Patents

Literature

44results about How to "Suitable for industrial scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

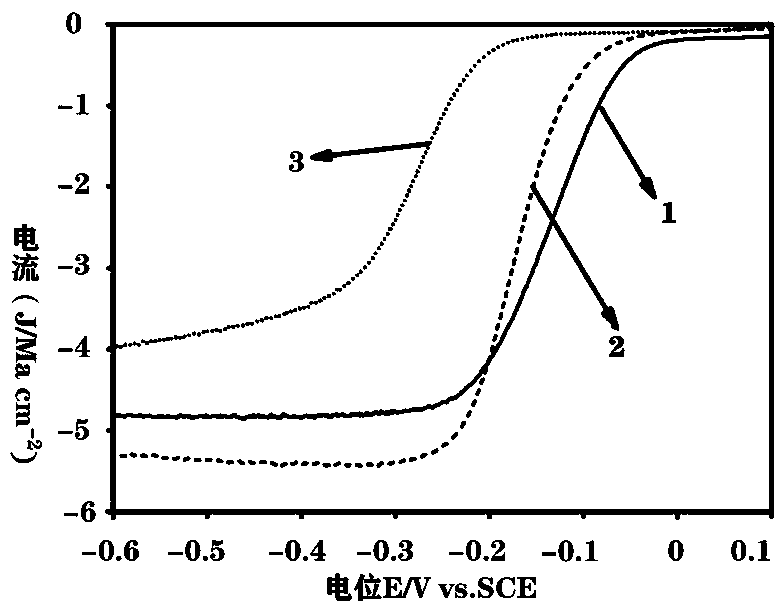

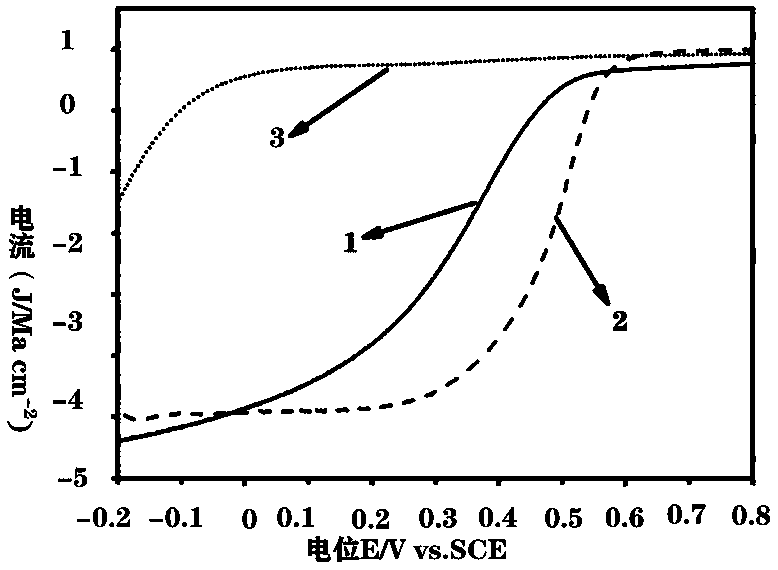

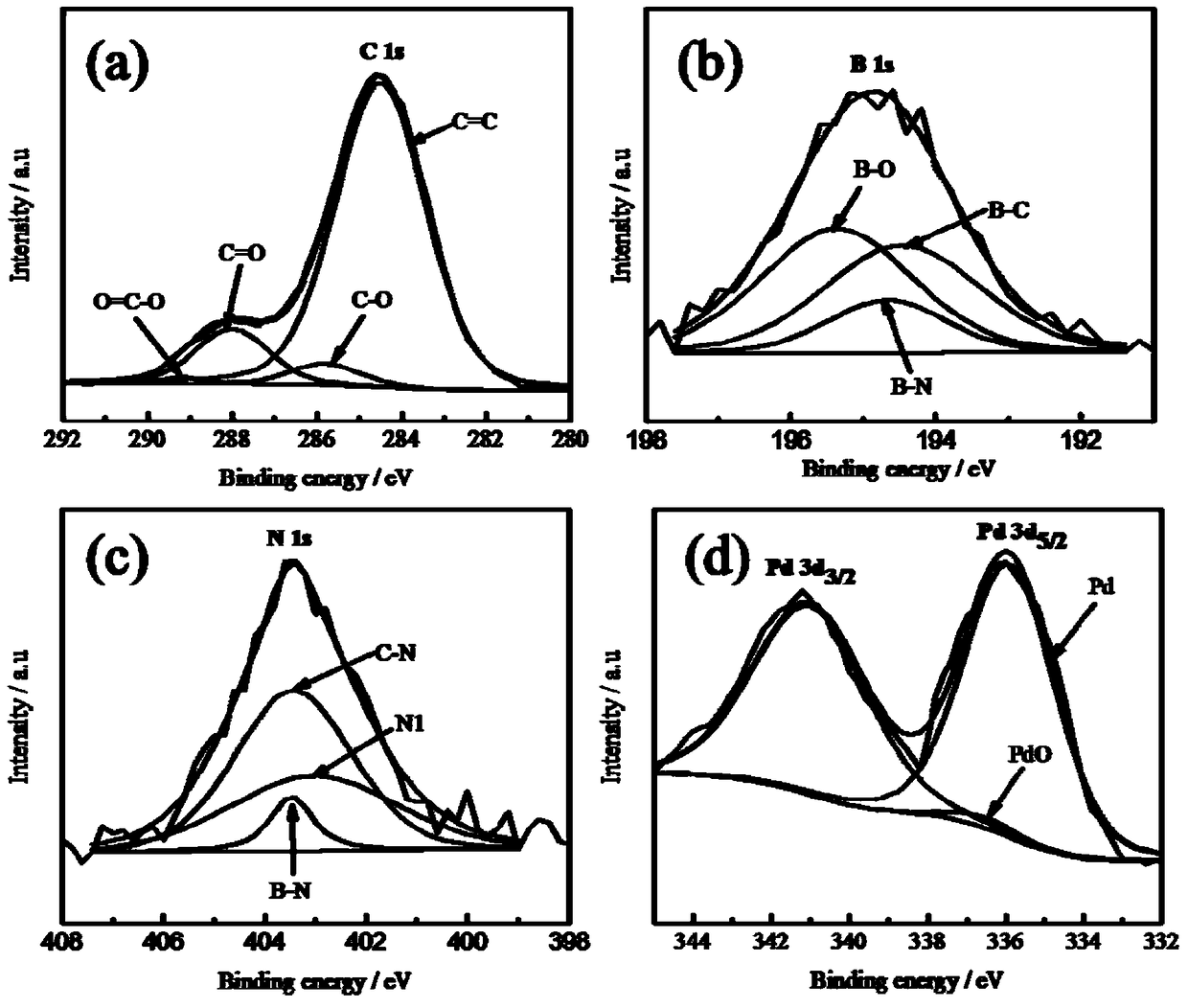

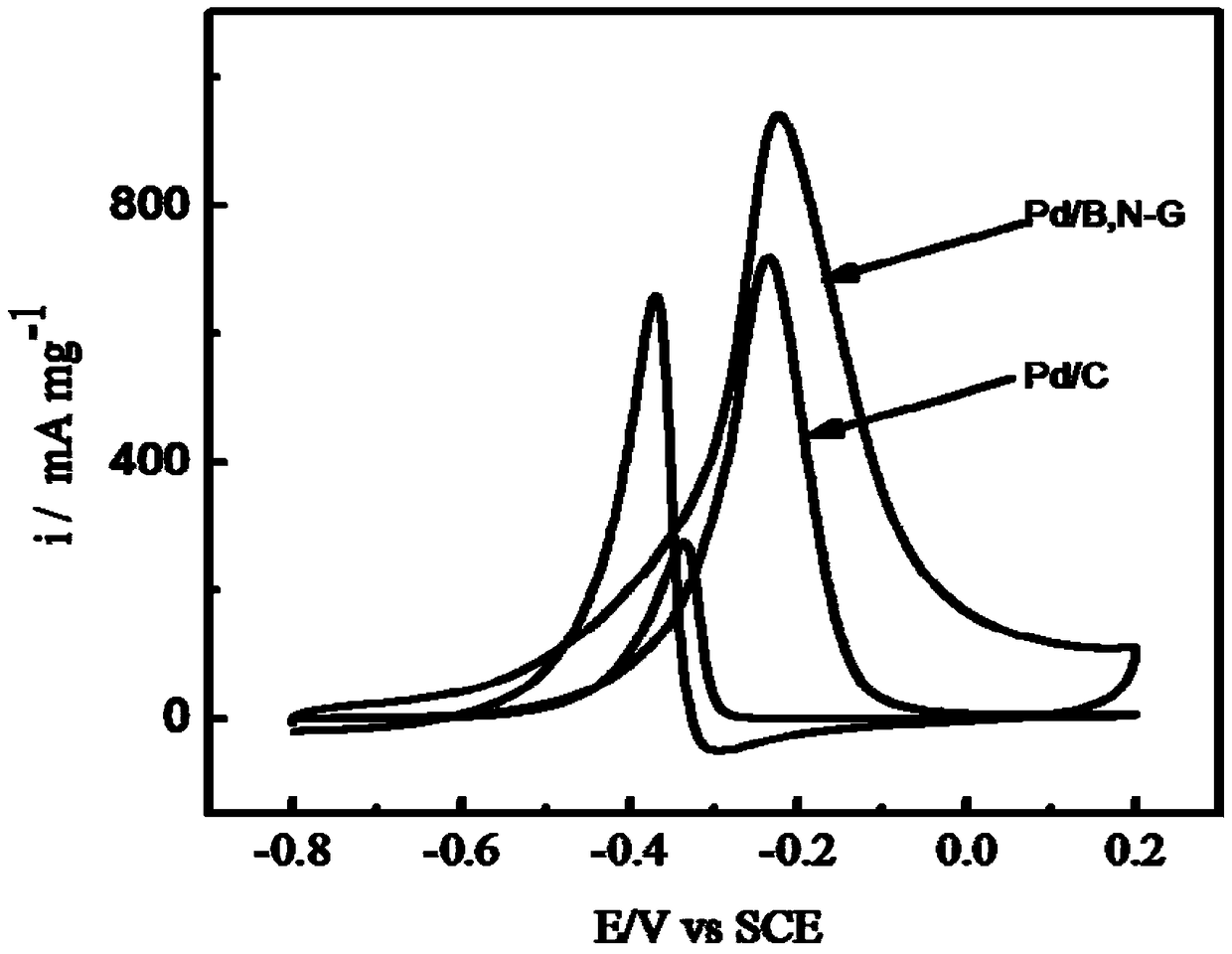

Preparation method of heteroatom doped graphene-based material supported noble metal nanoparticles

ActiveCN105591115ASimple preparation processHigh economic valueMaterial nanotechnologyCell electrodesPrecious metalNoble metal

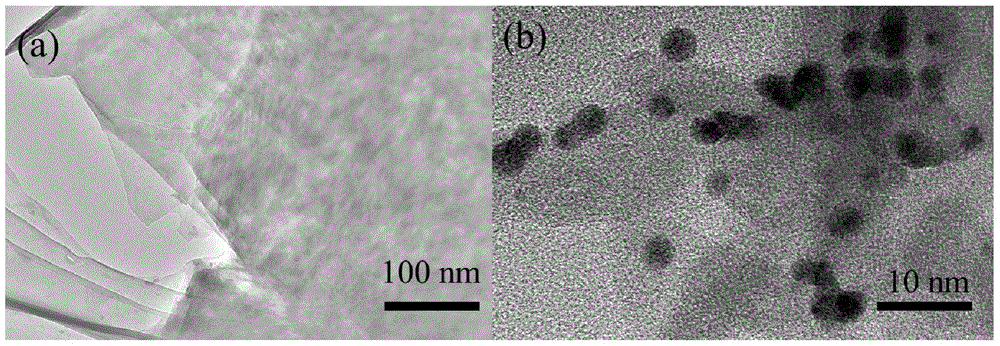

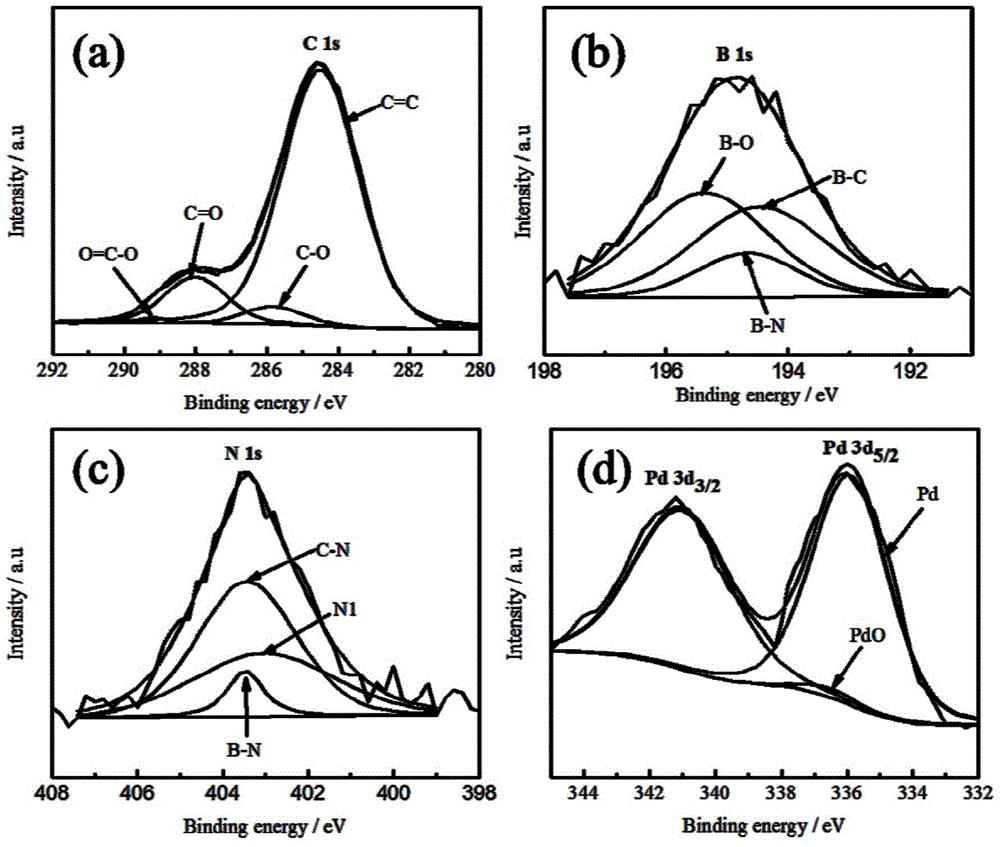

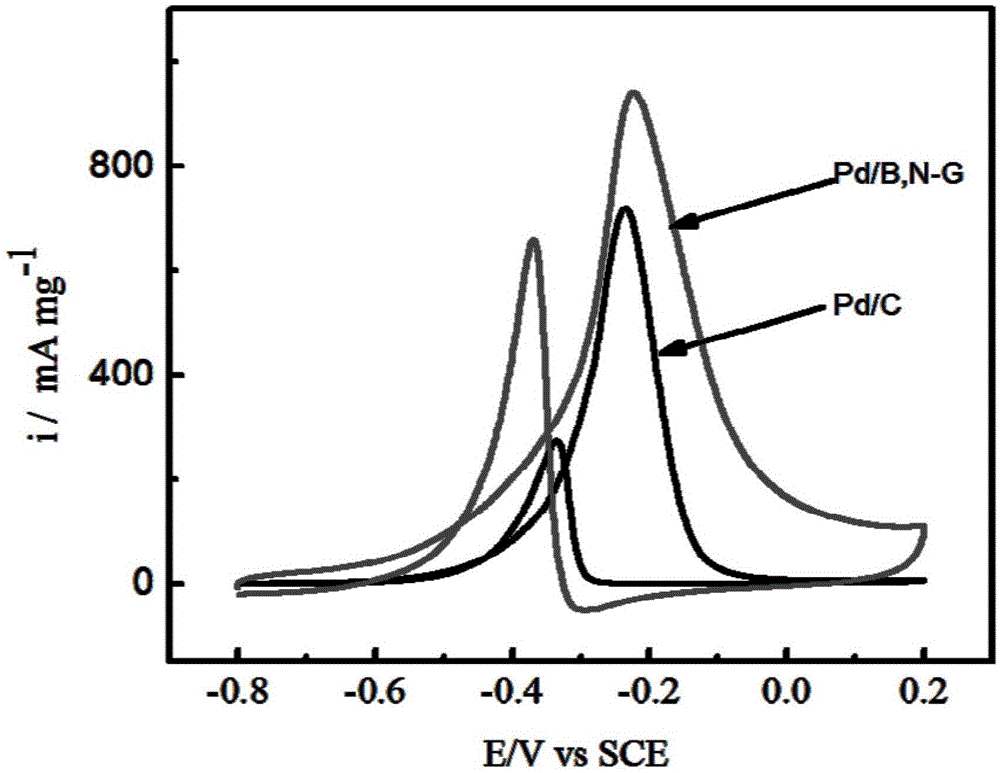

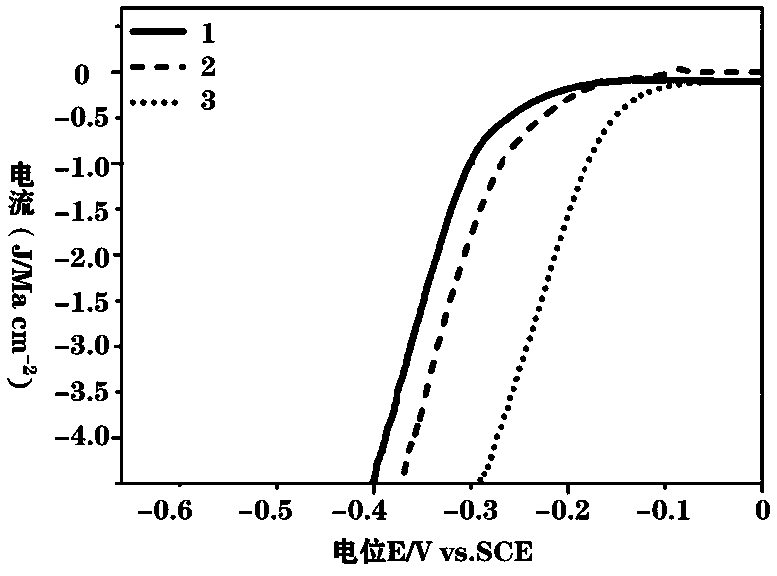

The invention provides a preparation method of heteroatom doped graphene-based material supported noble metal nanoparticles. The preparation method comprises steps as follows: preparation of a heteroatom doped graphene-based material: a graphene-based material is subjected to ultrasonic treatment, a heteroatom precursor is added, heteroatom doping is performed in a hydrothermal kettle at the temperature of 150-200 DEG C, and the heteroatom doped graphene-based material is obtained; preparation of the heteroatom doped graphene-based material supported noble metal nanoparticles: the heteroatom doped graphene-based material is dissolved in deionized water and subjected to ultrasonic treatment, a stabilizer and a metal precursor are added, metal in the metal precursor is platinum, palladium, gold or silver, the mixture is continuously stirred, pH is adjusted to range from 8 to 14, a reduction agent is added, the mixture is continuously stirred, and the heteroatom doped graphene-based material supported noble metal nanoparticles are obtained after vacuum drying. The synergistic effect of the heteroatom and the carrier on noble metal is used, the activity and the stability of a catalyst are effectively improved, and a preparation process is simple and suitable for industrial production and has higher economic value.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

