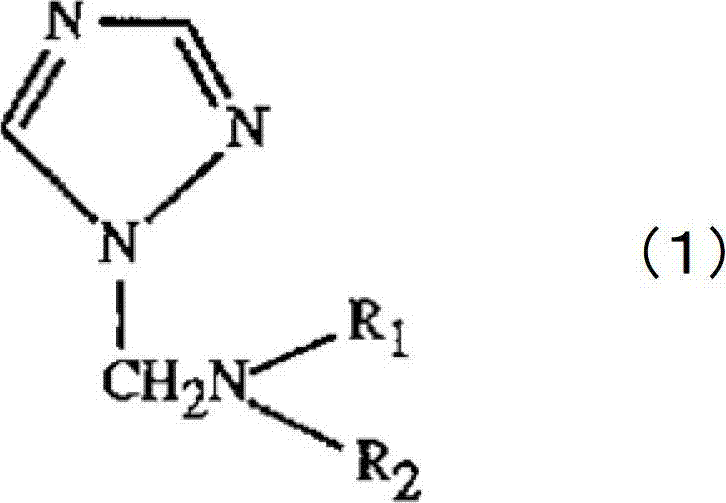

Resin composition for ultraviolet curable adhesive and adhesive

A resin composition and adhesive technology, applied in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of undiscovered materials, and achieve excellent polymerizability, excellent water resistance, and excellent holding power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

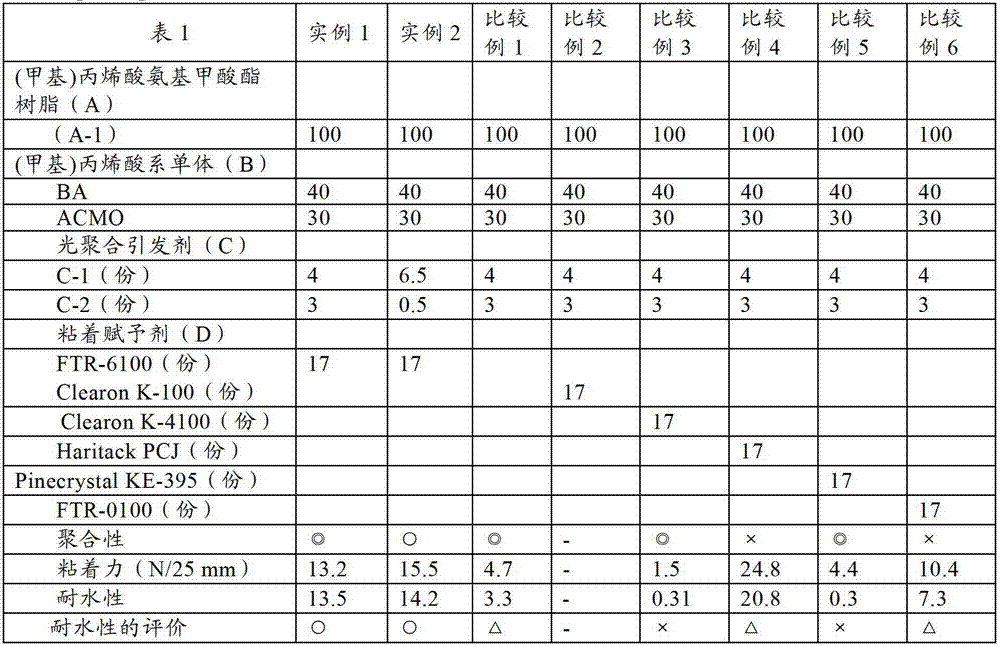

[0108] Hereinafter, the present invention will be described in more detail using examples.

Synthetic example 1

[0110] Synthesis of (meth)acrylic urethane resin (A-1)

[0111] To a reaction vessel equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, and a thermometer, 465.9 parts by mass of polytetramethylene glycol (hydroxyl value 112 mgKOH / g), 9.6 parts by mass of 2-hydroxyethyl acrylate, 2,6 - 1.7 parts by mass of di-tert-butyl-cresol, 0.3 parts by mass of p-methoxyphenol. After the temperature in the reaction container was heated up to 40°C, 101.5 parts by mass of isophorone diisocyanate was added. Furthermore, 0.06 mass parts of dioctyltin dineodecanoates were added, and it heated up to 80 degreeC over 1 hour. Then, after holding|maintaining at 80 degreeC for 12 hours and confirming that all the isocyanate groups disappeared, it cooled and obtained (meth)acryl urethane resin (A-1). The obtained (meth)acrylic urethane resin (A-1) had an equivalent weight of an acryloyl group of 7,000, and a weight average molecular weight of 18,000.

example 1

[0113] To a container equipped with a stirrer, a reflux cooling pipe, and a thermometer, 100 parts by mass of the (meth)acrylic urethane resin (A-1) obtained in Synthesis Example 1 and 40 butyl acrylate were added at a temperature of 80° C. in the container. Parts by mass, 30 parts by mass of acryloylmorpholine, 17 parts of FTR-6100 (manufactured by Mitsui Chemicals Co., Ltd., weight average molecular weight: 1,154, number average molecular weight: 612, melt viscosity at 200° C.: 60 mPa·s), stirred to until uniform. Then, after cooling to room temperature, 4 parts by mass of 2-hydroxy-2-methyl-1-phenylpropane-1-one, 2,4,6-trimethoxybenzoyldiphenylphosphine oxide were added successively under stirring. 3 parts by mass, stir until uniform. Then, it filtered through the 200-mesh wire mesh, and obtained the resin composition for ultraviolet curing adhesives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com