Light emitting diode chip and preparation method of the same

A light-emitting diode and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as crystal defects, LED chip failure, leakage, etc., and achieve the effects of improving service life, enhancing reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

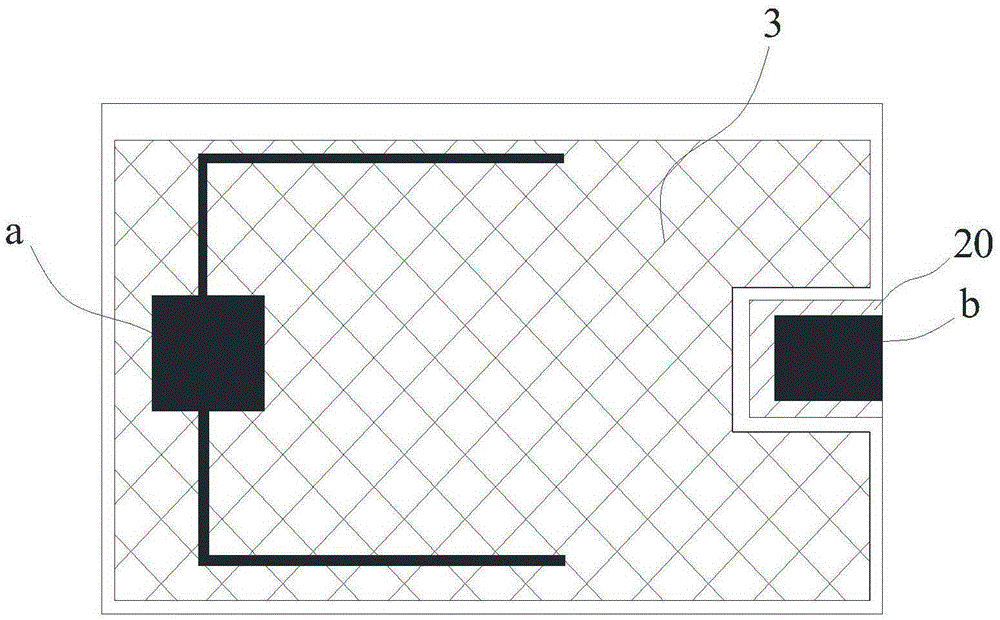

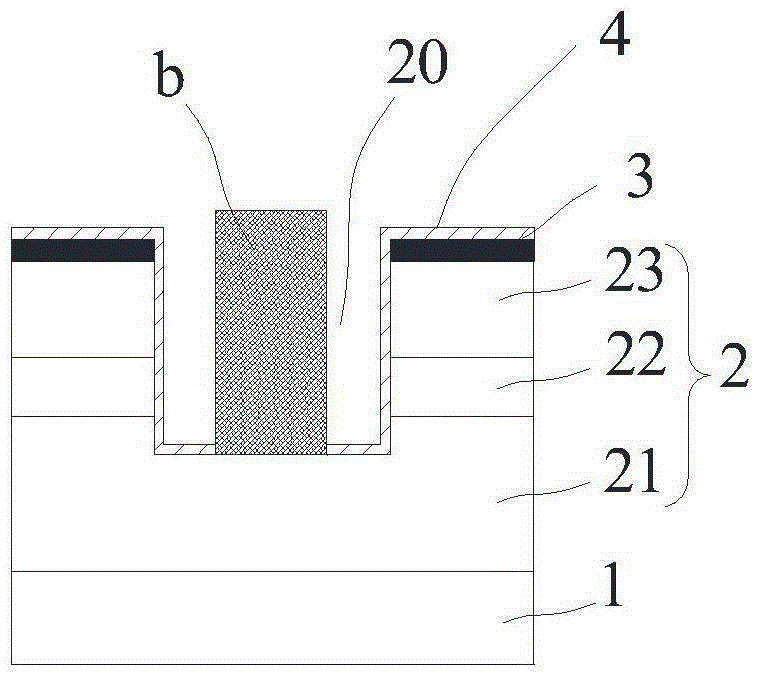

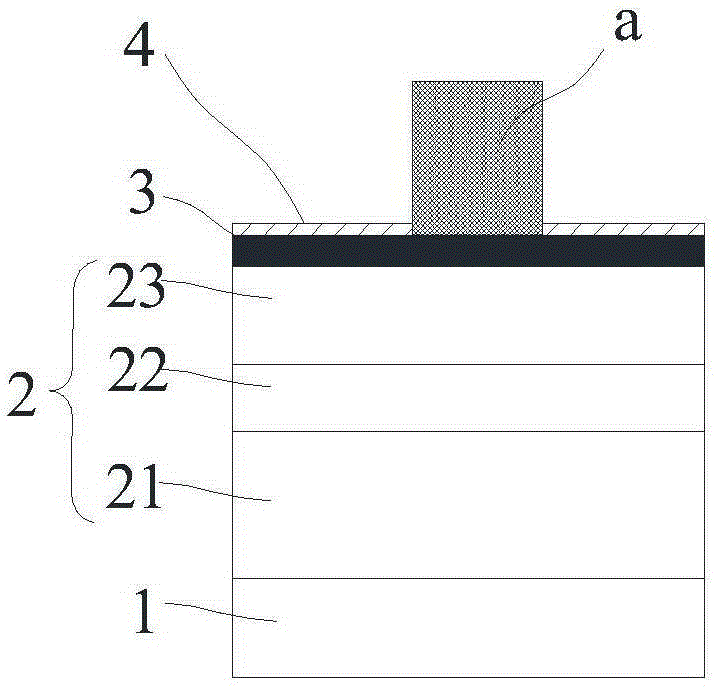

[0050] This example will specifically explain the structure of the light-emitting diode chip provided by the present invention, such as Figure 4 , Figure 5 , Image 6 As shown, it includes a substrate 1, an epitaxial stack 2, a transparent conductive layer 3, an N electrode b and a P electrode a;

[0051] The epitaxial stack 2 includes an N-type semiconductor layer 21, a light-emitting layer 22, and a P-type semiconductor layer 23 deposited sequentially from bottom to top; the N-type semiconductor layer 21 is located above the substrate 1, and the transparent conductive layer 3 Located above the P-type semiconductor layer 23;

[0052] An electrode groove 20 etched from the P-type semiconductor layer 23 to the N-type semiconductor layer 21 is provided on the horizontal centerline of the LED chip;

[0053] The so-called horizontal centerline such as Figure 4 As shown, it is located at the center of the epitaxial stack 2, extending from the left side of the figure to the r...

Embodiment 2

[0071] This example will specifically explain the preparation method of a light-emitting diode chip disclosed in the present invention, such as Figure 7 shown, including the following steps:

[0072] S1, the preparation step of the epitaxial stack 2: depositing the epitaxial stack 2 on the substrate 1; including the N-type semiconductor layer 21, the light-emitting layer 22 and the P-type semiconductor layer 23 deposited sequentially from bottom to top;

[0073] S2, central groove 5 etching steps: as Figure 9 As shown, the central trench 5 that divides the epitaxial stack 2 into two halves is etched (or etched) at the horizontal centerline of the epitaxial stack 2;

[0074] S3, electrode tank 20 etching steps: as Figure 10 As shown, on the horizontal center line of the epitaxial stack 2, an electrode groove 20 is etched from the P-type semiconductor layer 23 to the N-type semiconductor layer 21;

[0075] S4, insulating filler 6 filling steps: such as Figure 11 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com