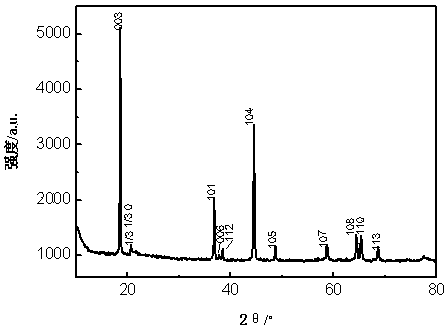

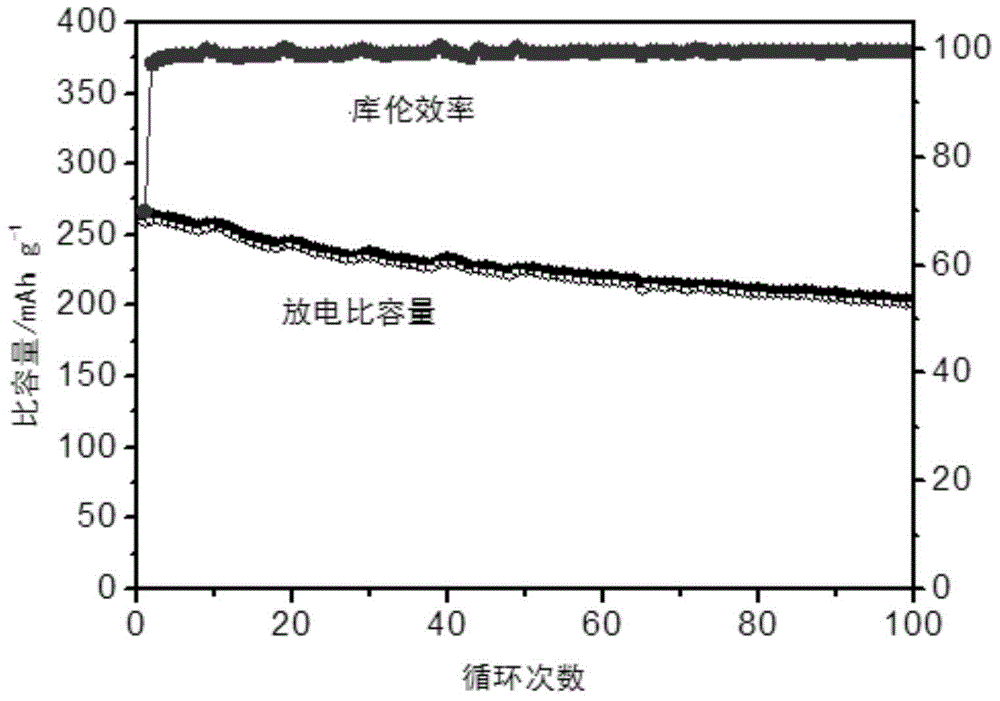

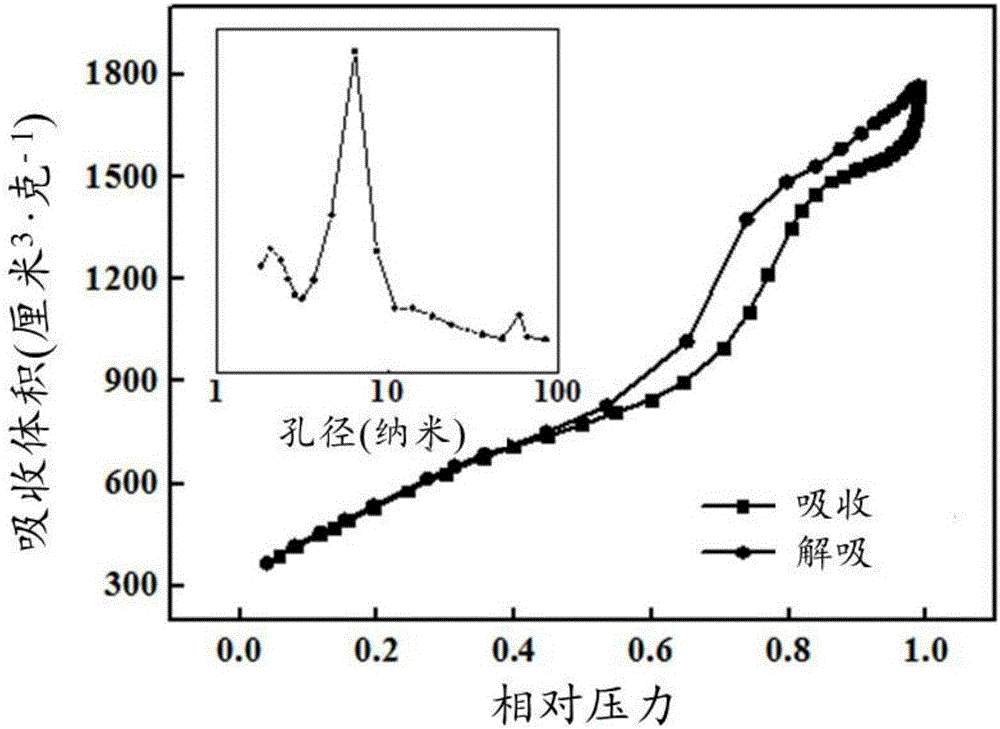

Preparation method of cathode material of lithium-rich ternary compound lithium ion battery

InactiveCN103956477AUniform precipitationSimple processCell electrodesSecondary cellsWater bathsNickel salt

The invention discloses a preparation method of a cathode material of a lithium-rich ternary compound lithium ion battery. The molecular formula of the cathode material is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the steps of firstly, stirring an organic precipitant in constant temperature water bath to dissolve the organic precipitant in an organic solvent to obtain a solution I; after that, ultrasonically dissolving soluble cobalt salt, nickel salt, manganese salt and lithium salt in deionized water to obtain a solution II; then, dropwise adding the solution II into the solution I at constant speed, and carrying out a reaction at the temperature of 40-80 DEG C for 2h-4h; drying at 100-120 DEG C; and heating the obtained solid powder in a high temperature tube furnace system by stages, calcining, and cooling the product to room temperature along with the furnace to obtain the lithium-rich ternary compound lithium ion battery cathode material which is good in electrochemical performance and uniform in particles, and has a spherical or ellipsoidal morphology feature. The preparation technology is simple and suitable for industrial scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

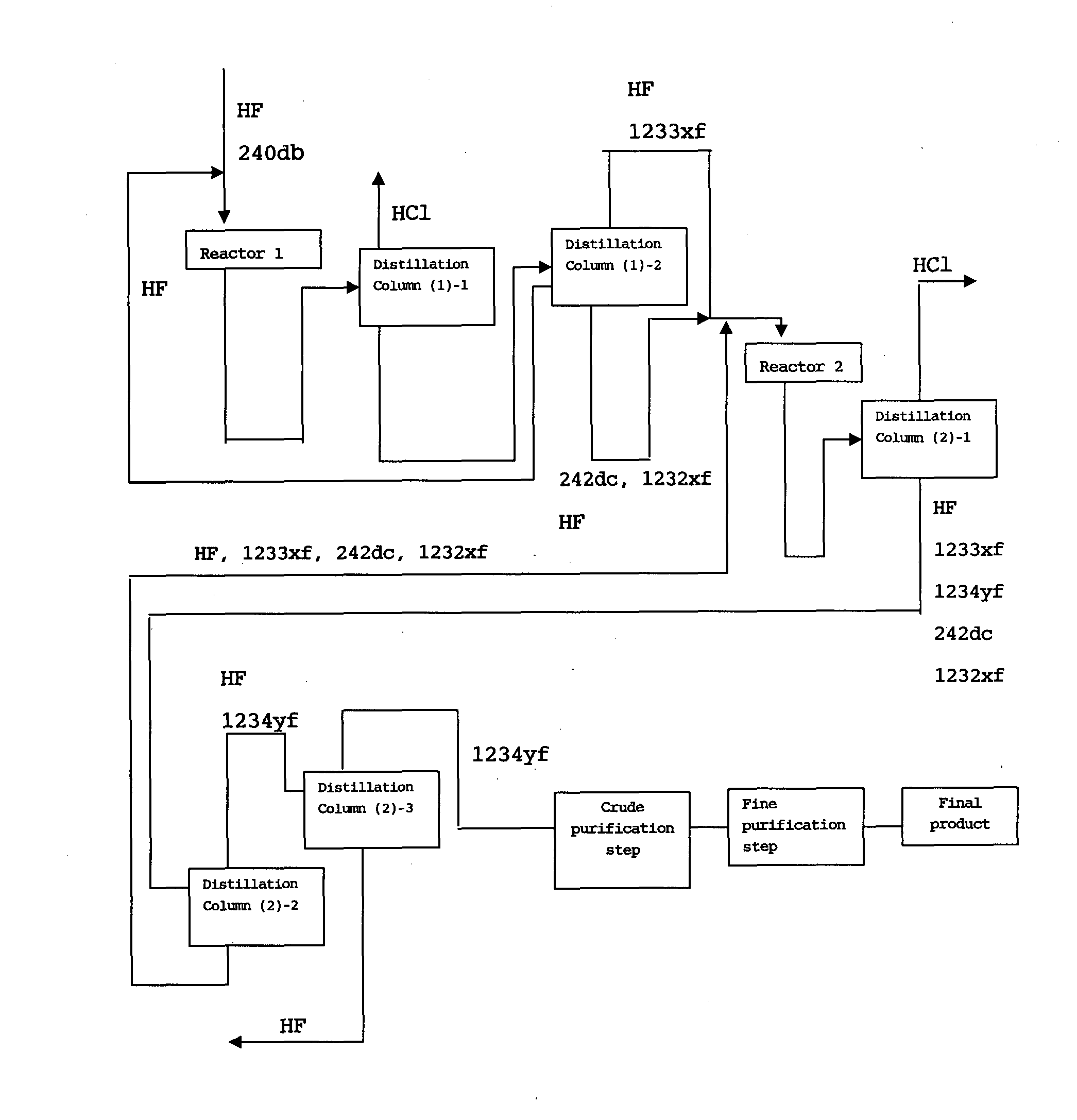

Process for producing 2,3,3,3-tetrafluoropropene

ActiveUS20130217928A1High selectivityCatalyst deterioration can be suppressedPreparation by hydrogen halide split-offMicrobiological testing/measurementHydrogen fluoridePolymer science

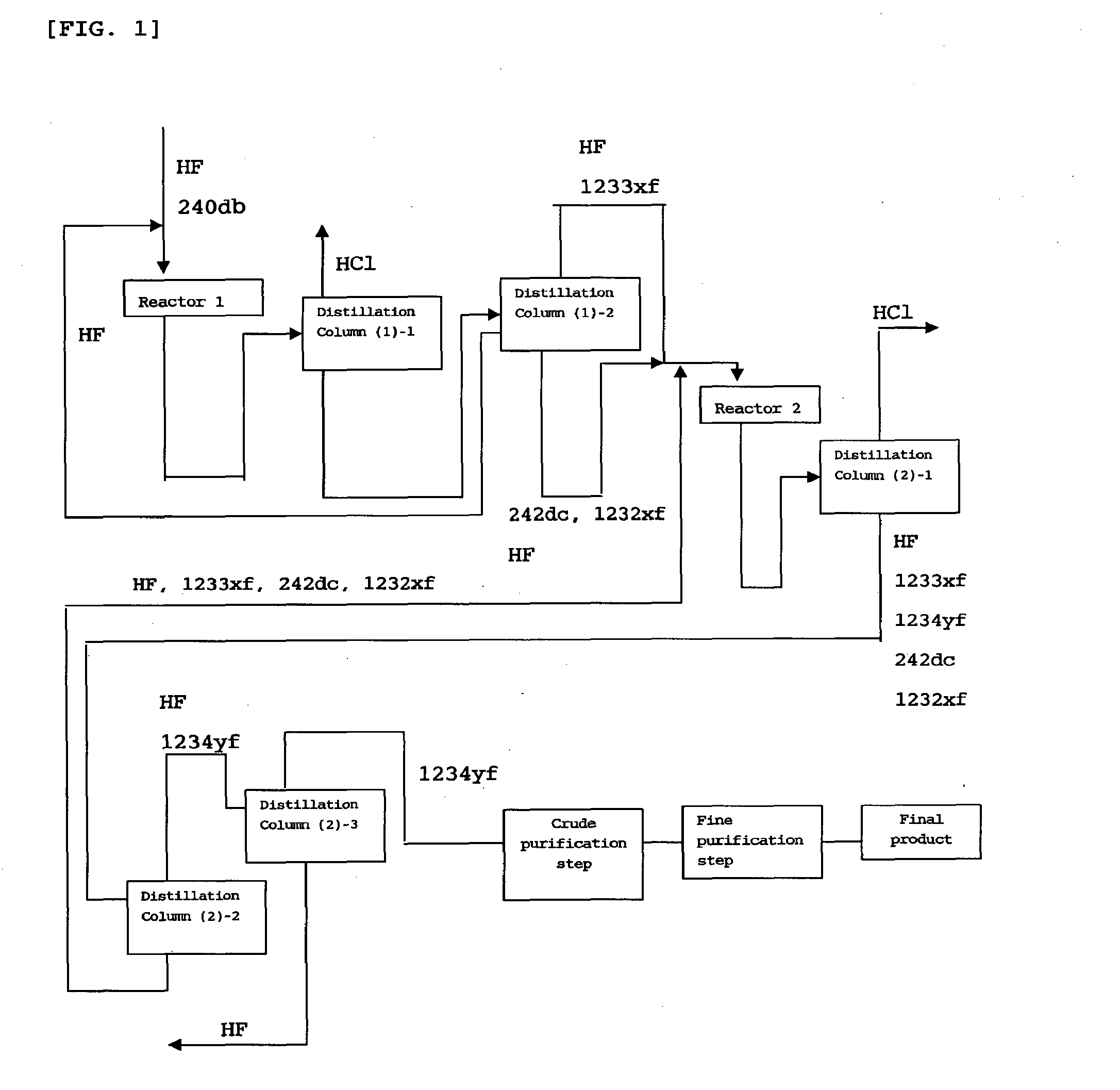

This invention provides a process for producing 2,3,3,3-tetrafluoropropene, the process comprising: (1) a first reaction step of reacting hydrogen fluoride with at least one chlorine-containing compound selected from the group consisting of a chloropropane represented by Formula (1): CClX2CHClCH2Cl, wherein each X is the same or different and is CI or F, a chloropropene represented by Formula (2): CClY2CCl═CH2, wherein each Y is the same or different and is CI or F, and a chloropropene represented by Formula (3): CZ2═CClCH2Cl, wherein each Z is the same or different and is CI or F in a gas phase in the absence of a catalyst while heating; and (2) a second reaction step of reacting hydrogen fluoride with a reaction product obtained in the first reaction step in a gas phase in the presence of a fluorination catalyst while heating. According to the process of this invention, 2,3,3,3-tetrafluoropropene (HFO-1234yf) can be obtained with high selectivity, and catalyst deterioration can be suppressed.

