Separation system and separation method for piperylene and dicyclopentadiene

A technology of dicyclopentadiene and piperylene, which is applied in distillation purification/separation, hydrocarbon production by addition of unsaturated hydrocarbons, organic chemistry, etc., can solve the problem that high-purity piperylene and dicyclopentadiene cannot be obtained. and other problems, to achieve the effect of small reflux, reducing load and saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

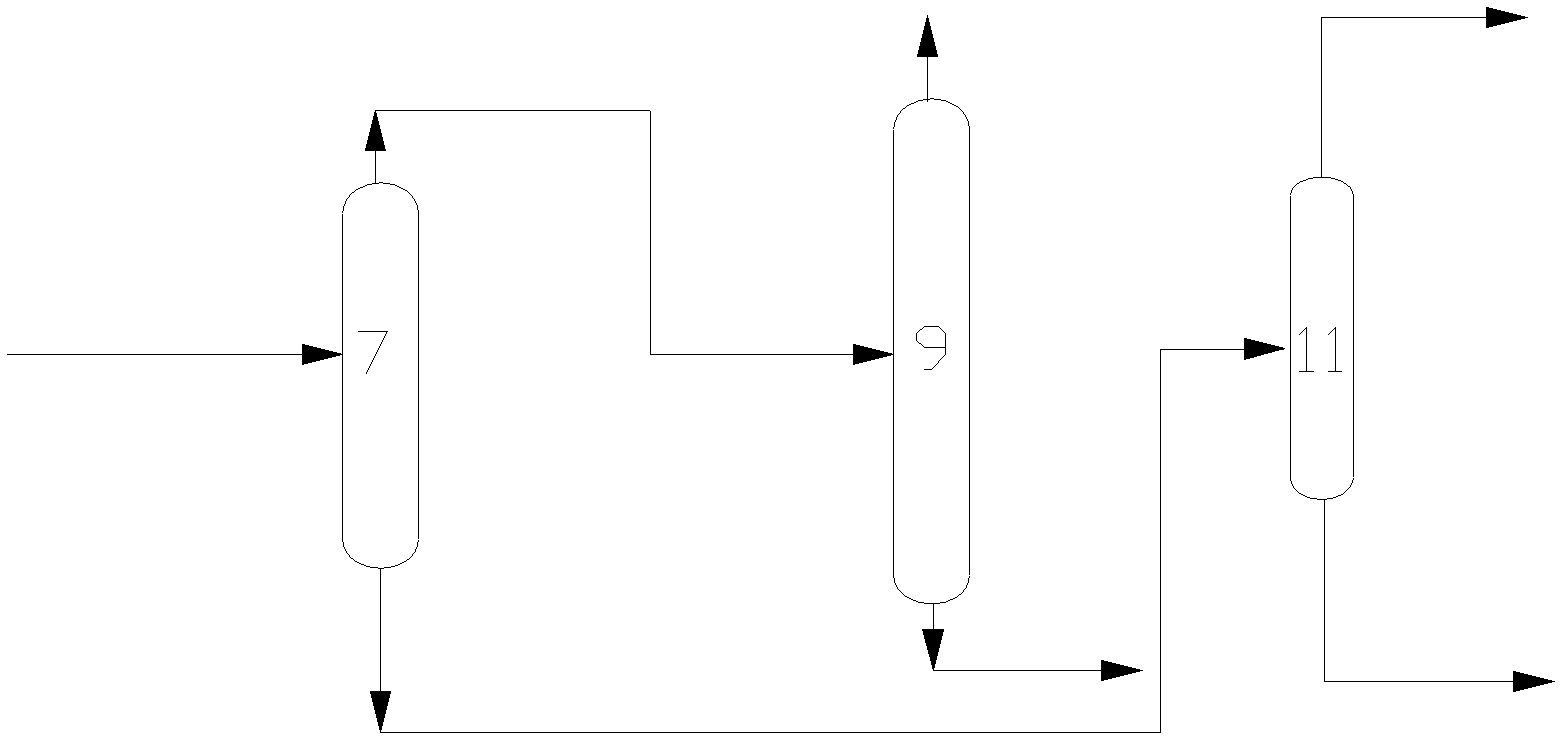

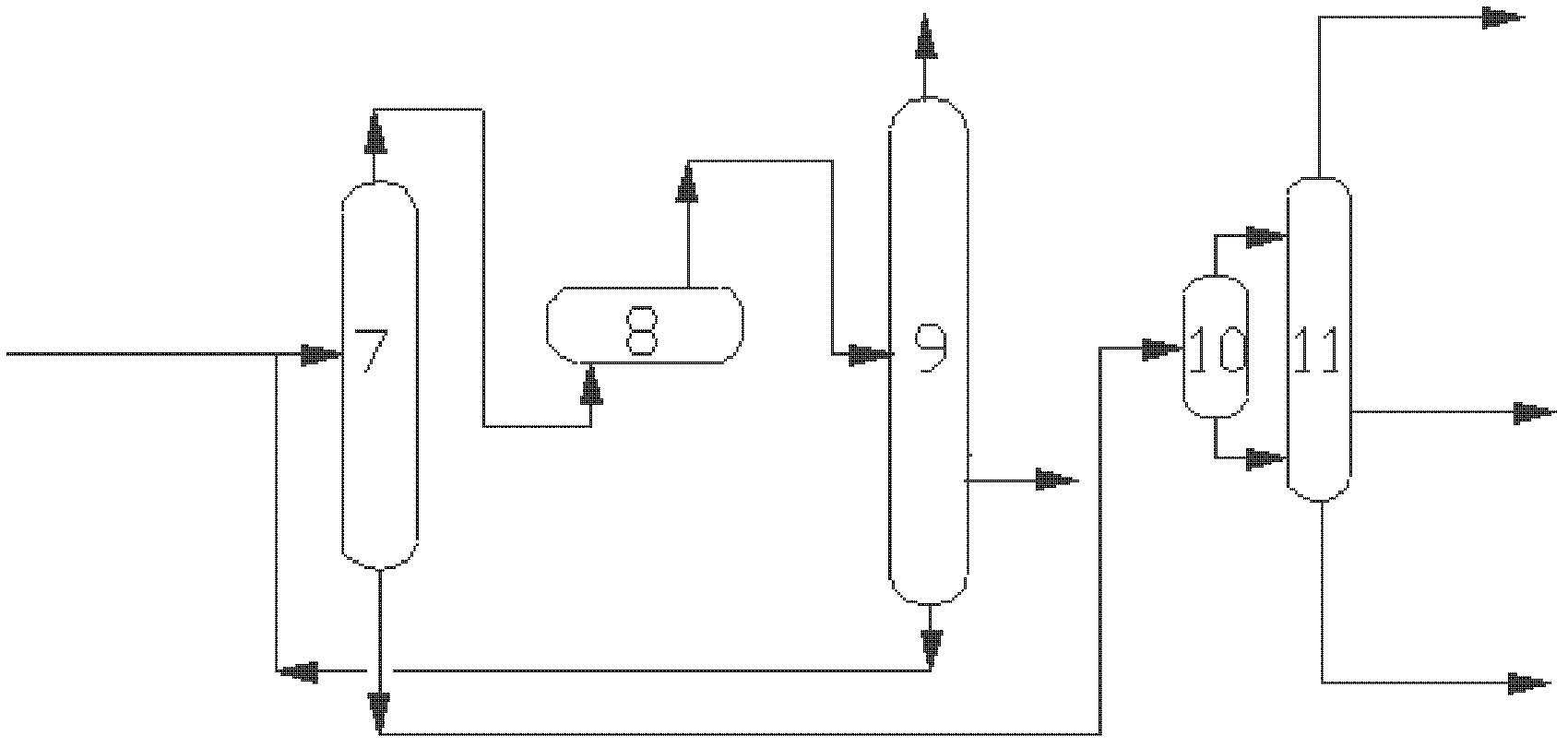

[0035] like figure 2 Shown, a separation system of piperylene and dicyclopentadiene.

[0036] Including: carbon five distillation tower 7, piperylene tower 9 and dicyclopentadiene tower 11,

[0037] A second dimerization reactor 8 is arranged between the carbon five steaming tower 7 and the piperylene tower 9; a double-ring feed flash tank 10 is arranged before the dicyclopentadiene tower 11;

[0038] The top of the carbon five steaming tower 7 is connected to the second dimerization reactor 8 and then connected to the middle part of the piperylene tower 9; the bottom of the carbon five steaming tower 7 is connected to the double ring feed flash tank 10, and the double ring feed flash tank 10 The top and bottom are respectively connected to the upper and lower parts of the dicyclopentadiene tower 11;

[0039] When separating,

[0040] (1) The carbon five cuts that come from the bottom of the pre-weight removal tower and the weight removal tower enter the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com