCl 3 52 g, SnCl 4 ·5H 2 O 5.2 g, BiCl 3 5.2 grams, 450ml of methanol, pour the above four substances into container A, mix and stir evenly, take 100ml of HCl, and pour 460ml of water into container B, mix and stir evenly, then slowly pour the solution in container B into the container In A, stir slowly and evenly at the same time, and use it as a substrate for spraying film;

[0036] (2) Production of the cover layer: the function of the cover layer is to block the part that does not need to be sprayed with the heating film, take 200g of large stone powder, 20ml of M1 water-soluble glue, H 2 O 200ml Put these three substances in a container, mix and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com