Owner:DAIKIN IND LTD

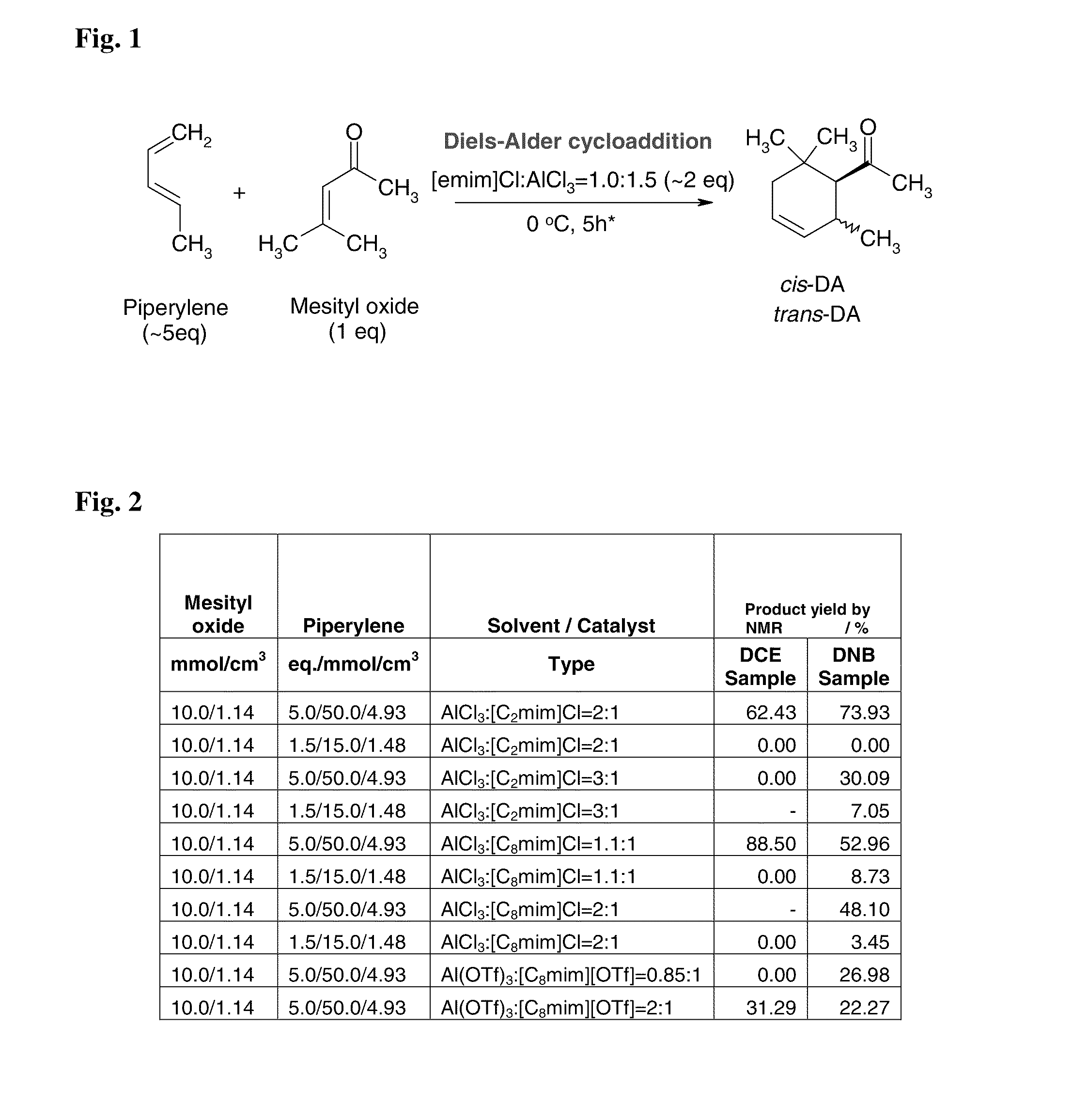

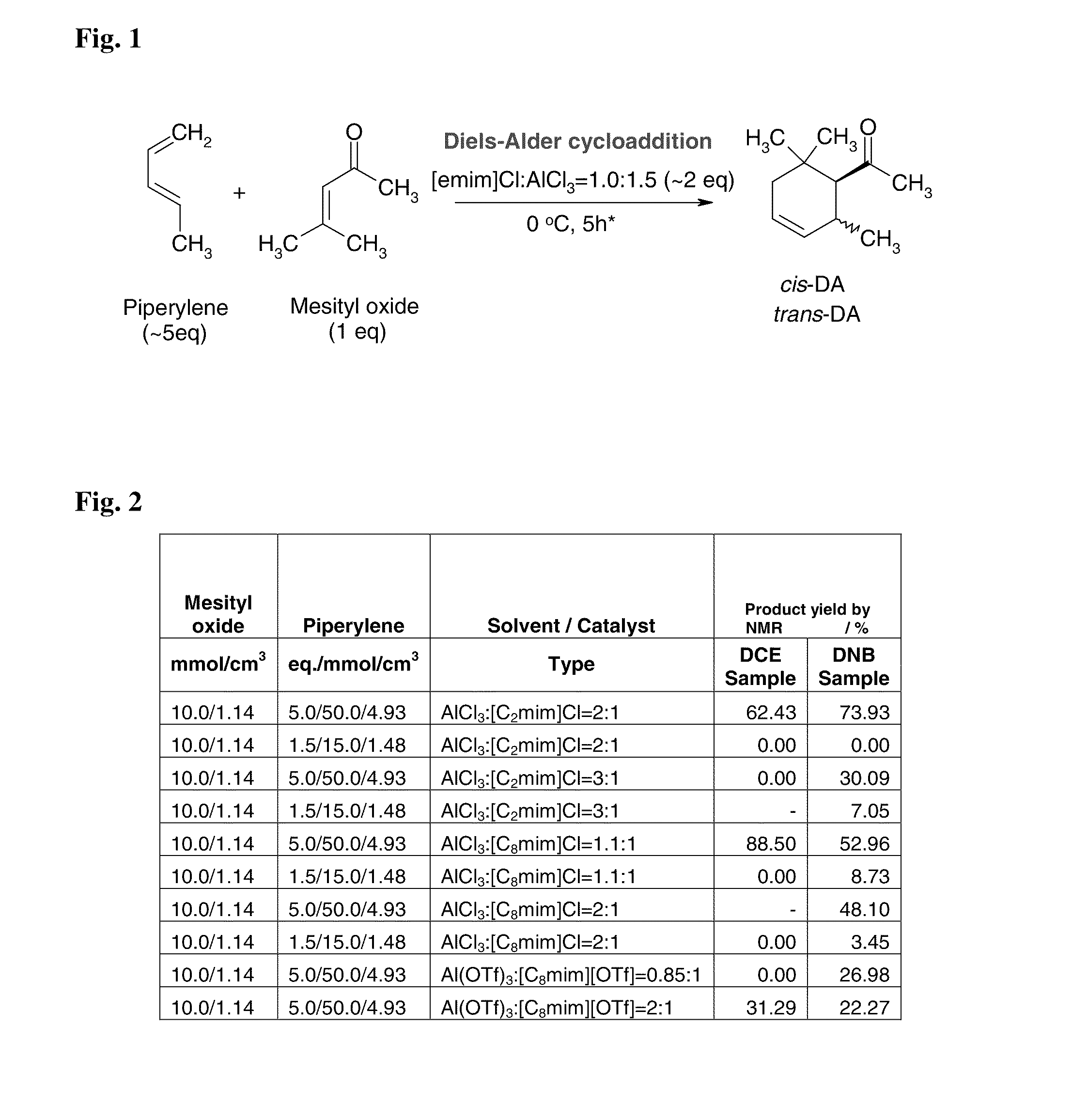

Process for Conducting an Organic Reaction in Ionic Liquids

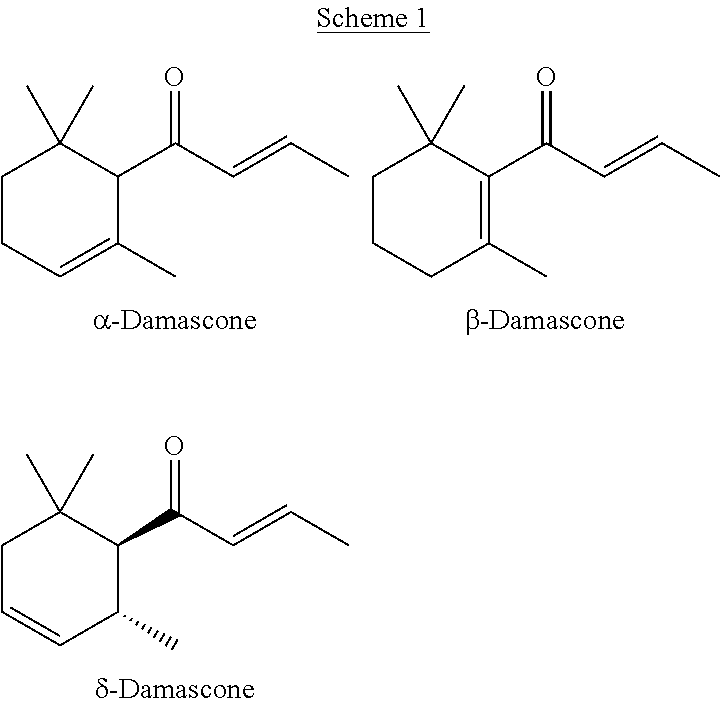

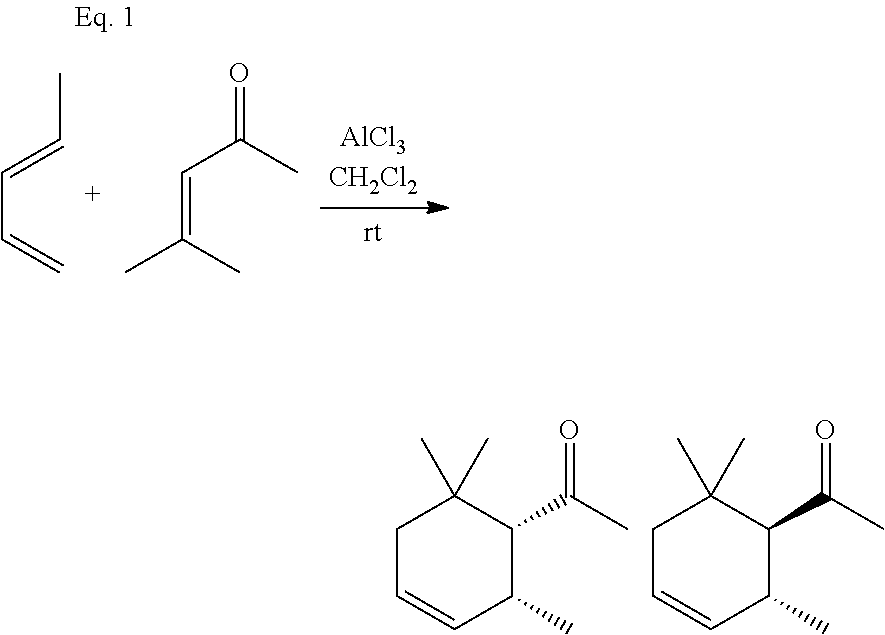

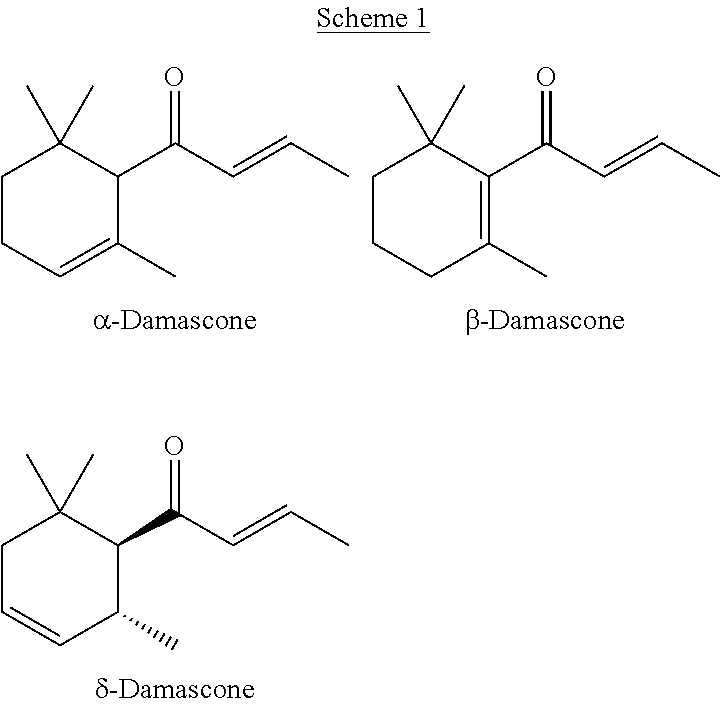

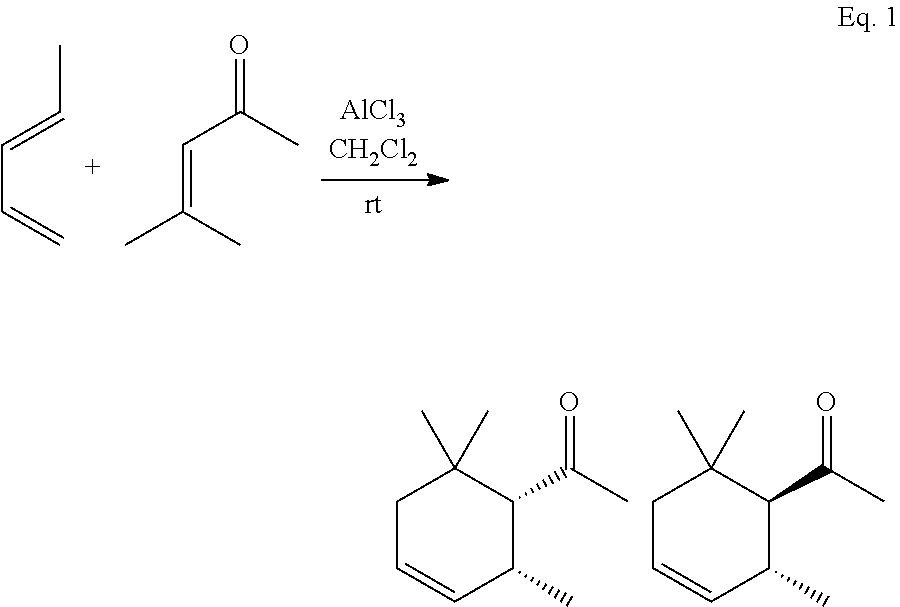

InactiveUS20110152566A1High yieldSuitable for industrial scaleOrganic compound preparationCarbonyl compound preparationPiperyleneIon

The present disclosure describes processes for producing cyclohexenes using Lewis acidic ionic liquids comprising the steps of providing to a reactor an α,β-unsaturated carbonyl dienophile, providing to the reactor a 1,3-diene, providing a Lewis acidic ionic liquid to the reactor; and reacting the α,β-unsaturated carbonyl dienophile with 1,3-diene to form a substituted cyclohexene product. The α,β-unsaturated carbonyl dienophile can be mesityl oxide, the 1,3-diene can be piperylene; and the Lewis acidic ionic liquid can be AlCl3:[C2mim]Cl; AlCl3:[C8mim]Cl; or mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

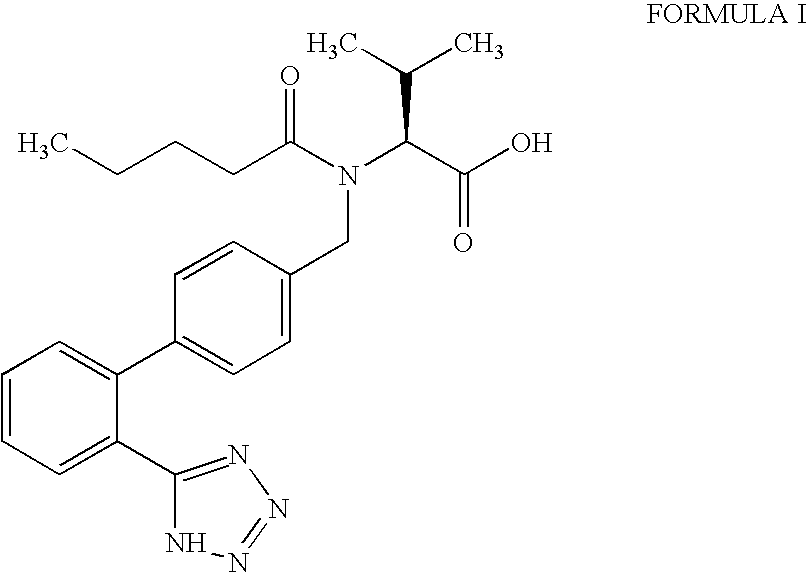

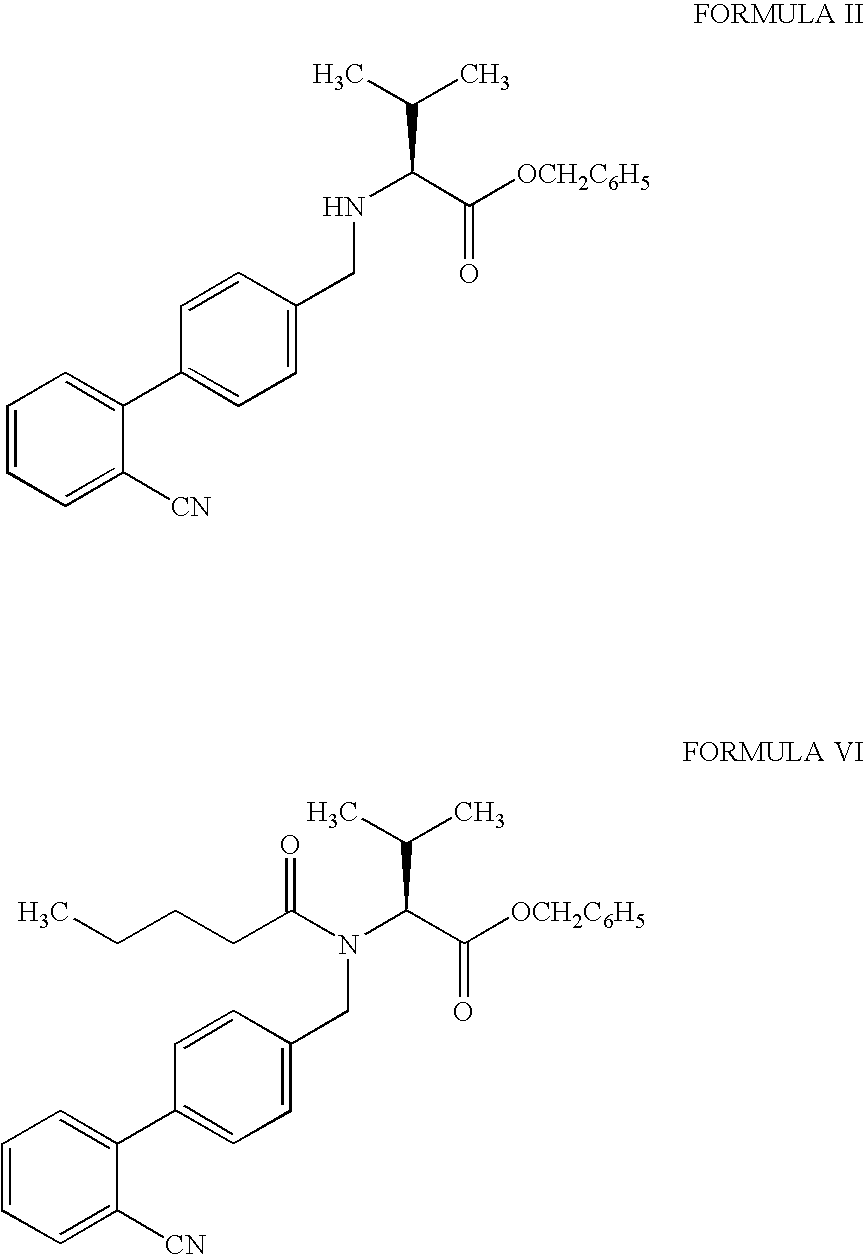

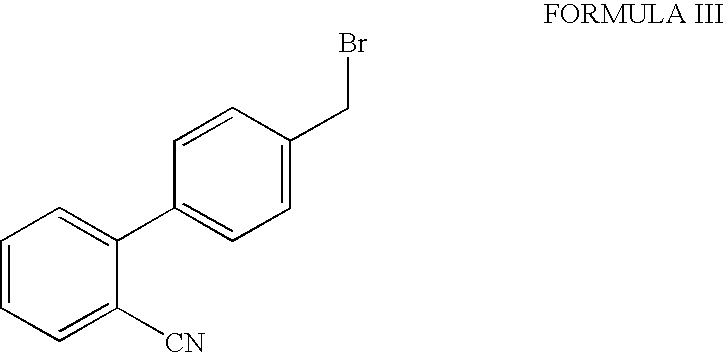

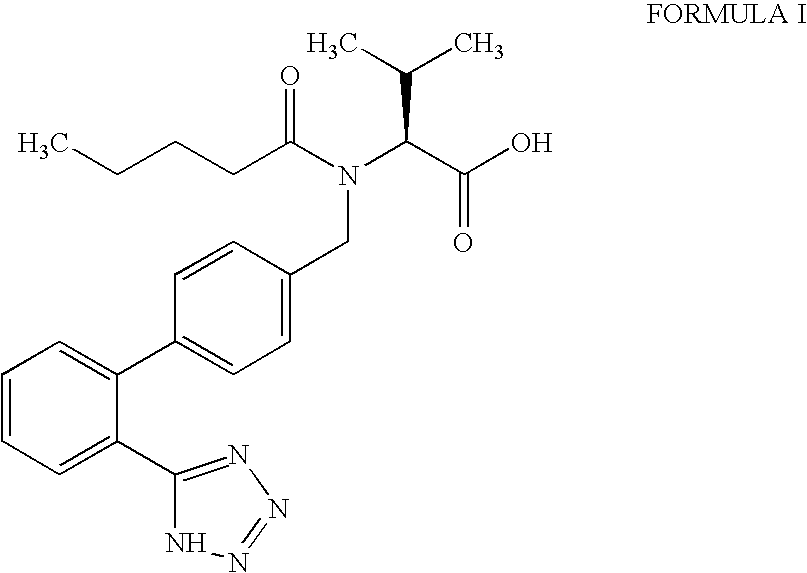

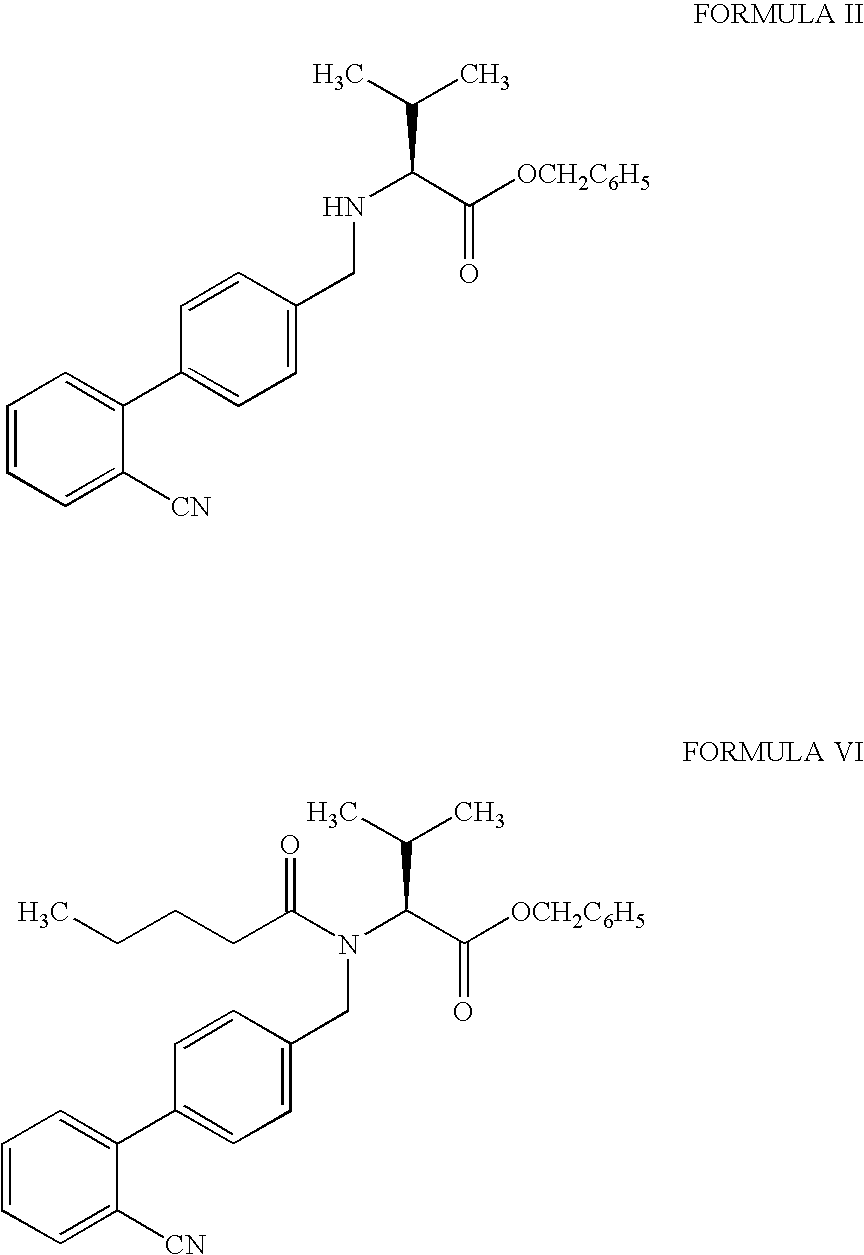

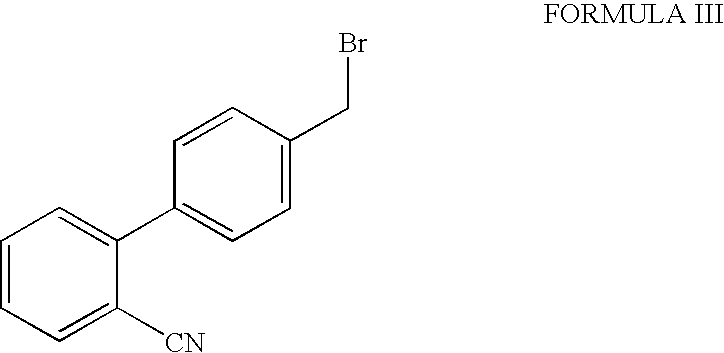

Processes for the preparation of intermediates of valsartan

InactiveUS20090203921A1Minimizing chanceMinimize formationOrganic chemistryValsartanOrganic chemistry

Owner:RANBAXY LAB LTD

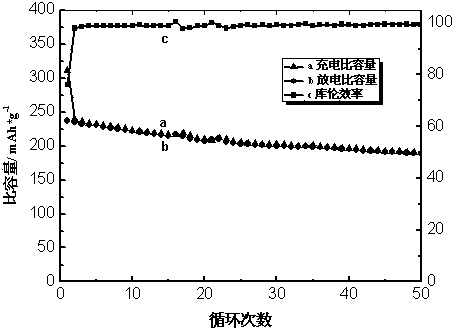

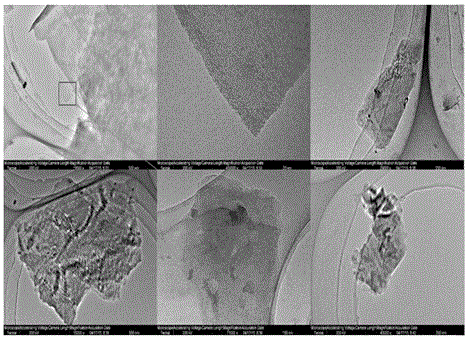

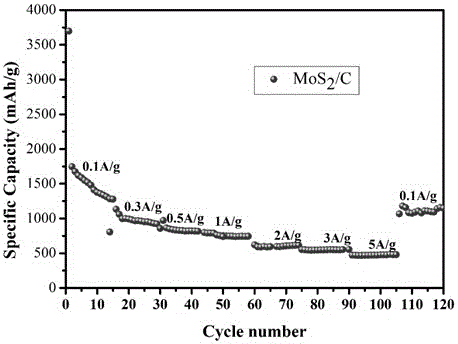

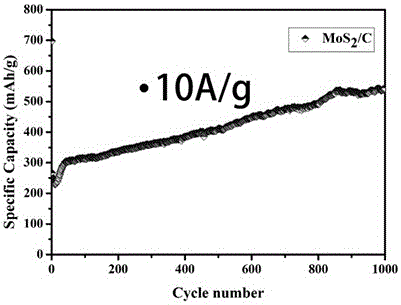

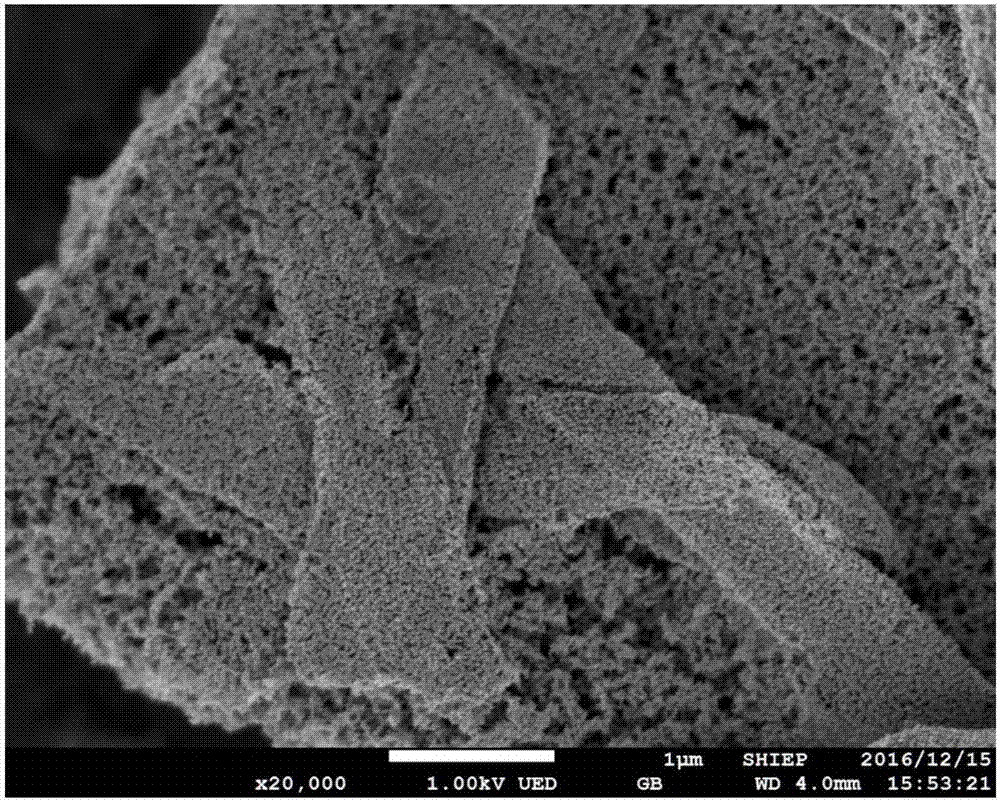

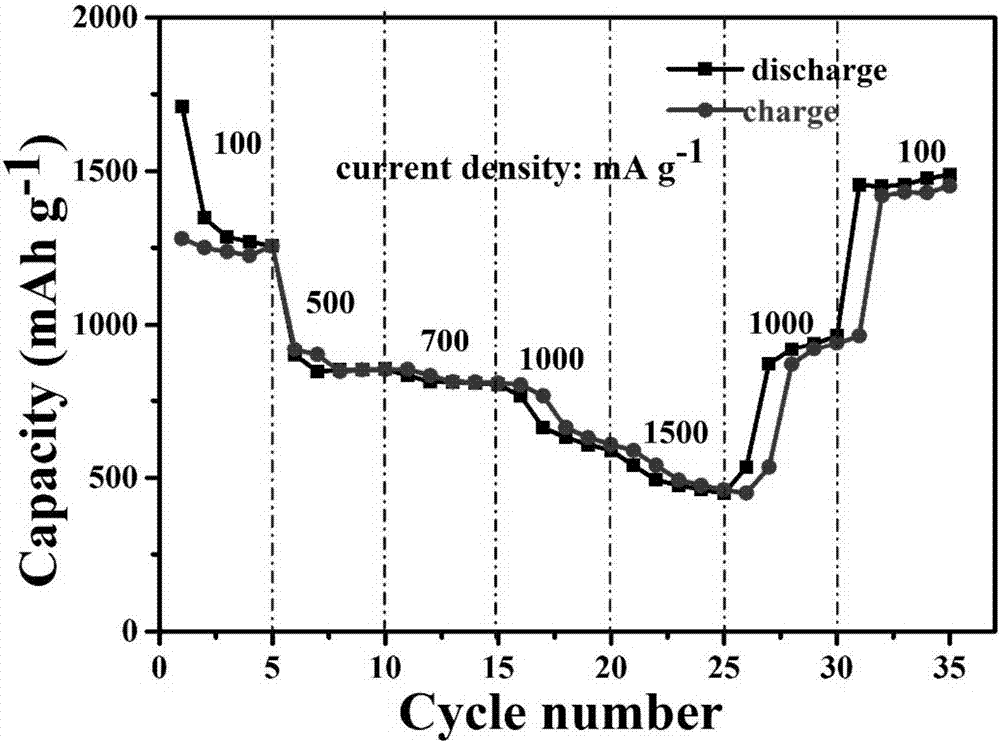

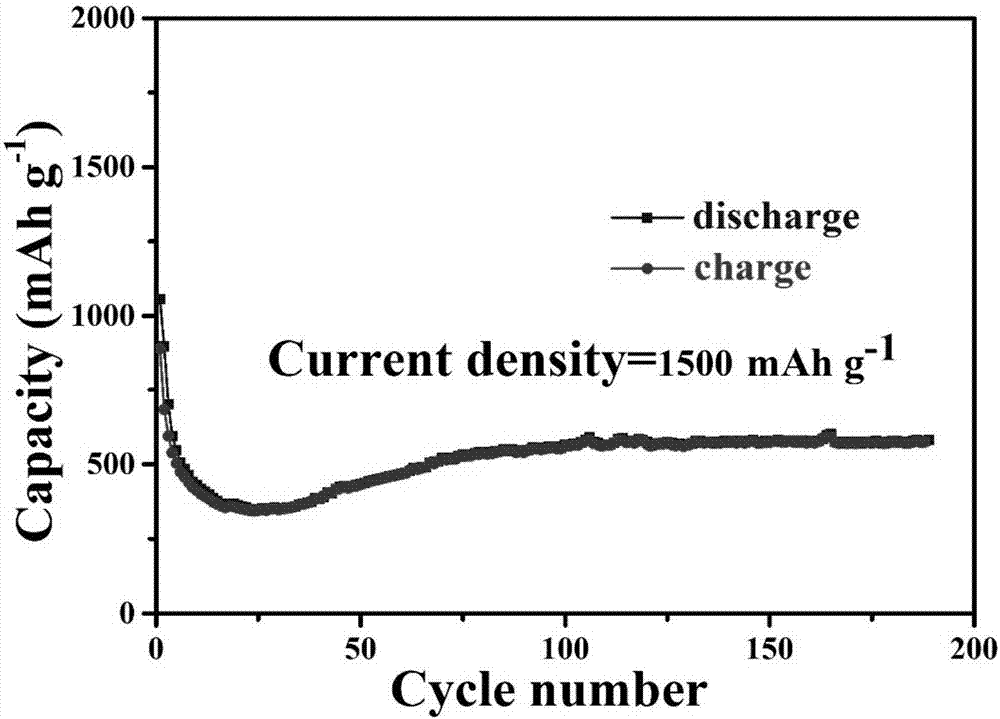

Preparation method of negative electrode active material for lithium-ion battery

ActiveCN105870411ASimple methodSuitable for industrial scaleCell electrodesSecondary cellsPorous carbonElectrical battery

The invention provides a preparation method of a negative electrode active material for a lithium-ion battery. The method comprises the following steps: dissolving nonionic polysaccharide into a water solution, adding a certain amount of graphene-like transition metal disulphide, carrying out ultrasonic dispersing and stripping for a period of time and then centrifuging the solution to obtain a disperse solution of the non-ionic polysaccharide / graphene-like transition metal disulphide; carrying out freeze drying, roasting the product in a nitrogen atmosphere for a certain period of time, taking out the product, alloying and grinding the product and potassium hydroxide, and then burning and activating the mixture in the nitrogen atmosphere to obtain the graphene-like transition metal disulphide / porous carbon material. The graphene-like transition metal disulphide / porous carbon material is applied as the negative electrode material for the lithium-ion battery. The graphene-like transition metal disulphide is stripped through the non-ionic polysaccharide, so that the method is green, simple and effective; and meanwhile, the obtained graphene-like transition metal disulphide / porous carbon material is suitable for the negative electrode material for the lithium-ion battery, excellent in performance and beneficial to industrial production and application.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of trace Mo-doped lamellar lithium-enriched ternary positive electrode material

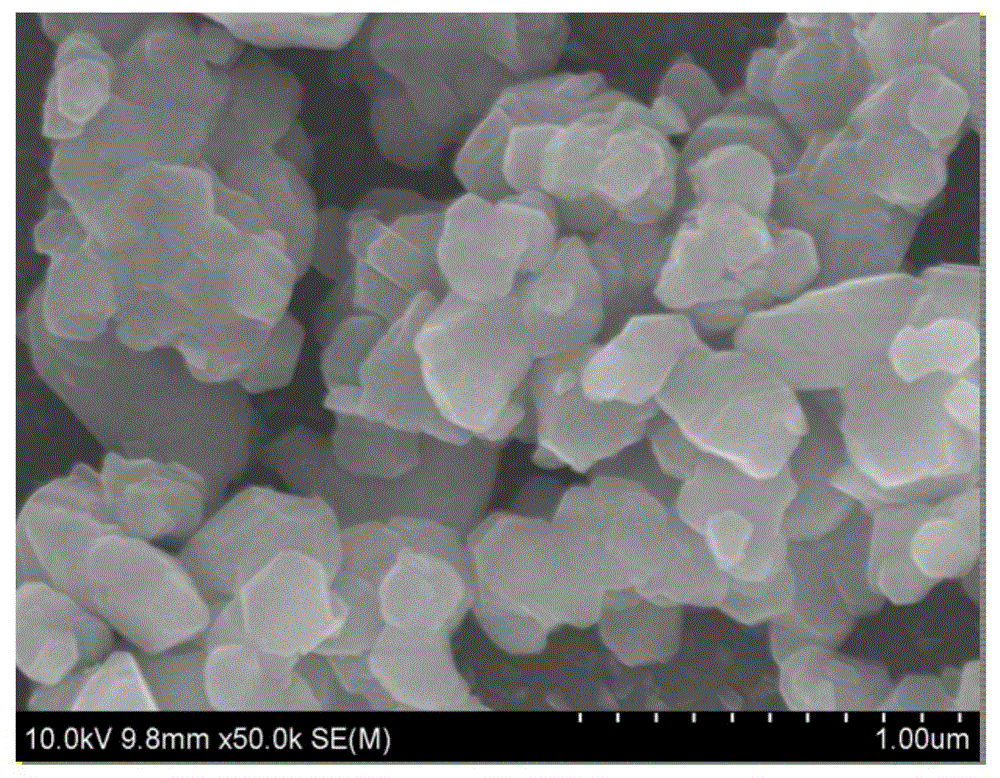

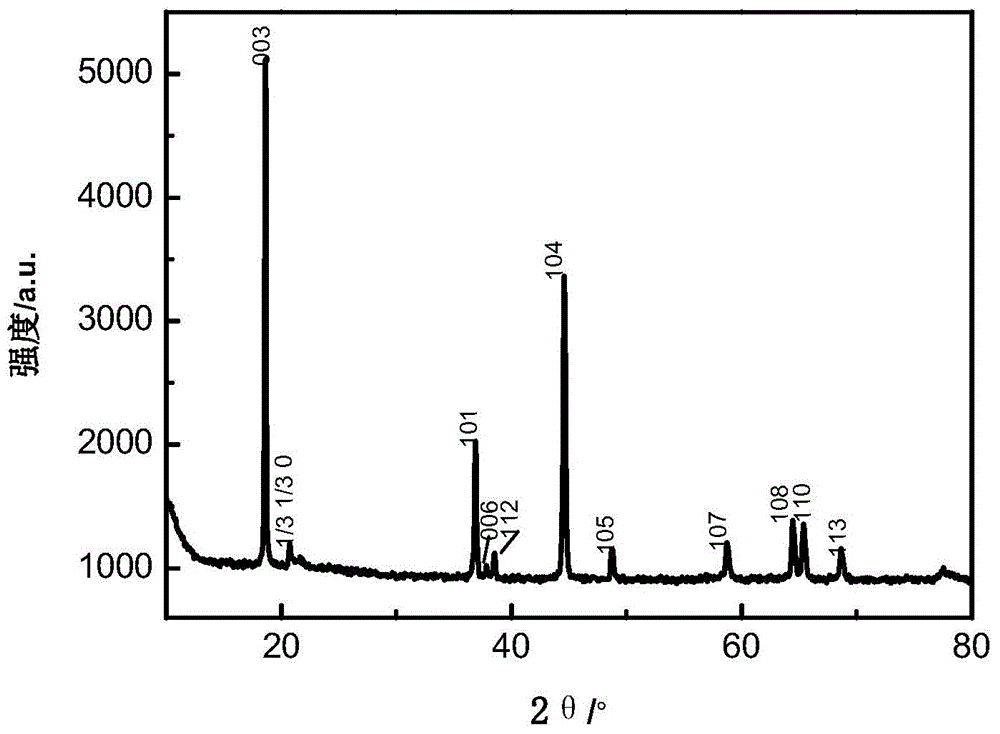

InactiveCN104900857AHigh crystallinityExcellent electrochemical performanceCell electrodesTube furnaceNickel salt

The invention relates to a preparation method of a trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The molecular formula of the prepared ternary positive electrode material is Li1.2(Mn0.54Ni0.13Co0.13)(1-x)MoxO2 (x is more than 0 and smaller than 1). The adopted preparation method is an organic co-precipitation method and comprises the steps of stirring an organic precipitator in a water bath with constant temperature, and dissolving the organic precipitator into an organic solvent so as to obtain a solution A; then dissolving soluble cobalt salt, nickel salt, manganese salt, molybdenum salt and lithium salt into deionized water to obtain a solution B; after thorough dissolution, dropwise adding the solution B into the solution A at a constant speed, reacting and drying, increasing the temperature of the obtained solid powder in a high-temperature tube furnace system, and calcining so as to obtain the trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The material has uniform particles and regular polygonal morphology feature, and has relatively good electrochemical performance, the preparation process is relatively simple, and the ternary positive electrode material is suitable for industrialized scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

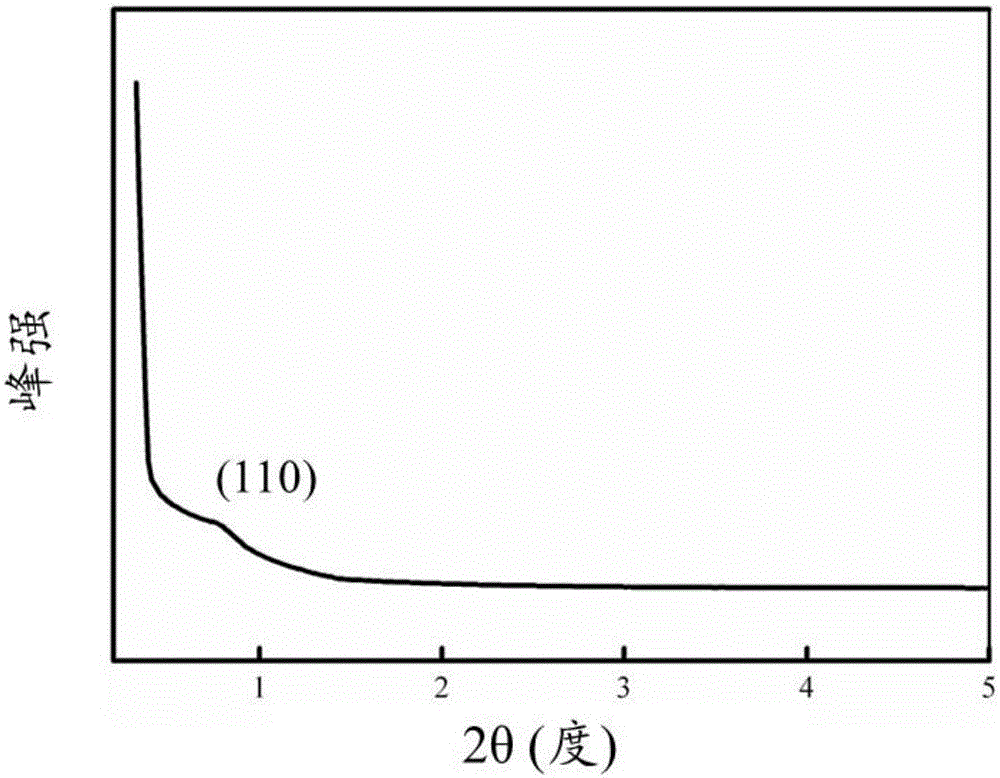

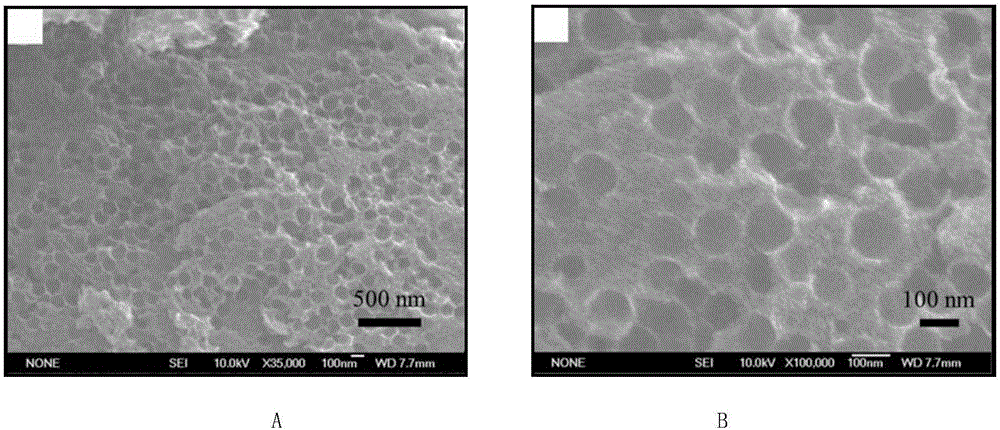

Preparation method of conductive carbon material with hierarchical porous structure, and pole plate for lead acid battery

InactiveCN106784847AReduce concentration polarizationLower internal resistanceLead-acid accumulatorsLead-acid accumulator electrodesMuffle furnaceSurface-active agents

The invention provides a preparation method of a conductive carbon material with a hierarchical porous structure. The method comprises: dissolving phenolic resin into an ethanol solution; dissolving a surface active agent F127 into an HCl-containing ethanol solution; then adding ethyl orthosilicate, silicon dioxide colloidal particles and the phenolic resin ethanol solution; transferring a mixture into a container, volatilizing ethanol, performing thermal polymerization in a reaction furnace of 100 DEG C to obtain a faint-yellow transparent thin film, and grinding the thin film into powder; putting the powder into a tubular muffle furnace, and performing carbonization under the nitrogen atmosphere protection; soaking a hierarchical porous structure carbon / silicon oxide composite material into HF of which the content is 5wt%, removing silicon oxide, only retaining carbon components of the hierarchical porous structure, washing a sample by using deionized water, and then performing drying to obtain the conductive carbon material with the hierarchical porous structure. According to the preparation method of the conductive carbon material with the hierarchical porous structure, the internal resistance of a lead acid battery electrode can be effectively reduced, and the utilization rate of active substances and the charge-discharge rate are improved; meanwhile, the electrode structure can be stabilized, and the recycling life is prolonged.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

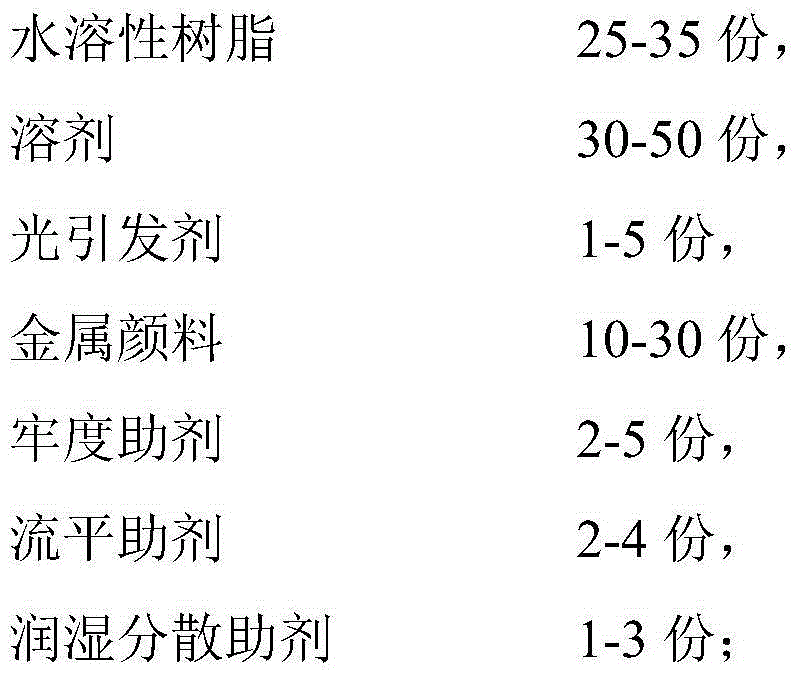

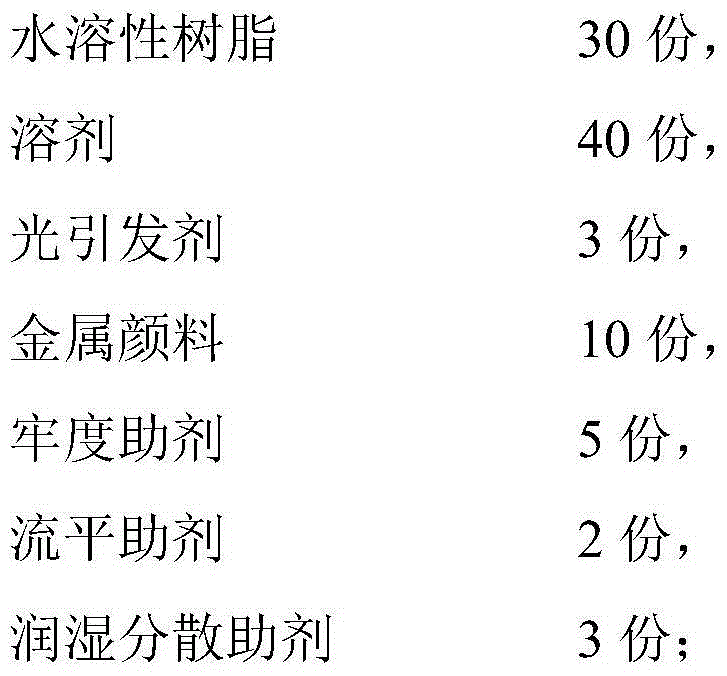

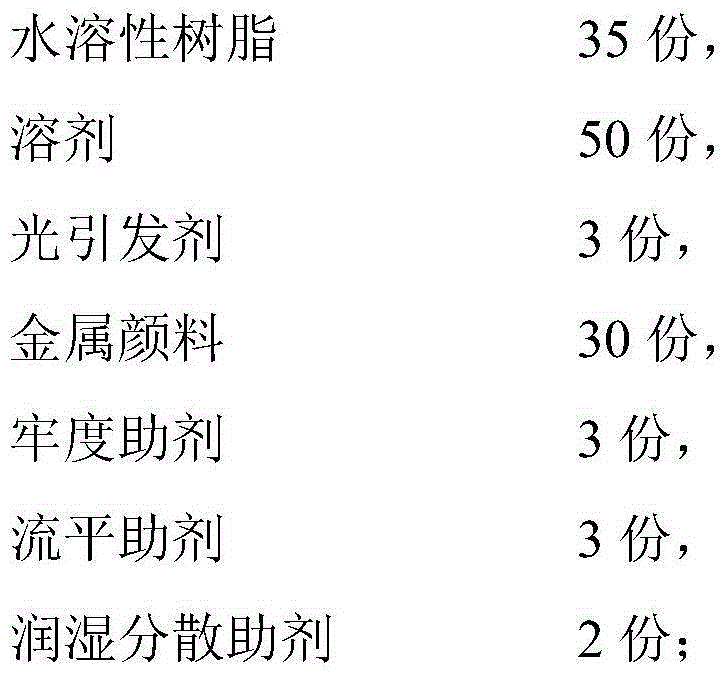

Water-based metal ink for UV offset ink and preparation method thereof

The invention relates to a water-based metal ink for UV offset ink and a preparation method thereof. The water-based metal ink comprises the following components by weight: 25-35 parts of water soluble resin, 30-50 parts of a solvent, 1-5 parts of a photoinitiator, 10-30 parts of a metallic pigment, 2-5 parts of a fastness assistant, 2-4 parts of a leveling assistant and 1-3 parts of a wetting and dispersing assistant. Specifically, the solvent is a mixed solvent of deionized water and ethanol in a mass ratio of 1:1, the metallic pigment is bronze powder or aluminum silver powder. The preparation method includes: firstly fully mixing the metallic pigment with the solvent evenly, then adding water soluble resin, the photoinitiator and assistants in order, stirring the materials fully till uniform dispersion, then carrying out filling, sealing and packaging, and performing aluminum foil sealing, thus obtaining the water-based metal ink finished product. Compared with the prior art, the water-based metal ink provided by the invention is green and environment-friendly, has the advantages of good binding fastness with UV offset ink, difficult fall, simple preparation process, good finished product stability, and production cost saving, and is suitable for industrial scale and high efficiency production.

Owner:SHANGHAI HUIBAI FINE CHEM CO LTD

Preparation method of anode material for lithium ion batteries

ActiveCN107381656AThe synthesis method is simpleHigh specific capacityCell electrodesSecondary cellsAir atmosphereSodium-ion battery

The invention provides a preparation method of an anode material for lithium ion batteries. The preparation method comprises the following steps: dissolving metal salt of zinc ions and cobalt ions, then adding a certain amount of a polar solvent containing 8-hydroxyquinoline, after mixing and stirring, standing at room temperature, centrifuging and drying the mixture to obtain a metal organic compound of zinc-cobalt-8-hydroxyquinoline, then putting the obtained metal organic compound into a tubular furnace, calcining in an air atmosphere, taking out the metal organic compound to obtain a layered ZnCo2O4 material, and using the layered ZnCo2O4 material into the anode material for lithium ion batteries. The metal organic compound of zinc-cobalt-8-hydroxyquinoline is synthesized in the solution, and then the layered ZnCo2O4 material is obtained through calcinations, so that the method is simple and convenient in synthesis and is effective, the obtained layered ZnCo2O4 material can serve as the anode material for lithium ion batteries, the anode material is excellent in electrochemical performance and can be applicable for industrial production and practical application.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

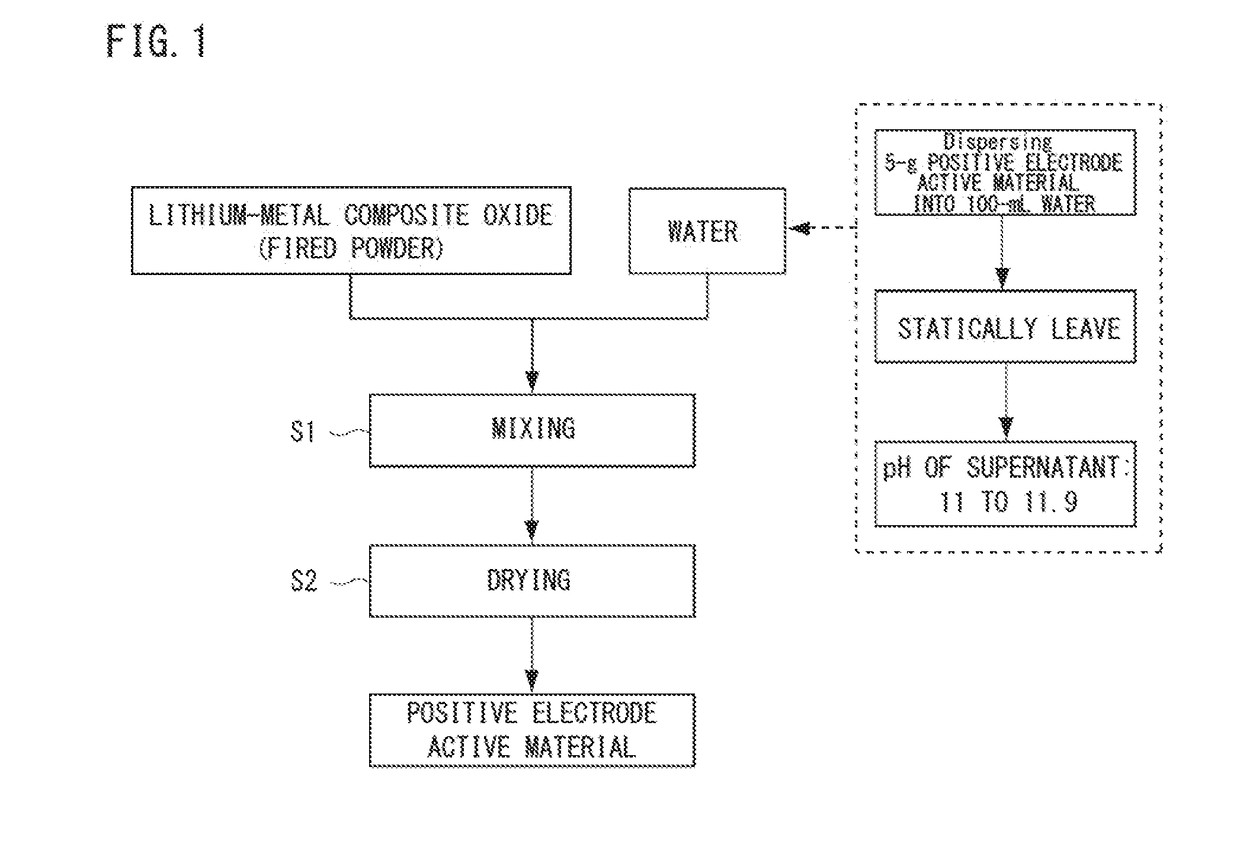

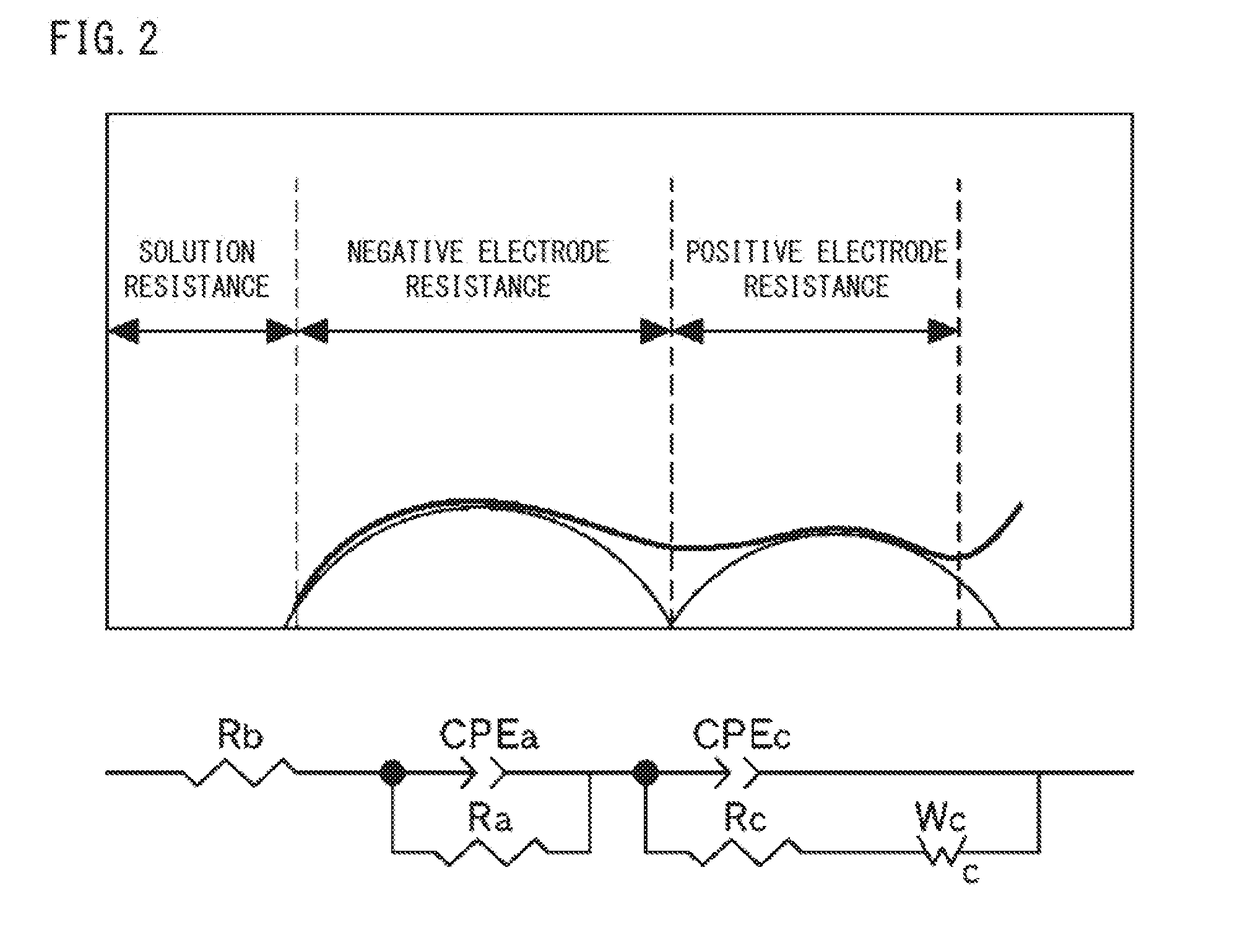

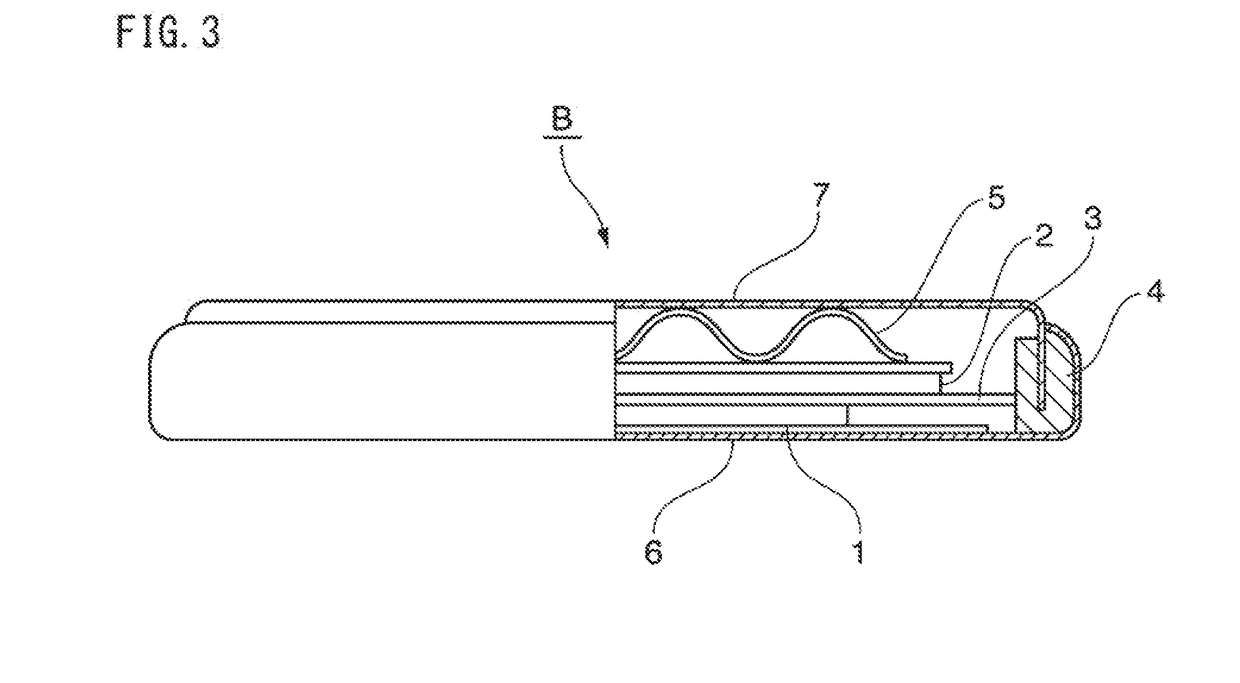

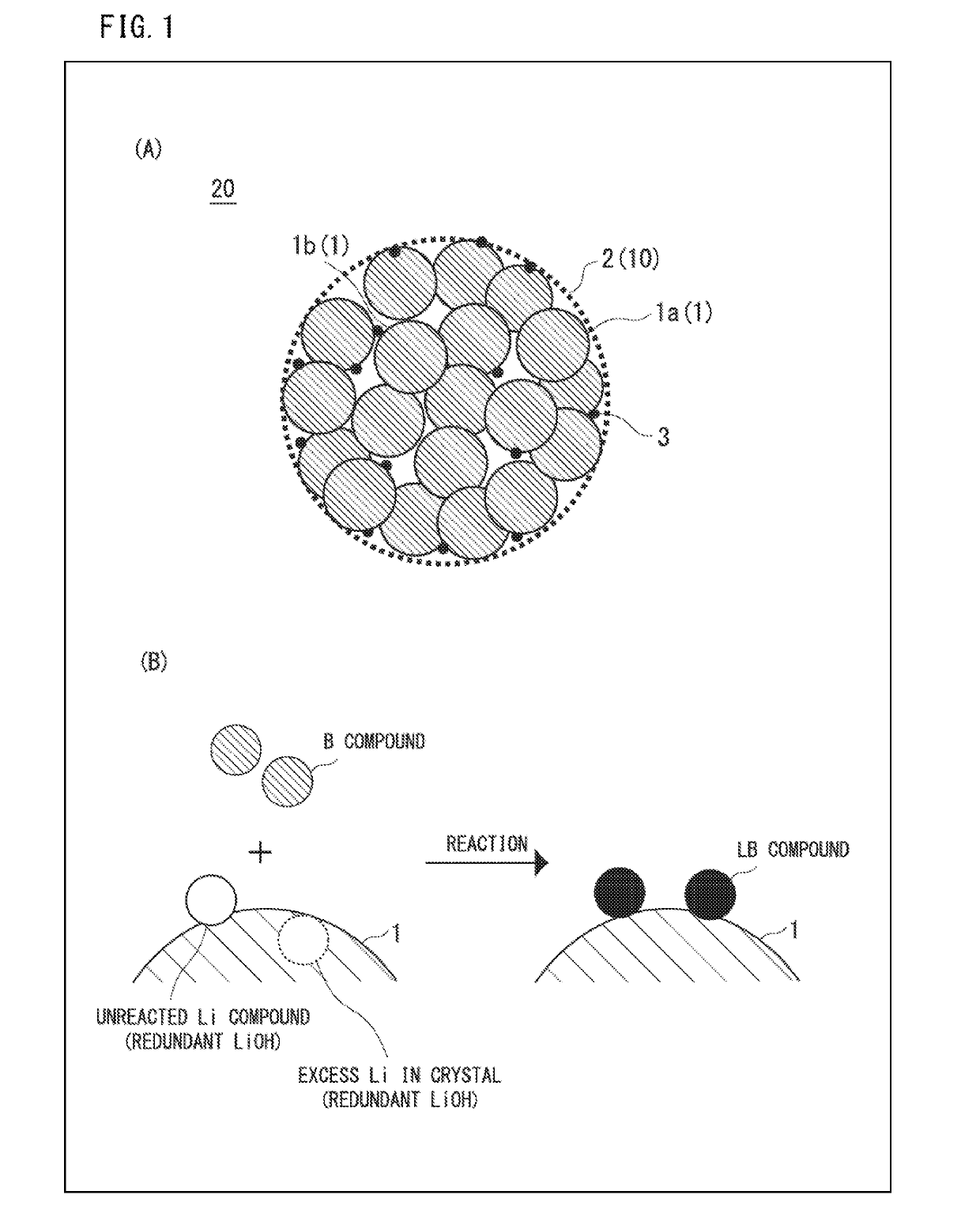

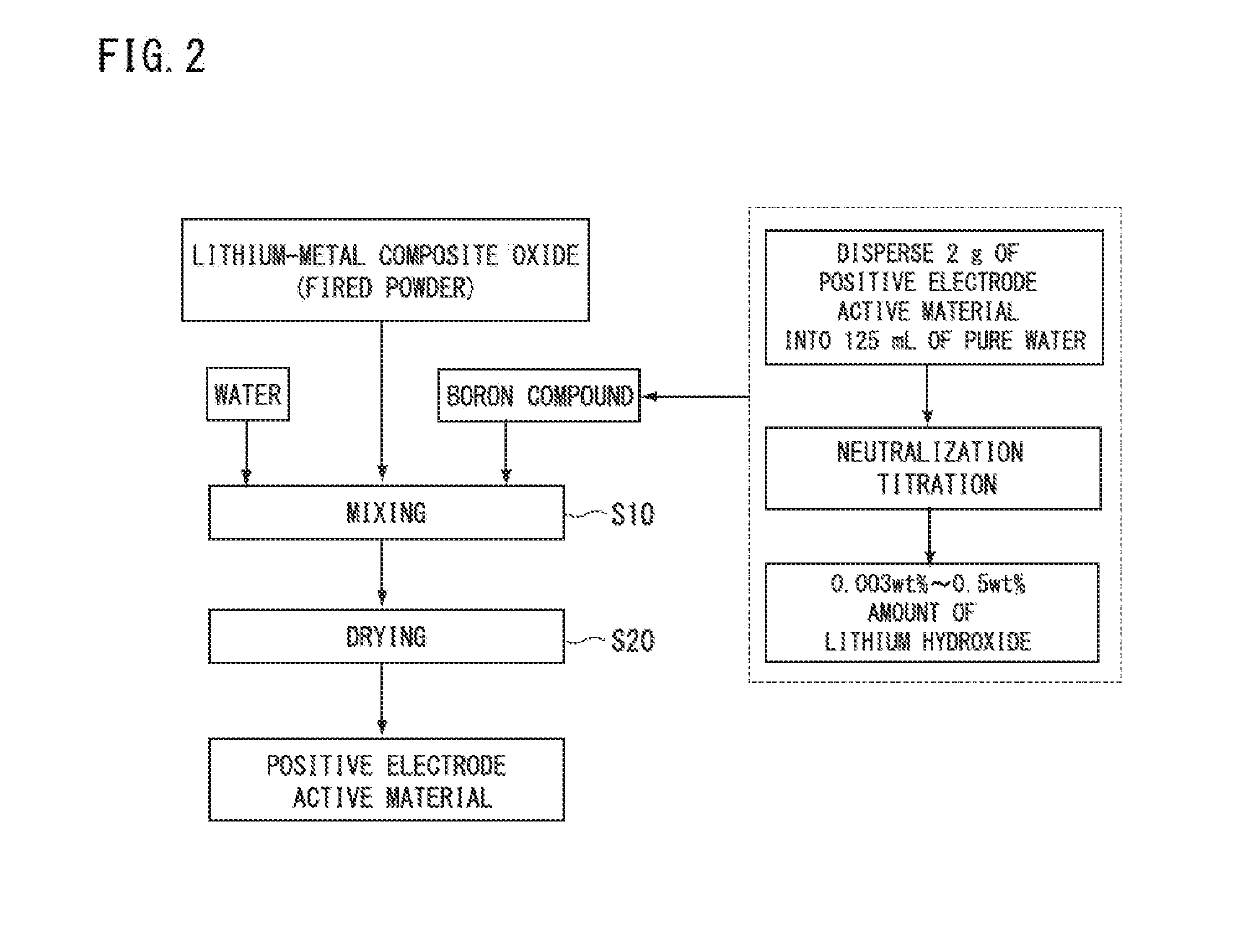

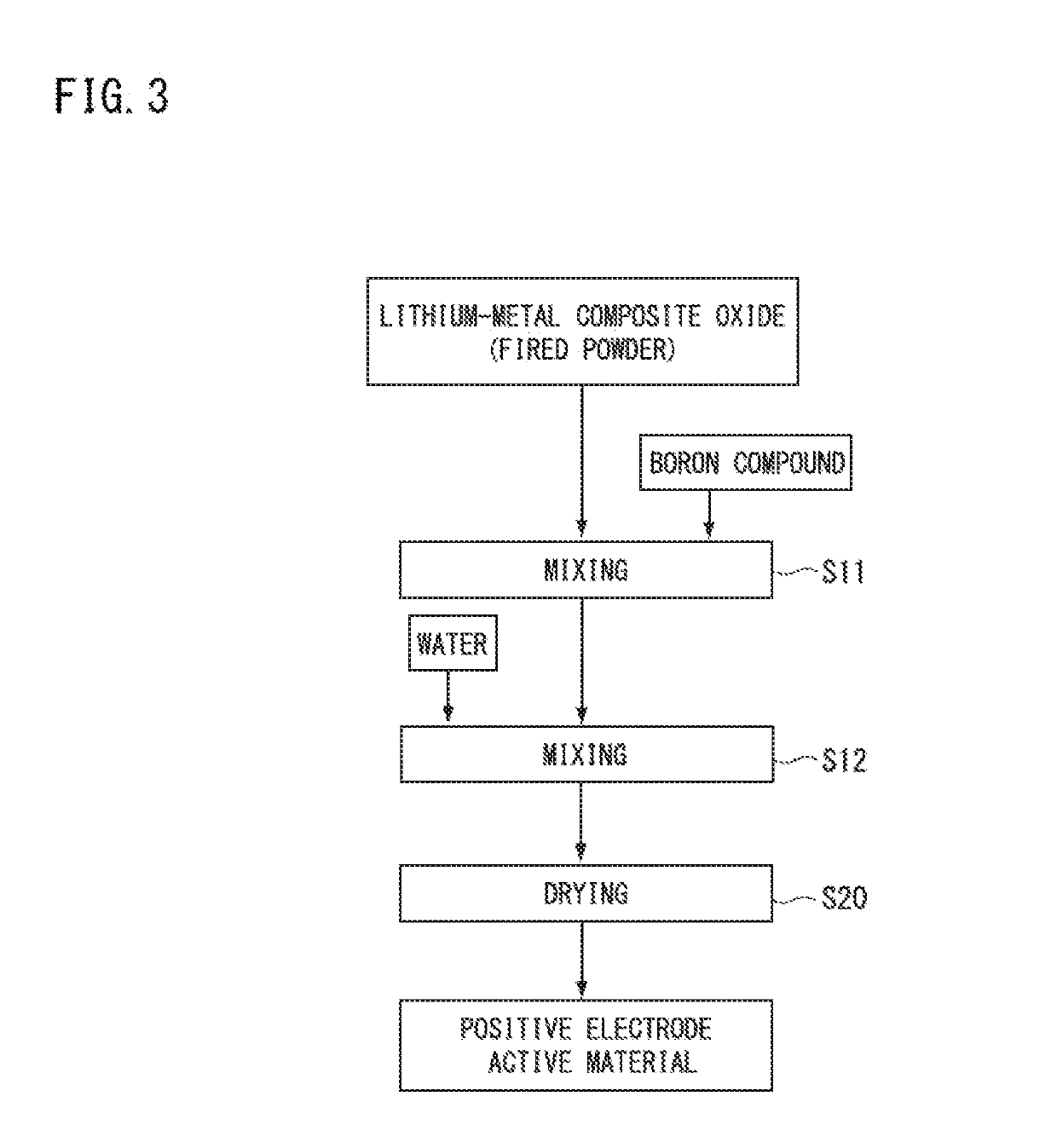

Positive electrode active material for non-aqueous electrolyte secondary battery and method for manufacturing the same, positive electrode mixed material paste for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

PendingUS20190051929A1Improve stabilityImprove featuresElectrode thermal treatmentPositive electrodesLithium metalCrystal structure

The present invention has an object to provide a positive electrode active material for a non-aqueous electrolyte secondary battery which can improve stability of a positive electrode mixed material paste when manufacturing the secondary battery and can increase the battery capacity and improve output characteristic of the secondary battery. A method for manufacturing a positive electrode active material for a non-aqueous electrolyte secondary battery includes mixing fired powder containing lithium-metal composite oxide having a crystal structure of a layered structure with water, and drying this mixture. The fired powder includes secondary particles formed by agglomeration of primary particles. Water is mixed thereto with an amount with which pH of a supernatant obtained after 5 g of the positive electrode active material is dispersed into 100 mL of pure water followed by statically leaving the dispersion solution for 10 minutes falls within a range of 11 to 11.9 at 25° C.

Owner:SUMITOMO METAL MINING CO LTD

In-situ SiC particle reinforced Ti6Al4V preparation method

The invention discloses an in-situ SiC particle reinforced Ti6Al4V preparation method. The method comprises the following steps: (1) putting Si powder and C powder into high-energy grinding equipment for mechanical alloying, grinding for 8-48 hours, wherein the mass ratio of the Si powder to the C powder is (2-3):1, then adding SiO2 powder which accounts for 5-20% of the total mass of the Si powder and the C powder, and further grinding for 4-10 hours to obtain a mixed material; (2) uniformly mixing titanium powder, master alloy powder and the mixed material, wherein the addition amount of the titanium powder accounts for 80-95% of the total mass of the titanium powder and the master alloy powder, the addition amount of the master alloy powder accounts for 5-20% of the total mass of the titanium powder and the master alloy powder, the addition amount of the mixed material accounts for 5-40% of the titanium powder and the master alloy powder, and compression molding to produce blanks; and (3) sintering the blanks in a vacuum sintering furnace for two stages at 700-900 DEG C for 0.5-3 hours, then heating to be 1300-1500 DEG C and sintering in an argon atmosphere for 0.5-3 hours. The reinforcement phase of a composite material obtained by the method is produced in situ, interfaces are densely connected together, and the composite material has high strength and is suitable for industrial scale.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Novel method for producing nanocapsules in the absence of an organic solvent, and nanocapsules produced thereby

InactiveUS20130207286A1Easy to carrySuitable for industrial scaleLiposomal deliveryMicroballoon preparationOrganic solventHydrophobic polymer

A method for preparing an aqueous suspension of nanocapsules comprising an oily core surrounded by a polymeric shell, comprises mixing first and second phases, wherein the first oily phase comprises a hydrophobic polymer, an oil or a mixture of oils, at least one active ingredient, and a surfactant TA1. The oily phase is brought to a temperature T1 higher than the melting point of the hydrophobic polymer, the hydrophobic polymer being miscible, at this temperature T1, with the mixture of the surfactant TA1 and the oil or mixture of oils, and the active ingredient being miscible, soluble or solubilized in the mixture of the surfactant TA1 and the oil or mixture of oils. The second polar phase comprises a hydrophilic polymer in the form of a hydrogel in an aqueous solution containing a surfactant TA2, to form the nanocapsules in an aqueous suspension.

Owner:UNIV CLAUDE BERNARD LYON 1

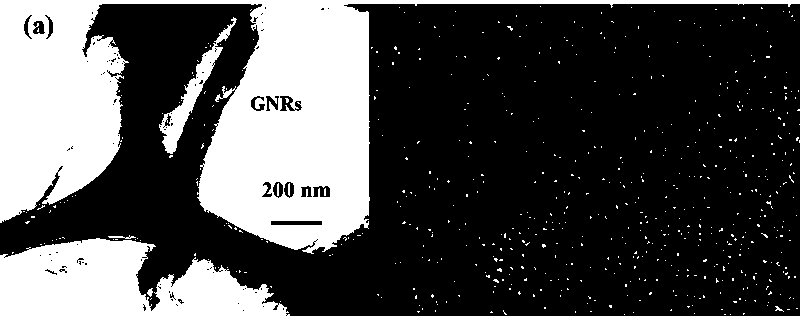

Boron-doped graphene nanobelt loaded nickel monatomic catalyst and preparation method thereof

InactiveCN110860291AImprove catalytic performanceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesDoped graphenePtru catalyst

The invention relates to a boron-doped graphene nanobelt loaded nickel monoatomic catalyst and a preparation method thereof. The boron-doped graphene nanobelt loaded nickel monoatomic catalyst is prepared by comprising the following steps: preparation of a graphene nanobelt, preparation of a boron-doped graphene nanobelt and preparation of the boron-doped graphene nanobelt loaded nickel monoatomiccatalyst. Compared with the prior art, the boron-doped graphene nanobelt loaded nickel monoatomic catalyst provided by the invention uses the boron-doped graphene nanobelt as a belt-shaped carrier, has uniform and regular nickel monatomic morphology characteristics, has good catalytic performance and stability in the field of hydrogen production, is simple in preparation process, is applicable toindustrial production and has high economic value.

Owner:塞文科技(上海)有限公司

Process for producing 2,3,3,3-tetrafluoropropene

ActiveUS20150259266A1High selectivityCatalyst deterioration can be suppressedPreparation by hydrogen halide split-offMicrobiological testing/measurementHydrogen fluoridePolymer science

This invention provides a process for producing 2,3,3,3-tetrafluoropropene, the process comprising: (1) a first reaction step of reacting hydrogen fluoride with at least one chlorine-containing compound selected from the group consisting of a chloropropane represented by Formula (1): CClX2CHClCH2Cl, wherein each X is the same or different and is CI or F, a chloropropene represented by Formula (2): CClY2CCl═CH2, wherein each Y is the same or different and is CI or F, and a chloropropene represented by Formula (3): CZ2═CClCH2Cl, wherein each Z is the same or different and is CI or F in a gas phase in the absence of a catalyst while heating; and (2) a second reaction step of reacting hydrogen fluoride with a reaction product obtained in the first reaction step in a gas phase in the presence of a fluorination catalyst while heating. According to the process of this invention, 2,3,3,3-tetrafluoropropene (HFO-1234yf) can be obtained with high selectivity, and catalyst deterioration can be suppressed.

Owner:DAIKIN IND LTD

Preparation method of rice hull stacked porous silicon carbide

The invention discloses a preparation method of rice hull stacked porous silicon carbide. The preparation method comprises the following steps: (1) soaking rice hulls in phenolic resin, filtering and drying; (2) stacking and forming the soaked, filtered and dried rice hulls in a container so as to obtain a stacked product; (3) carbonizing the stacked product in a vacuum furnace so as to obtain a carbonized product; (4) putting the carbonized product in a crucible, transferring to the vacuum furnace, and carrying out silicification so as to obtain rice hull stacked porous silicon carbide. The preparation method is characterized in that the agricultural wastes, namely the rice hulls are used as raw materials, soaked in the phenolic resin, filtered, dried, then stacked and formed; the stacked product is subjected to carbonization and silification in the vacuum furnace so as to obtain the porous or foam silicon carbide ceramic with porosity of 30-70%. The preparation method changes waste materials into things of value and belongs to the field of green ceramic. The obtained porous silicon carbide ceramic is high in porosity, adjustable in porosity, simple in method and suitable for industrial scale.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Process for the production of aromatic amines by heterogeneously catalysed hydrogenation

InactiveUS7193112B2Efficient use ofIncreased space-time yieldOrganic compound preparationOrganic chemistry methodsNitro compoundHomogeneous catalysis

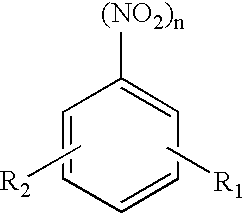

The invention describes a process for the production of aromatic amines by the catalytic hydrogenation of aromatic nitro compounds, with the process being characterized by at least one catalytic hydrogenation step and the catalyst consists at least of a monolithic support and a catalytically active coating.

Owner:BAYER MATERIALSCIENCE AG

Positive electrode active material for non-aqueous electrolyte secondary battery and method for manufacturing the same, positive electrode mixed material paste for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

ActiveUS20190165360A1Prevent gelationImprove stabilityElectrode thermal treatmentSecondary cellsLithium hydroxideMixed materials

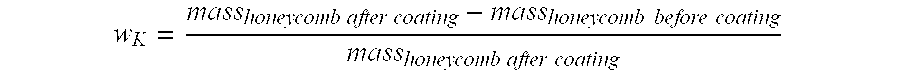

The present invention has an object to provide a positive electrode active material for a non-aqueous electrolyte secondary battery which not only suppresses gelation of a positive electrode mixed material paste upon producing the non-aqueous electrolyte secondary battery but also improves the stability thereof. Provided is the positive electrode active material represented by general formula LisNi1−x−y−zCoxMnyMzO2+α (0≤x≤0.35, 0≤y≤0.35, 0≤z≤0.10, 0.95≤s≤1.30, and 0≤α≤0.2, and M represents at least one element selected from V, Mg, Mo, Nb, Ti, W, and Al) and containing secondary particles formed by agglomeration of primary particles, wherein at least part of the surface of the primary particles thereof is covered with a lithium boron compound, and the amount of redundant lithium hydroxide of the positive electrode active material measured with a neutralization titration is at least 0.003% by mass and up to 0.5% by mass relative to the total of the positive electrode active material.

Owner:SUMITOMO METAL MINING CO LTD

Graphene nanobelt supported palladium monatomic catalyst and preparation method thereof

InactiveCN110665497AImprove catalytic performanceImprove stabilityMaterial nanotechnologyCatalyst activation/preparationPtru catalystGraphene nanoribbons

The invention relates to a graphene nanobelt supported palladium monatomic catalyst and a preparation method thereof. The preparation method comprises steps of preparation of graphene nanobelts and preparation of palladium monatomic, and preparation of the graphene nanobelt supported palladium monatomic catalyst. Compared with the prior art, the preparation method has the advantages that the graphene nanoribbons are used as the ribbon-shaped carriers, the palladium monatomic morphology characteristics are uniform and regular, the catalyst has good catalytic performance and stability in the field of hydrogen production, the preparation process is simple, and the catalyst is suitable for industrial production and has high economic value.

Owner:塞文科技(上海)有限公司

Process for conducting an organic reaction in ionic liquids

InactiveUS8067644B2High yieldSuitable for industrial scaleOrganic compound preparationCarbonyl compound preparationMesityl oxideCyclohexene

Owner:PROCTER & GAMBLE CO

Processes for the preparation of intermediates of valsartan

Owner:RANBAXY LAB LTD

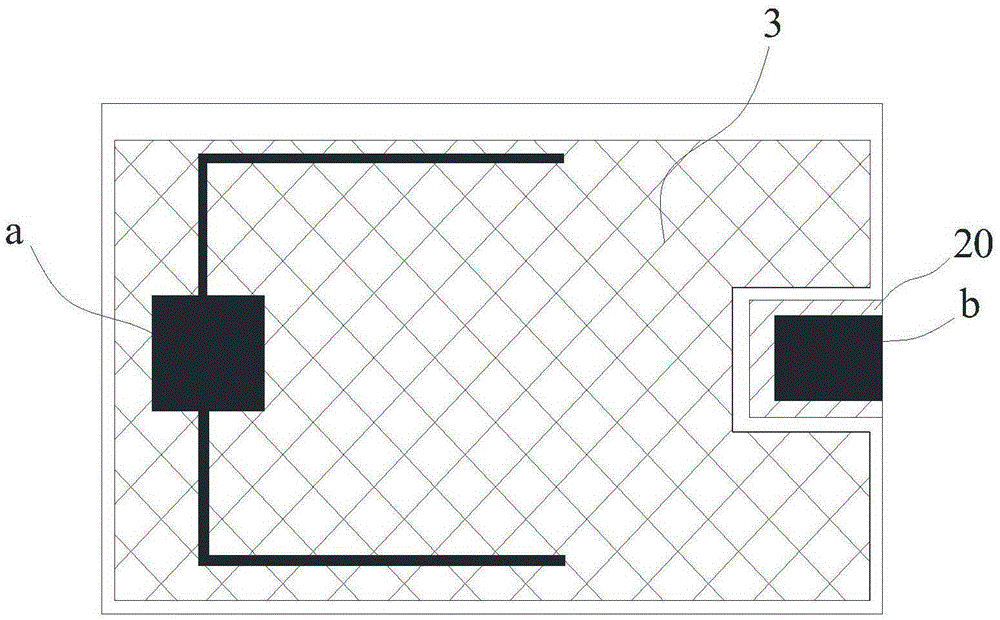

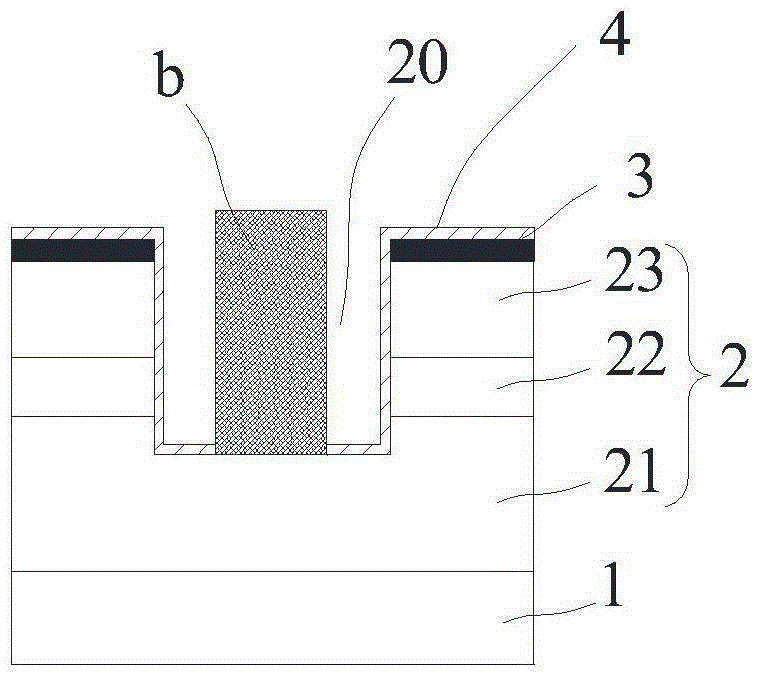

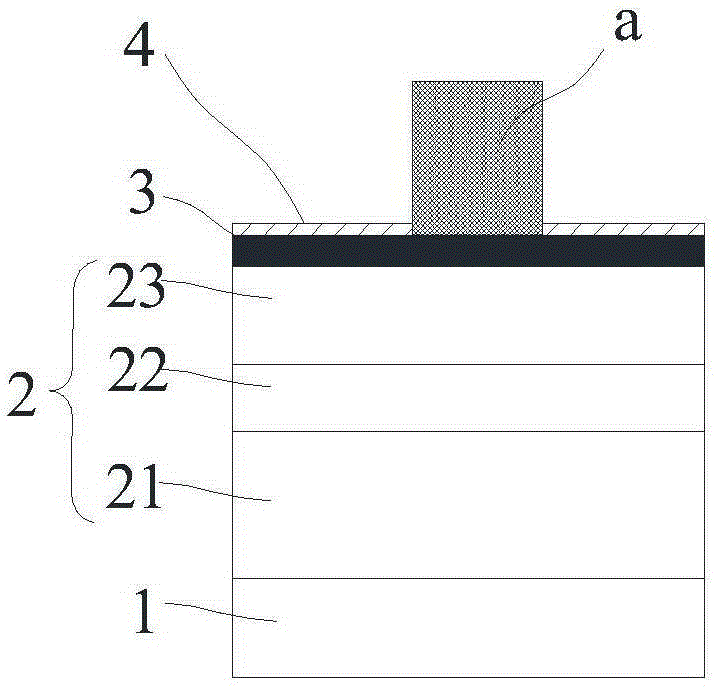

Light emitting diode chip and preparation method of the same

ActiveCN106816507AExtended service lifeSimple structureSemiconductor devicesFilling materialsCrystallographic defect

The invention provides a light emitting diode (LED) chip and a preparation method of the same, for solving the problems that because of crystal defect, static puncture or other situations, electric leakage may occur in a current light emitting diode chip, so that the LED chip is disabled. The light emitting diode chip includes a substrate, an epitaxial lamination layer, a transparent conducting layer, an N electrode and a P electrode, wherein a center groove is etched in the horizontal center line of the epitaxial lamination layer and the center groove divides the epitaxial lamination layer into two pieces; the center groove is filled with insulating filling materials; and the transparent conducting layer does not cover the center groove and an electrode groove. The light emitting diode chip has the advantages of improving the service life, improving the reliability of an LED device using the light emitting diode chip, being very simple in structure, and being suitable for industrial scale development.

Owner:广东比亚迪节能科技有限公司

Preparation method of pinenut kernel cake

InactiveCN108095003AEasy to prepareThe preparation process is simple and controllableFood shapingPolyesterGlycollic acid

The invention discloses a preparation method of pinenut kernel cake. According to the method, firstly, pinenut kernels are soaked in water and are crushed together with water; drying is performed; soft particles with the fine particle diameter are obtained; aliphatic polyester is added; ethanol is used as a medium; the aliphatic polyester and the pinenut kernels realize sufficient contact; under the existence of certain moisture, the aliphatic polyester hydrolyzes to obtain glycollic acid and are seeped into tissues in the pinenut kernels; unsaturated fatty acid is combined to be seeped to theoutside of the pinenut kernels; meanwhile, the pinenut kernel tissues become loose and soft; hydroxypropyl methylcellulose is added; the film forming performance and the viscosity are utilized; the unsaturated fatty acid can be protected; the pinenut kernel viscosity can be enhanced; the shaping performance is improved. By using the method, the pinenut kernel cake with good mouthfeel and good shaping performance can be obtained. The preparation method also has the advantages that the preparation method is simple; the preparation process is controllable; the method is applicable to industrialization.

Owner:王艳萍

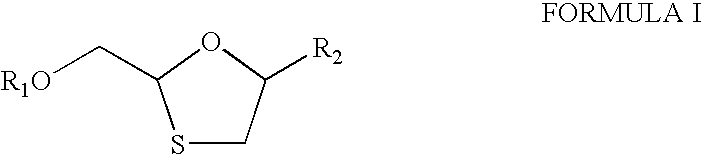

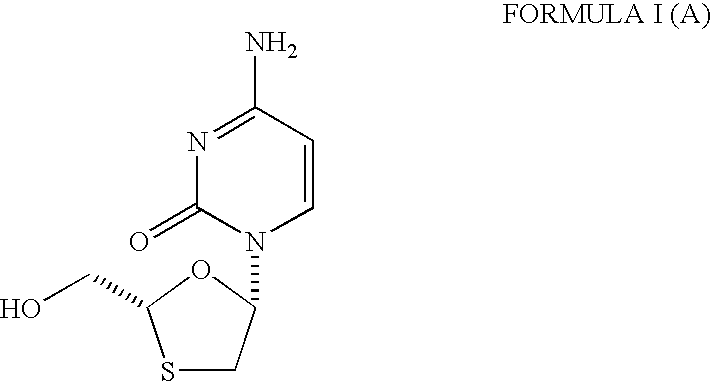

Process and intermediates for the preparation of substituted 1,3-oxathiolanes, especially lamivudine

InactiveUS20100311961A1High chemical purityHigh optical puritySugar derivativesGroup 5/15 element organic compoundsPhotochemistryLamivudine

The present invention relates to process and intermediates for the preparation of substituted 1,3-oxathiolanes. The present invention specifically relates to a process for the preparation of lamivudine.

Owner:RANBAXY LAB LTD

A kind of solvent-based metallic ink for bopp film printing and preparation method thereof

The invention relates to solvent type metal ink for BOPP thin film printing and a preparation method of the solvent type metal ink. The solvent type metal ink is prepared from, by weight, 10-30 parts of metallic pigment, 25-50 parts of solvent and 30-60 parts of film-forming resin. The metallic pigment is one of bronze powder and aluminum silver powder, the solvent is an esterified organic solvent, and the film-forming resin is nitrocotton resin. In the preparation process, the metallic pigment and the solvent are fully and evenly mixed, then the film-forming resin is added, full stirring is carried out till even dispersion is achieved, then pouring and packaging are carried out, and after aluminum foil sealing is carried out, the finished metal ink is prepared. Compared with the prior art, the prepared metal ink has good printing adaptability on BOPP, hole shrinkage or other phenomena are not likely to happen, the completeness and attractiveness of printed matter are protected, the preparation process is simple, the prepared finished product is good in stability, multiple additives do not need to be additionally added, production cost is reduced, and the method is suitable for industrial and efficient mass production.

Owner:SHANGHAI HUIBAI FINE CHEM CO LTD

Preparation method of PEST resistant composite ceramics

ActiveCN106278280AReduce manufacturing costResistance to PEST phenomenonVacuum pumpingThermal insulation

The invention discloses a preparation method of PEST resistant composite ceramics. The method comprises the following steps of (1) uniformly mixing C, Si, B, B4C and MoSi2; then, adding bonding agents; performing ball milling, material mixing, compression moulding forming and drying to obtain a blank material; (2) transferring the blank material into a vacuum sintering furnace with Si powder; maintaining the vacuum degree at 10<-2> to 10<-3> Pa; maintaining the temperature rise speed at 1 to 10 DEG C / min; then, performing heat insulation for 5 to 60min at 1400 to 1430 DEG C; then, inflating nitrogen gas or argon gas; raising the temperature to 1450 to 1500 DEG C; performing heat insulation for 5 to 60min; performing vacuum pumping; raising the temperature to 1500 to 1550 DEG C; performing heat insulation for 5 to 40min; finally performing cooling to obtain the composite ceramics. The PEST resistant composite ceramics obtained by the method have low preparation cost and are suitable for industrial mass production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of water-based tactile varnish for gravure printing and preparation method thereof

The invention relates to an aqueous touch gloss oil for gravure printing and a preparation method thereof. The aqueous touch gloss oil comprises the following components in parts by weight: 30 to 60 parts of film-forming resin, 30 to 60 parts of solvent, and 1 to 8 parts of auxiliary agent; wherein the film-forming resin is acrylic resin, the solvent is water or a mixture of water and alcohol, and the auxiliary agent is polyurethane emulsion. Compared with the prior art, the provided gloss oil belongs to aqueous resin, which has a good levelling property and film surface smoothness. The gloss oil can be well printed on the surface of various paper to protect the integrity and beautiful appearance of printed matters. The gloss oil has the advantages of beautiful appearance, stable performance, good scratch resistant performance, and good waterproof property. The film formed by the gloss oil is transparent, and thus the color and luster of medium can be more clearly displayed. The hand feeling is smooth. The preparation technology is simple, the finished product is stable, additive is not needed, the production cost is saved, and the gloss oil is suitable for industrial high-efficient massive production.

Owner:SHANGHAI JIEYISEN CO LTD

A preparation method of heteroatom-doped graphene-based material loaded noble metal nanoparticles

ActiveCN105591115BCo-dopingHigh catalytic activityMaterial nanotechnologyCell electrodesPlatinumDoped graphene

The invention provides a preparation method of heteroatom doped graphene-based material supported noble metal nanoparticles. The preparation method comprises steps as follows: preparation of a heteroatom doped graphene-based material: a graphene-based material is subjected to ultrasonic treatment, a heteroatom precursor is added, heteroatom doping is performed in a hydrothermal kettle at the temperature of 150-200 DEG C, and the heteroatom doped graphene-based material is obtained; preparation of the heteroatom doped graphene-based material supported noble metal nanoparticles: the heteroatom doped graphene-based material is dissolved in deionized water and subjected to ultrasonic treatment, a stabilizer and a metal precursor are added, metal in the metal precursor is platinum, palladium, gold or silver, the mixture is continuously stirred, pH is adjusted to range from 8 to 14, a reduction agent is added, the mixture is continuously stirred, and the heteroatom doped graphene-based material supported noble metal nanoparticles are obtained after vacuum drying. The synergistic effect of the heteroatom and the carrier on noble metal is used, the activity and the stability of a catalyst are effectively improved, and a preparation process is simple and suitable for industrial production and has higher economic value.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

A kind of preparation method of the composite ceramics resisting pest

ActiveCN106278280BReduce manufacturing costResistance to PEST phenomenonVacuum pumpingComposite ceramic

The invention discloses a preparation method of PEST resistant composite ceramics. The method comprises the following steps of (1) uniformly mixing C, Si, B, B4C and MoSi2; then, adding bonding agents; performing ball milling, material mixing, compression moulding forming and drying to obtain a blank material; (2) transferring the blank material into a vacuum sintering furnace with Si powder; maintaining the vacuum degree at 10<-2> to 10<-3> Pa; maintaining the temperature rise speed at 1 to 10 DEG C / min; then, performing heat insulation for 5 to 60min at 1400 to 1430 DEG C; then, inflating nitrogen gas or argon gas; raising the temperature to 1450 to 1500 DEG C; performing heat insulation for 5 to 60min; performing vacuum pumping; raising the temperature to 1500 to 1550 DEG C; performing heat insulation for 5 to 40min; finally performing cooling to obtain the composite ceramics. The PEST resistant composite ceramics obtained by the method have low preparation cost and are suitable for industrial mass production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

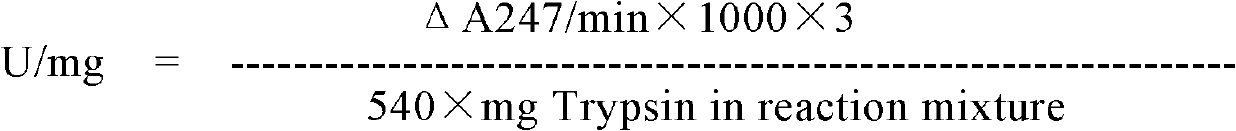

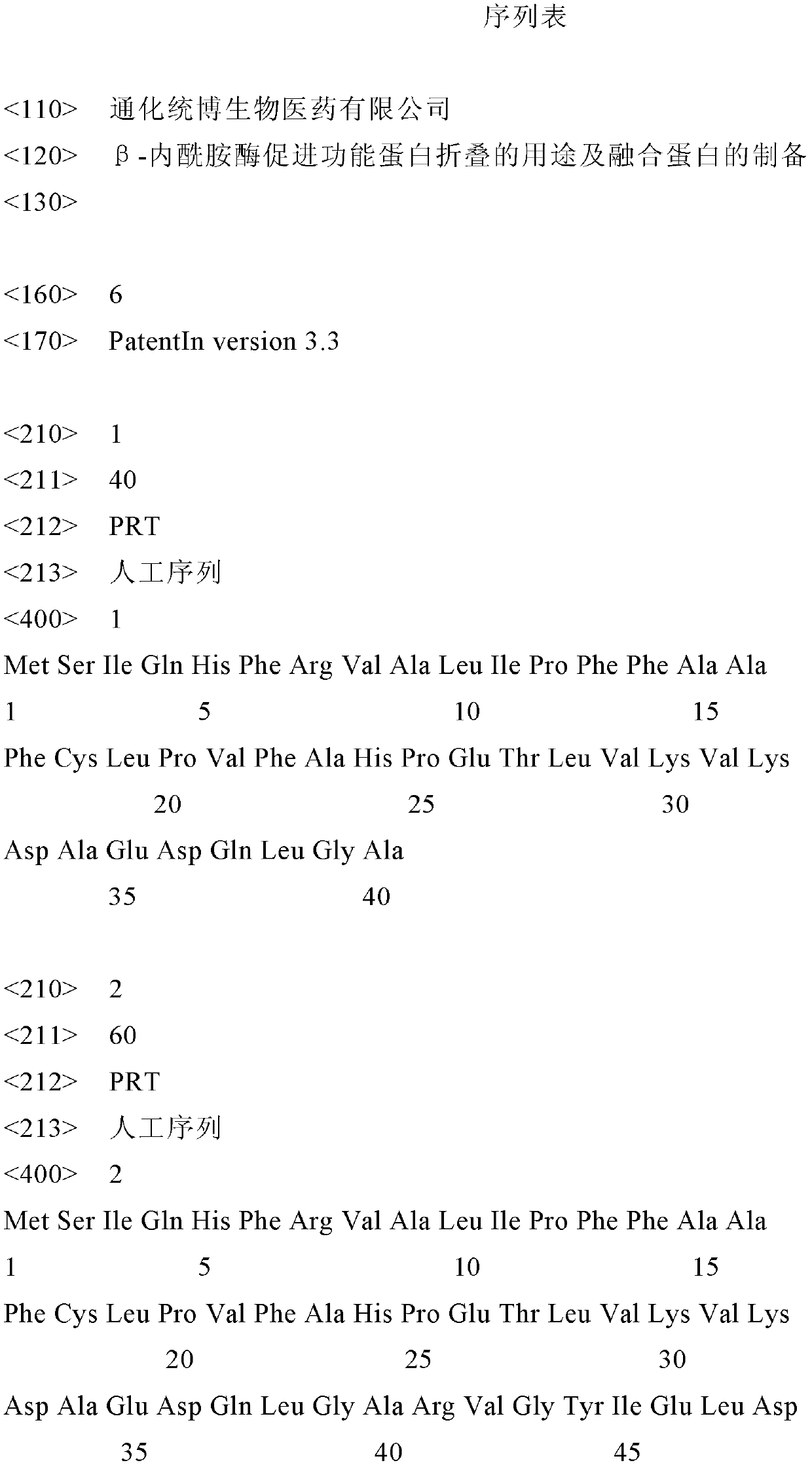

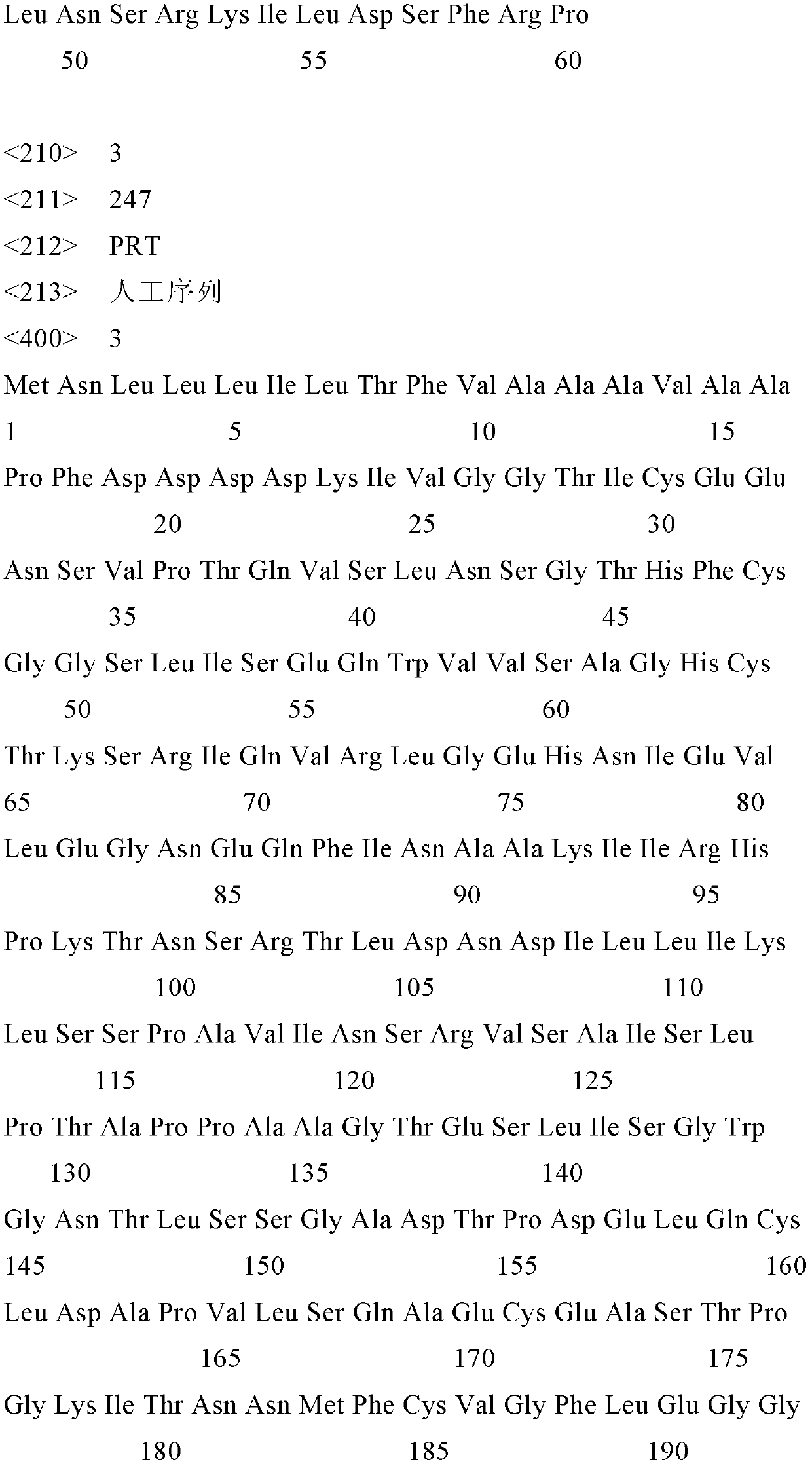

Applications of beta-lactamase in improving functional protein folding and preparation of fusion protein

ActiveCN102321602BQuick foldIncrease productionHydrolasesPeptide preparation methodsProtein precursorFunctional protein

The invention provides applications of beta-lactamase or peptide of which the identity is at least 20% with a beta-lactamase amino acid sequence as leading peptide in improving functional protein folding. One or more of resectable amino acid residues in a leader sequence used in the invention are same with one or more resectable amino acid residues of an isolated leader sequence and a to-be-folded protein precursor, which is good for resecting leader sequence segments after folding, thus the purification steps at the down stream can be simplified, and also the leader protein provided by the invention can improve the folding of functional protein.

Owner:TONGHUA DONGBAO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com